Aluminum Coil 5052 Price - Mill Finish Coil 5052 Aluminum Alloy Properties

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

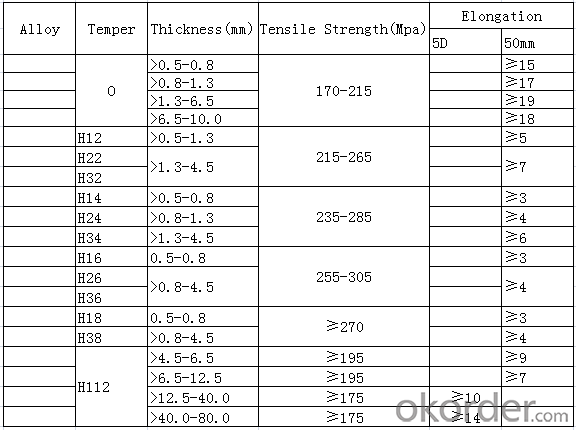

Mill Finish Coil 5052 Aluminum Alloy Properties

l Product Description

Aluminum Coil - Specifications

- Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

Aluminum Coil - Tolerances

- Manufactured in compliance with the main international specification and standards.

- Tighter tolerances are available upon request.

Aluminum Coil - Surface Conditions

- Mill, Matte, Bright and Brushed

- Cleaning and degreasing

- Surface oiling

- Customized surface conditions available upon request.

Aluminum Coil - Special Processing

- Cut-to-Length

- Tension Leveling

- Paper Interleaving

- Fine grain, minimum earring, anodizing quality

l Product Specification:

The Composition Aluminium Coil 5052

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

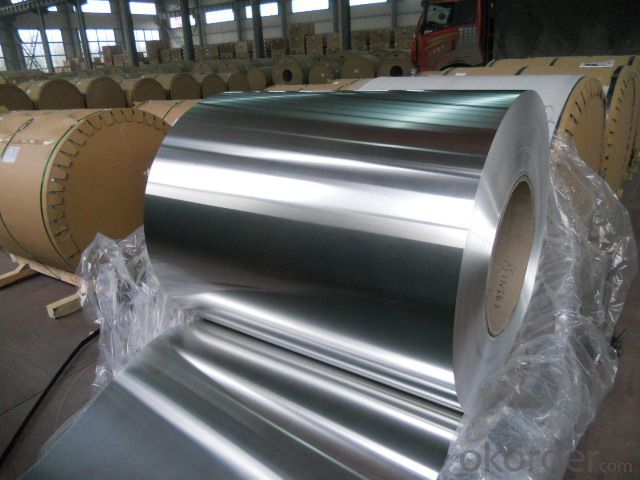

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: The canoe is aluminum. It has some paint remaining on it from what i am assuming is the original factory paint. The paint is just in patches, so my question is do i sand only where the paint is, or the whole canoe? Will sanding the aluminum damage it? Or should I not sand it at all, and just use paint stripper? After getting the old paint off, what kind of primer should i use? or is it not necessary to prime? What kind of paint should I use? I plan on it being multi tone(a leafy camo, of olive drab, flat black, and a gray tone).

- Go to a paint trade shop tell them what your trying to achieve. They will probably suggest a primer to etch the aluminium. Once its been etched you can paint it any colour you wish. If you don't etch the aluminium, the paint will probably fall off. The etching gives the paint something to adhere to. Cheers!!

- Q: What are the necessary safety measures one should take while using aluminum coils in a kitchen setting?

- <p>When using aluminum coil in a kitchen, safety precautions include: 1) Ensuring proper ventilation to avoid inhaling fumes, as aluminum dust can be harmful. 2) Wearing protective gear such as gloves and goggles to protect your skin and eyes from potential contact with aluminum or sharp edges. 3) Handling the aluminum coil carefully to prevent cuts or injuries. 4) Avoiding contact with acidic or alkaline substances, as aluminum can react with them. 5) Not using aluminum coil near open flames or high heat sources, as it can melt or cause fires. 6) Cleaning up any aluminum dust or debris promptly to prevent slipping hazards. 7) Storing aluminum coils in a dry, cool place away from chemicals and heat sources.</p>

- Q: Can aluminum coils be used in food processing or packaging applications?

- Yes, aluminum coils can be used in food processing or packaging applications. Aluminum is a widely used material in the food industry due to its excellent properties such as corrosion resistance, light weight, and heat conductivity. It is commonly used for wrapping food, creating food containers, and in the form of coils for various food processing applications. Aluminum coils are often used for packaging perishable food items like meat, dairy products, and beverages. The coils can be easily formed into different shapes and sizes to meet specific packaging requirements. Aluminum's excellent barrier properties help protect the food from moisture, oxygen, and light, ensuring longer shelf life and maintaining food quality. In food processing, aluminum coils are utilized in various equipment such as heat exchangers, evaporators, condensers, and refrigeration systems. Aluminum's thermal conductivity allows for efficient heat transfer, making it suitable for applications that require precise temperature control. Furthermore, aluminum is non-toxic and does not react with food, making it a safe and hygienic choice for food processing and packaging. It is also recyclable, making it an environmentally friendly option. Overall, aluminum coils are widely accepted and used in food processing and packaging applications due to their versatility, durability, and suitability for maintaining the quality and safety of food products.

- Q: To put aluminum heads on my car do i have to add other things or basically can i just get them and put them on

- Aluminum heads will warp the first time the engine accidentally overheats. Why would you go with aluminum?

- Q: Hey everybody I'm trying to improve the performance of my vintage metal Coleman cooler I just got. To test it I filled it up with water bottles and 5lbs of cubed ice from Stop and Shop and left it in the closet with the dorm's AC set to 65. When I got back 28 hours later the ice was completely melted. The water still kept the drinks cool for several days after that, but I'm frustrated that the ice melted in a single day.

- Aluminum foil has zero R factor (insulation factor). However, if it put on the outside of a cooler it will reflect the sun rays away from the cooler, and make it easier for your cooler to keep things cool. Gel packs are slightly better than extra ice (depending on the amount/concentration of glycol alcohol in them) -- gel packs are popular because they are self contained and not as wet and messy as melted ice. Edit: Well, indoors the aluminum would not be a complete waist. Heat waves from inside the house would still bounce off the aluminum. But the other answerer mentioned a very good way to further insulate your cooler. Just attach (tape or glue) stryrofoam sheets to the outside of your cooler == that would be a big time improvement.

- Q: Can aluminum coils be used in the production of consumer electronics?

- Yes, aluminum coils can be used in the production of consumer electronics. Aluminum coils are commonly used in various electronic devices, such as smartphones, laptops, and televisions, due to their lightweight, high conductivity, and thermal efficiency properties. They are used in components like heat sinks, connectors, and circuit boards to ensure efficient heat dissipation and electrical conductivity, thereby enhancing the performance and reliability of consumer electronics.

- Q: if air goes throught a lot of tiny aluminum will cause cooling? Why am i asking this because when you see inside the computer desktop has heatsink fan, and some of the heatsink are made by aluminum.

- The aluminium heatsink absorbs the heat from the component it is connected to, the heatsink will have a very large surface area-to-volume and the heat will pass into the air due to this. so you can see its not actualy the metal that causes cooling, the metal just transfers the heat to the air where it will be taken away by fans etc.

- Q: What are the potential health risks associated with aluminum coils?

- Aluminum coils find common usage in HVAC systems due to their durability and excellent heat transfer properties. Although they are generally regarded as safe, there exist potential health hazards associated with aluminum coils if specific conditions are not met. One primary concern is the possibility of aluminum leaching into the air or water supply. Aluminum is a known neurotoxin, and prolonged exposure to it can result in various health problems, especially in individuals with pre-existing conditions like kidney disease or weakened immune systems. However, the quantity of aluminum that typically leaches from coils is minimal and unlikely to pose a significant risk to most people. Another potential health hazard pertains to the buildup of dust, dirt, and other particles on the aluminum coils. These particles can serve as a breeding ground for bacteria, mold, and other allergens, negatively impacting indoor air quality. If not adequately maintained and cleaned, these contaminants can lead to respiratory issues, allergies, and even infections in susceptible individuals. Moreover, aluminum coils can generate electromagnetic fields (EMFs) due to the electric currents passing through them. While the health effects of EMF exposure are still subject to ongoing research, certain studies indicate a potential connection between high levels of EMFs and specific health conditions, including cancer. However, it is essential to note that the levels of EMFs emitted by aluminum coils are generally deemed to be within safe limits and unlikely to present significant health risks. To mitigate these potential health hazards, it is crucial to ensure proper maintenance and cleaning of aluminum coils. Regular inspections, professional cleaning, and frequent air filter changes can help prevent the buildup of contaminants and maintain good indoor air quality. Additionally, it is advisable to consult with HVAC professionals to guarantee proper installation and maintenance of the coils, minimizing the risk of aluminum leaching or excessive EMF exposure. In conclusion, although potential health risks are associated with aluminum coils, they are typically considered safe when adequately maintained. By taking necessary precautions and adhering to recommended maintenance practices, it is possible to minimize any potential health concerns related to aluminum coils in HVAC systems.

- Q: This question asks for methods to prevent corrosion on aluminum coils during storage or transportation.

- <p>To prevent corrosion on aluminum coils during storage or transportation, follow these steps: 1. Store the coils in a dry, clean environment to avoid moisture and dirt. 2. Use protective wrapping or covers to shield the coils from moisture and contaminants. 3. Ensure proper ventilation in storage areas to prevent condensation. 4. Avoid stacking coils directly on the ground; use pallets or racks to keep them off damp surfaces. 5. Handle the coils carefully to prevent scratches or damage that could lead to corrosion. 6. Regularly inspect the coils for signs of corrosion and address any issues promptly. 7. Consider using anti-corrosion coatings or treatments on the coils if they will be stored for extended periods. By following these guidelines, you can minimize the risk of corrosion and maintain the integrity of your aluminum coils.</p>

- Q: How do aluminum coils contribute to thermal insulation in buildings?

- Aluminum coils contribute to thermal insulation in buildings by acting as a barrier against heat transfer. These coils are often used in HVAC (heating, ventilation, and air conditioning) systems to ensure efficient cooling and heating. The aluminum material has a high thermal conductivity, which allows it to quickly absorb and dissipate heat. By regulating the temperature, aluminum coils help in maintaining a comfortable indoor environment while reducing energy consumption and associated costs. Additionally, they are lightweight and corrosion-resistant, making them a durable and cost-effective choice for thermal insulation in buildings.

Send your message to us

Aluminum Coil 5052 Price - Mill Finish Coil 5052 Aluminum Alloy Properties

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords