1100 Series Mill Finished Aluminum Coils Without Coating for Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

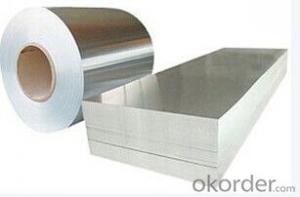

1.Structure of Mill Finished Aluminium Coils without Coating for Package

Mill Finished Aluminium Coils without Coating for Package is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Coils without Coating for Package

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Mill Finished Aluminium Coils without Coating for Package

4. Product Specification of Mill Finished Aluminium Coils without Coating for Package

| ALLOY | TEMPER | THICKNESS | ROLLING | WEIGHT |

| AA1050 | H18 | 0.2MM-3MM | CONTINUOUS | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered. However, the process for each differs significantly. Welding aluminum typically involves using a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process, which requires a high heat source and a filler material to join the sheets together. The process can be more challenging compared to welding steel due to aluminum's high thermal conductivity and lower melting point. Soldering aluminum, on the other hand, is a process that involves using a low-temperature solder and flux to bond the sheets together. Specialized solders, such as aluminum solder or solder with a high percentage of tin, are typically used. Soldering aluminum is generally less common and more difficult compared to soldering other metals due to aluminum's oxide layer, which can prevent proper adhesion. In summary, while both welding and soldering can be used to join aluminum sheets together, welding is the more commonly used method due to its stronger and more durable results. Soldering aluminum can be more challenging due to the need for specialized solders and the presence of the oxide layer.

- Q: Fiber laser cutting machine and carbon dioxide laser cutting machine, which thin aluminum plate effect is better?

- If it is a thin aluminum plate, it is better to use the fiber laser cutter. Fiber laser cutting machine is mainly to cut thin metal, CO2 cutting machine is mainly cutting non-metallic or very thick metal. You can see the families:

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion due to their hardness and durability.

- Q: Can 101 aluminum sheets be welded?

- Yes, 101 aluminum sheets can be welded.

- Q: What are the different methods of surface texturing aluminum sheets?

- Aluminum sheets can be textured in various ways, each with its own advantages and applications. 1. Mechanical Texturing involves using mechanical tools or processes, like brushing, sanding, or embossing, to create patterns or textures on the surface of aluminum sheets. This method is commonly used to achieve a matte or brushed finish, enhancing the appearance and concealing imperfections. 2. Chemical Texturing involves using chemicals to etch the surface of aluminum sheets and create unique patterns or textures. Acid etching, for example, selectively dissolves the surface to create a textured effect. This method is often employed to improve adhesive properties, making the sheets suitable for bonding or coating applications. 3. Anodizing is an electrochemical process that forms a controlled oxide layer on the surface of aluminum sheets. It can create various textures, ranging from smooth and glossy to rough and matte. Anodizing not only enhances the appearance but also improves corrosion resistance and durability. It is commonly used in architecture, consumer products, and automotive parts. 4. Laser Texturing utilizes laser technology to create precise and intricate patterns or textures on aluminum sheets. Laser beams can be accurately controlled to remove material or modify the surface, allowing for highly customized and detailed textures. This method is often utilized in high-end applications, such as jewelry, signage, or interior design. Each texturing method offers unique benefits and is suitable for different applications. The choice depends on factors such as desired texture, durability requirements, aesthetic preferences, and intended use of the aluminum sheets.

Send your message to us

1100 Series Mill Finished Aluminum Coils Without Coating for Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords