India Solar Cells - Monocrystalline Solar Cells A Grade -17.8%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

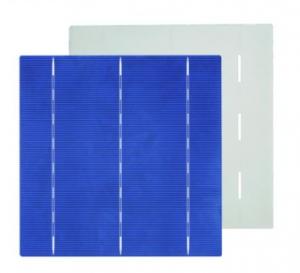

Brief Introduction of Solar Cells

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of ap-n junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Advantage of Monocrystalline Solar Cells

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

Specifications of Monocrystalline Solar Cells

Format : 156 mm × 156 mm ± 0.5 mm

Thickness: 210 μm ±40 μm

Front (-) : 1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride)

Back (+) : 2.5mm wide soldering pads (silver) back surface field (aluminium)

Efficiency (%) Pmpp (W) Umpp (V) Impp (A) Uoc (V) Isc (A) |

18.20% 4.43 0.536 8.263 0.634 8.712 |

18.00% 4.38 0.535 - 8.188 0.633 8.701 |

17.80% - 4.33 0.534 - -8.112 ---0.632 ----8.652 |

17.60% 4.28 0.533 8.036 0.631 8.641 |

17.40% 4.23 0.529 8.005 0.630 8.591 |

17.20% 4.19 0.525 7.973 0.627 8.542 |

17.00% 4.14 0.522 7.926 0.624 8.495 |

16.80% 4.09 0.518 7.893 0.620 8.452 |

16.60% 4.04 0.515 7.844 0.617 8.410 |

16.40% 3.99 0.514 7.765 0.616 8.373 |

16.20% 3.94 0.511 7.715 0.615 8.317 |

16.00% 3.89 0.509 7.650 0.613 8.251 |

Usage of Monocrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Packaging & Delivery of Monocrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

⑥ Can you do OEM for us?

Yes, we can.

- Q: What is the difference between a solar cell and a solar panel?

- A solar cell is a single unit that converts sunlight directly into electricity, while a solar panel consists of multiple solar cells connected together to generate a higher amount of electricity.

- Q: How do solar cells perform in areas with high humidity?

- Solar cells perform slightly less efficiently in areas with high humidity due to the presence of water vapor in the air, which can reduce the amount of sunlight reaching the cells and increase the chances of dust and dirt accumulation. However, advancements in solar cell technology have made them more resistant to humidity, and their performance is still considerable in such areas.

- Q: Can solar cells be used for powering electric water heaters?

- Yes, solar cells can be used to power electric water heaters. By converting sunlight into electricity, solar cells can provide a sustainable and renewable source of energy to heat water in electric water heaters. This helps reduce reliance on traditional grid electricity and lowers carbon emissions.

- Q: Can solar cells be used in schools or educational institutions?

- Yes, solar cells can definitely be used in schools or educational institutions. In fact, they are increasingly being adopted by educational institutions as a way to provide clean and sustainable energy. Solar cells can be installed on rooftops or open spaces in schools to generate electricity, reducing dependency on traditional sources and saving on energy costs. Moreover, incorporating solar cells into the curriculum can also provide students with hands-on learning opportunities about renewable energy and sustainability.

- Q: Can solar cells be damaged by hail or other weather conditions?

- Yes, solar cells can be damaged by hail or other severe weather conditions. Hail can cause physical damage to the surface of solar cells, such as cracks or breakage, which can reduce their efficiency or render them completely non-functional. Additionally, extreme weather conditions like hurricanes or strong winds can also dislodge or damage solar panels, impacting their performance. Therefore, it is essential to consider the durability and resilience of solar panels when installing them in areas prone to severe weather.

- Q: What is the role of inverters in solar cell systems?

- The role of inverters in solar cell systems is to convert the direct current (DC) generated by the solar panels into alternating current (AC) electricity that can be used to power homes and businesses, or be fed back into the electrical grid. Inverters ensure efficient and reliable energy conversion, enabling solar energy to be used effectively as a renewable source of power.

- Q: Can solar cells be used to power water treatment plants?

- Yes, solar cells can be used to power water treatment plants. Solar energy can be converted into electricity using photovoltaic technology, which can then be utilized to power the various systems and processes involved in water treatment, such as pumps, filters, and disinfection systems. Solar power offers a sustainable and environmentally friendly solution for powering water treatment plants, particularly in areas with abundant sunlight.

- Q: What is the impact of solar cell installations on property values?

- The impact of solar cell installations on property values is generally positive. Studies have shown that homes with solar panels tend to sell for higher prices and have faster selling times compared to similar homes without solar installations. Solar energy is becoming increasingly popular and homeowners recognize the financial benefits of reduced energy costs and potential tax incentives. Additionally, solar installations contribute to a more sustainable future, which is an attractive quality for many buyers.

- Q: Can solar cells be used for powering communication towers?

- Yes, solar cells can be used for powering communication towers. Solar panels or cells can generate electricity from sunlight, which can be converted and used to power various electronic devices and equipment, including communication towers. This renewable energy source is increasingly being adopted to reduce reliance on traditional power grids and decrease carbon emissions.

- Q: How does solar cell technology apply to our daily life?

- Through high technology we are using now, solar cell energy is used in our daily life, such as the hot water you are use everyday in taking a shower.

Send your message to us

India Solar Cells - Monocrystalline Solar Cells A Grade -17.8%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords