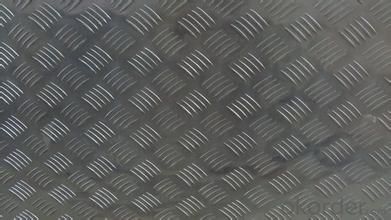

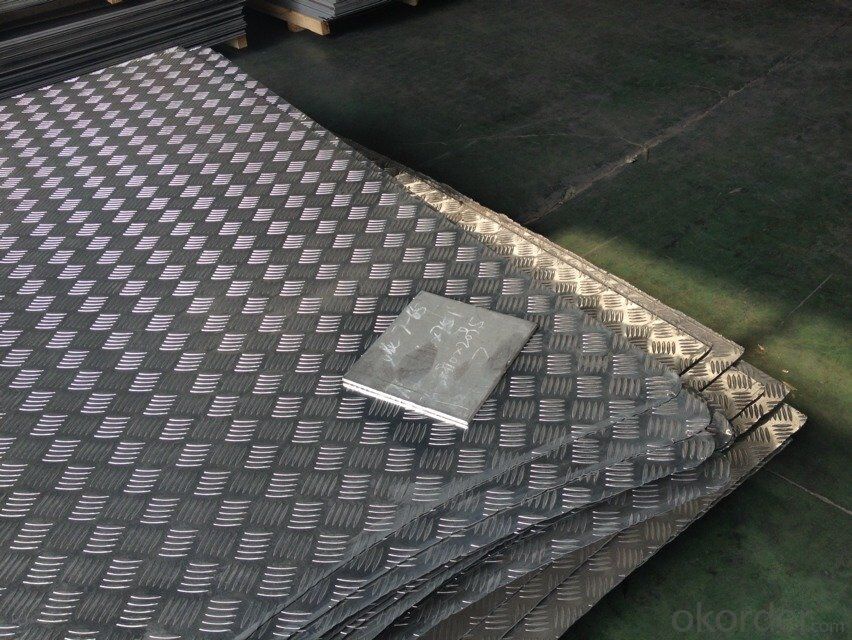

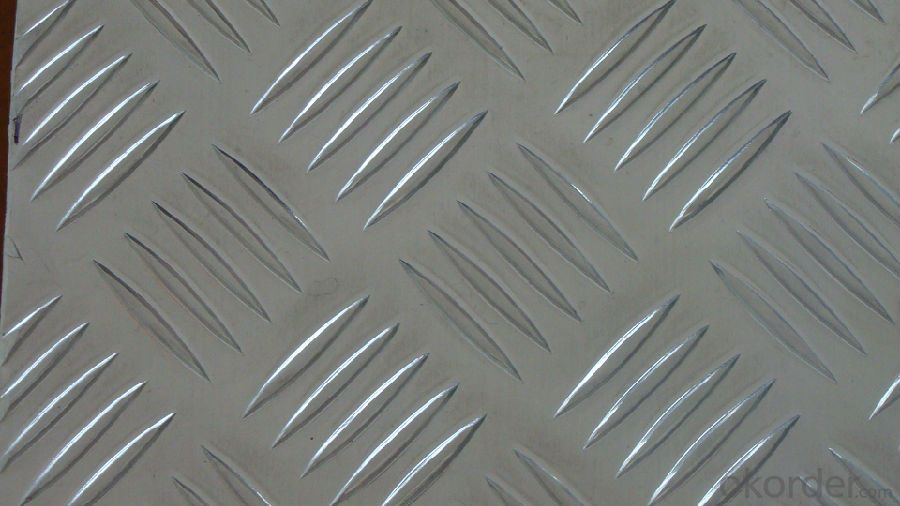

Mill Finished Five Bar Diamond Propeller Aluminum Tread Plate for Anti-Slip - Aluminum Sheets Houston TX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

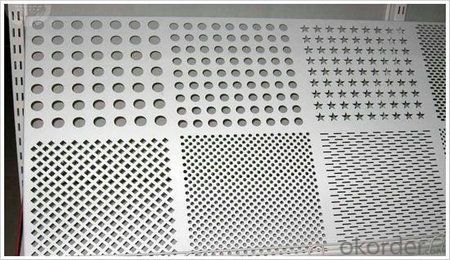

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: This question is asking for a list of different types of fasteners that can be used to attach aluminum sheets to a structure.

- <p>There are several types of fasteners used for attaching aluminum sheets to a structure, including: 1. Rivets: These are permanent fasteners that join two pieces by deforming the rivet material. 2. Screws: These are threaded fasteners that can be inserted and removed as needed. 3. Bolts: Similar to screws, bolts are used with nuts to secure aluminum sheets. 4. Adhesives: Chemical adhesives can be used for bonding aluminum sheets without visible fasteners. 5. Welding: Although not a fastener, welding can join aluminum sheets permanently. 6. Clips and Clamps: These are used for temporary or non-structural attachment. 7. Self-tapping screws: These screws create their own threads in the material being fastened. Each type has its own advantages and is chosen based on the specific requirements of the project.</p>

- Q: What types of aluminum sheets are recommended for outdoor applications?

- <p>Yes, there are specific types of aluminum sheets suitable for exterior use. These include aluminum sheets with a protective coating, such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a Kynar 500庐 PVDF coating are highly resistant to UV rays, making them ideal for exterior applications. Marine-grade aluminum is also recommended for exterior use due to its superior corrosion resistance, especially in coastal areas. These types of aluminum sheets are designed to withstand harsh outdoor conditions and maintain their integrity over time.</p>

- Q: What specific conditions or criteria need to be met when installing aluminum windows to ensure they are properly fitted and functional?

- <p>When installing aluminum windows, there are several special requirements to consider: ensuring the frames are level and square, using the correct size and type of fasteners, applying a proper sealant to prevent air and water infiltration, and adhering to local building codes. Additionally, it's crucial to check for thermal insulation properties, especially in areas with extreme weather conditions. The installation should also allow for proper drainage to prevent water damage. Professional installation is often recommended to meet these requirements and ensure the windows function correctly and last longer.</p>

- Q: does anyone know how much aluminium is recycled per year worldwide compared to how much is produced? Even if you know the stats just for Australia or America it would helpthanksxx

- 45% The fact that they can be recycled to produce more cans means there is no excuse for many people to unaware of aluminum recycling. People should also be aware of the benefits that can occur from it. This has created a strong awareness of the recycling nature of cans and this has been a key factor in the growth of this area. In many canteens, dinner halls and corridors across schools and places of work there is a recycling bin. Wherever people can be found drinking from a soft drink can, a specific aluminum recycling bin can be found for cans to be placed in. Compared to the recycling of many other products, it is easier to find a recycle bin. The provisions for recycling soft drink cans have been more progressively tackled and many people are aware of the need to recycle soft drink cans. This has created awareness and knowledge about recycling and this has moved from school to the outside world. One of the major tactics of marketing departments is to target children and get them to pass the message through to all the family. This is usually done in a bad manner but it can also be done promote recycling. You may see people who go around picking up cans that are thrown away without thought and send them to a recycling center. There are some recycling centers that will make payment for numbers of soft drinks that are recycled. This is a way for people to make some money. It would take a phenomenal amount of aluminum recycling to make a fortune. However, it can help the environment and make a small amount of money back so many people can find the motivation to recycle. There are many places that could be a great source of finding soft drink cans that are thrown away: - School playgrounds - The beach - The car park - Parking lots - Busy streets The amount of products that are available to be recycled continues to grow but it is unlikely that they will grow to be more popular than aluminium recycling.

- Q: i know what aluminum is but oxide is not found on the periodic table, and the teacher also gave us a list of common oxidation numbers for polyatomic ions and it is not there also, can anyone help me?

- Mass Of Aluminum

- Q: What are the different types of surface treatments available for painted aluminum sheets?

- There are several different types of surface treatments available for painted aluminum sheets. These treatments are designed to enhance the appearance and durability of the aluminum, as well as provide protection against corrosion and other forms of damage. One common type of surface treatment is anodizing. Anodizing involves immersing the aluminum sheets in an electrolytic solution and passing an electric current through them. This process creates a protective oxide layer on the surface of the aluminum, which not only improves its corrosion resistance but also provides a base for painting or other decorative finishes. Another popular surface treatment for painted aluminum sheets is powder coating. Powder coating involves applying a dry powder to the surface of the aluminum and then heating it to form a tough, protective layer. This coating is known for its durability, resistance to fading and chipping, and ability to provide a wide range of colors and finishes. In addition to anodizing and powder coating, there are also other surface treatments available for painted aluminum sheets. These include chemical conversion coating, which involves applying a chemical solution to the aluminum to create a protective layer, and laminate coatings, which involve applying a thin film or laminate to the surface for added protection and decoration. Overall, the different types of surface treatments available for painted aluminum sheets offer a variety of benefits, including enhanced appearance, improved durability, and increased resistance to corrosion. The choice of surface treatment will depend on the specific requirements and desired outcomes for the aluminum sheets in question.

- Q: Hello, I dont really know anything about using a drill or cutting through metal or wood. the thing is I have a project in which I have to drill some holes in 0.04in aluminum. but I really dont know if can use regular drill bits used for drilling wood to drill the holes in my aluminum chassis. do I need to buy other drill bits for cutting metal or can I use the same ones Ive seen used for cutting wood? can I even use the same kind of drills, or do I NEED a huge bench drill with stepper bits?thanks

- Aluminum is softer than steel, so you could just use the ordinary bits that you use for wood, with a hand drill. For cleaner holes, you might want to put wood behind the aluminum as a backing. Also, if you squirt a drop of oil onto the drill area, that will help. If you're trying to drill a really large hole, it might be better to drill small ones, and enlarge with a round file.

- Q: What are the different methods for bending aluminum sheets?

- Depending on the desired outcome and available equipment, there are various techniques for bending aluminum sheets. The following are some commonly used methods: 1. Manual Bending: For smaller projects, the aluminum sheet can be manually bent using a manual brake or bending tool. This can be achieved by hand with the assistance of clamps or a simple bending tool. 2. Press Brake: In industrial settings or for larger-scale projects, a press brake machine is utilized. It applies significant force through a punch and die set to create precise and consistent bends. 3. Roll Bending: To achieve long, continuous bends or curves, the aluminum sheet is passed through a series of rollers in the roll bending method. This technique is commonly employed in the production of cylindrical or conical shapes. 4. Rotary Bending: Thin aluminum sheets are effectively bent into curves using rotary bending. This method involves a rotating roller or wheel along the length of the sheet to create smooth and uniform bends. 5. Heat Bending: Thicker aluminum sheets or complex shapes often require heat bending. The sheet is heated to a specific temperature to enhance its malleability before being bent into the desired shape. It is crucial to consider factors such as aluminum thickness and alloy, desired bend angle and radius, and available equipment when choosing the appropriate bending method. Consulting professionals or referring to specific guidelines is recommended for optimal results.

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated. Powder coating is a popular finishing process that involves applying a dry powder to a surface, such as aluminum, and then curing it through heat to create a durable and attractive finish. Aluminum is commonly powder coated due to its lightweight, corrosion-resistant, and versatile nature. The powder coating process provides excellent adhesion to aluminum sheets, resulting in a smooth, even, and long-lasting finish. It also offers a wide range of color options and can be used for various applications, including architectural, automotive, and industrial uses.

- Q: What are the different methods of surface cleaning aluminum sheets?

- There are several different methods for surface cleaning aluminum sheets, including chemical cleaning, mechanical cleaning, and electrolytic cleaning. Chemical cleaning involves using solutions or acids to remove dirt, oxidation, or other contaminants from the surface of the aluminum. Mechanical cleaning involves scrubbing or abrasive techniques to physically remove dirt or grime from the surface. Electrolytic cleaning utilizes an electric current and an electrolyte solution to remove contaminants and create a clean surface on the aluminum sheets.

Send your message to us

Mill Finished Five Bar Diamond Propeller Aluminum Tread Plate for Anti-Slip - Aluminum Sheets Houston TX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords