Mill Finished Directed Rolled Aluminum Strip AA3004 - Aluminum Sheets for Sale Mercer County

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Mill Finished Hot Rolled Aluminium Strip is one semi-finished aluminium material.For the Alloy AA3004 is widly used in beer cans industry. Its weight is much lower than steel. Moreover, aluminium material can be anti-rust and re-cycle during the industry process. So aluminium have instead of steel in the beer can industry.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

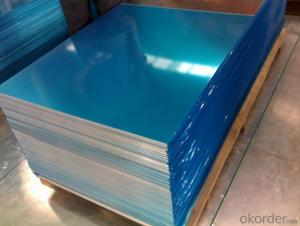

3. Image:

4.Products Specification

| Alloy | Thickness | Coil ID | Coil Weight | Main Usage |

| AA5052 | 0.2mm-3mm | 508mm+/-10mm | 2-2.5 tons | Ships |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are the aluminum sheets suitable for manufacturing lighting fixtures?

- Yes, aluminum sheets are suitable for manufacturing lighting fixtures. Aluminum is a lightweight and versatile material that offers several advantages for lighting fixture manufacturing. Firstly, aluminum is known for its excellent thermal conductivity, meaning it can effectively dissipate heat generated by the lighting components. This helps in prolonging the lifespan of the lighting fixtures and maintaining their efficiency. Additionally, aluminum is corrosion-resistant, which is crucial for lighting fixtures as they are often exposed to different environmental elements. This property ensures that the fixtures will not degrade over time and can withstand outdoor conditions. Moreover, aluminum sheets can be easily formed into various shapes and sizes, allowing manufacturers to create customized designs for lighting fixtures. This versatility makes aluminum an ideal choice for both functional and aesthetic lighting applications. Furthermore, aluminum is a sustainable and eco-friendly material. It is recyclable, reducing the environmental impact of manufacturing processes. This makes aluminum sheets a popular choice for manufacturers that prioritize sustainability in their operations. Overall, the excellent thermal conductivity, corrosion resistance, versatility, and sustainability of aluminum sheets make them highly suitable for manufacturing lighting fixtures.

- Q: What is the typical machinability of aluminum sheets?

- The typical machinability of aluminum sheets is considered to be excellent. Aluminum is known for its softness and low density, which makes it relatively easy to machine. It can be cut, drilled, and formed with relative ease, allowing for efficient and precise machining processes. However, the specific machinability of aluminum sheets can vary depending on factors such as alloy composition, temper, and thickness.

- Q: Can the aluminum sheets be used for manufacturing chemical piping systems?

- Indeed, the utilization of aluminum sheets in the production of chemical piping systems is plausible. Renowned for its remarkable resistance against corrosion, aluminum proves to be apt for handling an array of chemicals. Moreover, its lightweight nature facilitates effortless installation and maintenance procedures. Furthermore, aluminum possesses commendable thermal conductivity, thereby enabling efficient heat transfer within chemical processes. Nonetheless, it is crucial to contemplate the distinctive demands imposed by the chemicals being conveyed and seek guidance from specialists to guarantee the selection of aluminum sheets equipped with indispensable properties and compatibility with the chemicals to be employed within the piping system.

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically consists of 99.5% pure aluminum with trace amounts of other elements such as iron and silicon.

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Aluminum is a relatively soft metal, which makes it easier to polish compared to harder metals like stainless steel. Polishing aluminum sheets involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections, scratches, or oxidation on the surface. The process typically involves several stages of polishing with different grits of sandpaper or polishing compounds, gradually achieving a smoother and more reflective surface. Polished aluminum sheets are commonly used in various applications, including automotive parts, architectural elements, and decorative items, as the polishing process enhances the metal's appearance and provides a lustrous and reflective finish.

- Q: This question asks for a guide on the correct procedure to install aluminum sheets, likely for construction or renovation purposes.

- <p>To install aluminum sheets properly, follow these steps: 1. Prepare the surface by cleaning and leveling it. 2. Measure and cut the aluminum sheets to the required size using a metal saw or tin snips. 3. Apply a bead of construction adhesive along the edges of the surface where the sheets will be placed. 4. Position the aluminum sheet, ensuring it's aligned correctly. 5. Secure the sheet with screws or nails, using a washer to prevent tearing. 6. Seal the seams and edges with a weatherproof sealant to prevent water ingress. 7. Inspect the installation for any gaps or unevenness and make adjustments as needed. Always follow the manufacturer's guidelines and safety precautions while working with aluminum sheets.</p>

- Q: Can 101 aluminum sheets be used in the construction industry?

- Yes, 101 aluminum sheets can be used in the construction industry.

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a commonly used material for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion.

- Q: i keep hearing all these things about burning aluminum foil and such

- Yes, aluminum is a soft metal andit will not hold up well in a fire and if it's a hot fire you don't want to breathe in any fumes the rim might give off. If you want to use a rim, best to use steel. Or like the other guy said, rocks or bricks.

Send your message to us

Mill Finished Directed Rolled Aluminum Strip AA3004 - Aluminum Sheets for Sale Mercer County

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords