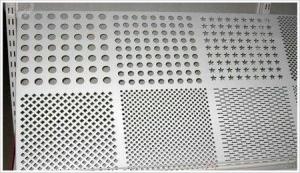

Mill Finish Aluminum Foil Sheets With Holes 1xxx 3xxx 5xxx Series for ACP Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

1.Structure of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

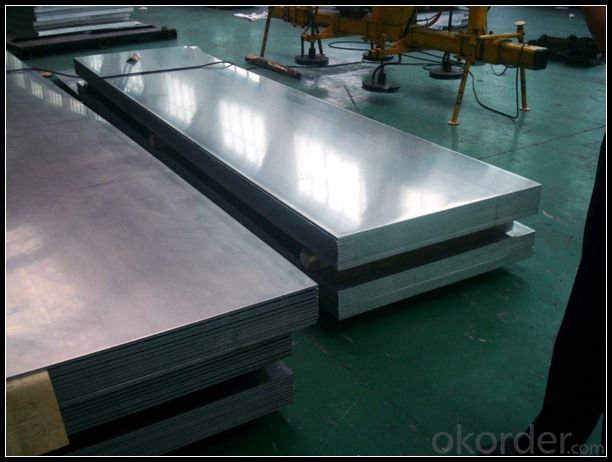

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

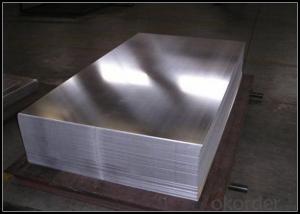

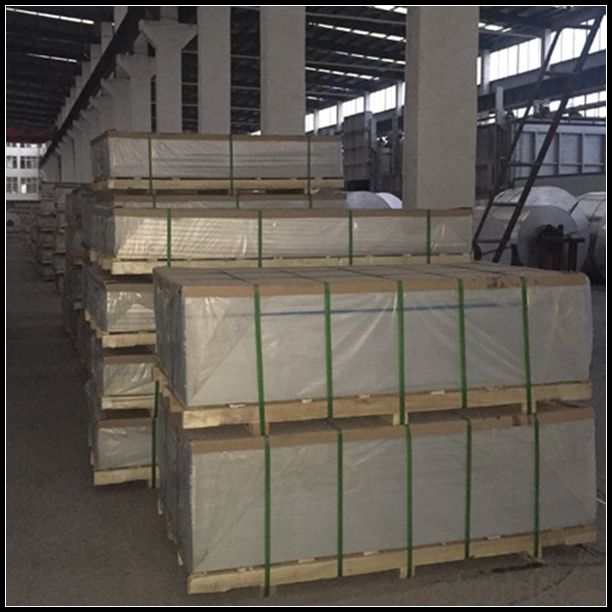

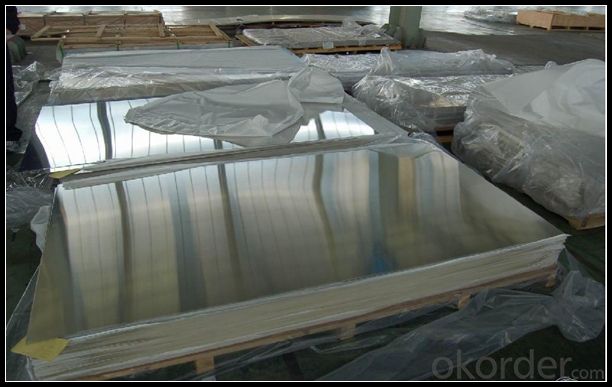

3. Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board Images

4.Specification of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

Alloy Number | AA1XXX 3XXX 5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminium Sheet 1xxx 3xxx 5xxx Series for ACP Board

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: So my new farrier comes out tomorrow and charges $20 more for aluminum shoes and I was wondering why that is? Is one better than the other? My horse is a TB hunter jumper. Tell me what you think :)

- Aluminum has no wearability. Steel shoes can be re-set a number of times, which can save you money. If you ride your horse out on trails at all, you'll go through shoes like crazy. Aluminum is such soft metal that it's really not practical for most horses.

- Q: This question asks about the impact of using aluminum sheets on the aesthetic appeal of a building.

- <p>Aluminum sheets can significantly enhance the appearance of a building due to their versatility, durability, and modern aesthetic. They offer a sleek, clean look and can be easily shaped into various designs, adding a contemporary feel. The material's resistance to corrosion and weathering ensures that the building maintains its appearance over time. Additionally, aluminum sheets can be coated with various colors and finishes, allowing for customization and the ability to blend with or stand out from the surrounding architecture.</p>

- Q: the aluminium pull tabs are in a jucy juice bottle

- 82% okorder /

- Q: Can the aluminum sheets be used for manufacturing architectural sunshades?

- Yes, aluminum sheets can be used for manufacturing architectural sunshades. Aluminum is a popular material choice for sunshades due to its lightweight nature, durability, and resistance to corrosion. It can be easily fabricated into different shapes and sizes, allowing for flexibility in design. Additionally, aluminum has excellent heat reflectivity properties, making it effective in reducing solar heat gain and providing shade to buildings. Overall, aluminum sheets are a suitable material for manufacturing architectural sunshades.

- Q: Can aluminum sheets be used for heat lamps?

- Indeed, heat lamps can utilize aluminum sheets as they possess remarkable heat conductivity. This quality enables aluminum to efficiently transmit and disperse heat, rendering it suitable for heat lamps that necessitate proficient heat distribution for effective warming of objects or spaces. Furthermore, the lightweight nature, durability, and high melting point of aluminum make it a practical and sensible option for heat lamp purposes.

- Q: Can aluminum sheets be stamped or pressed?

- Yes, aluminum sheets can be stamped or pressed. Aluminum is a highly malleable metal that can be easily shaped and formed through various manufacturing processes. Stamping and pressing are commonly used techniques to create intricate designs, shapes, and patterns on aluminum sheets. These processes involve applying pressure to the sheet using specialized equipment, such as stamping presses or hydraulic presses, to deform the material and create the desired shape. Stamping and pressing are widely used in industries such as automotive, aerospace, construction, and manufacturing, where aluminum sheets are often used for their lightweight, durable, and corrosion-resistant properties.

- Q: Can the aluminum sheets be used for manufacturing door frames?

- Yes, aluminum sheets can be used for manufacturing door frames.

- Q: I put the aluminum in copper chloride for an experiment and i was wondering if they had different properites.

- Yes, Rust is an Oxide of iron which can be broken down chemically into simpler substances. Aluminium is a pure Element which cannot be broken down chemically or physically into other substances.

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q: 10mm how much is the aluminum sheet?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liaoning Wang Zhong Nanshan aluminum do this thickness.

Send your message to us

Mill Finish Aluminum Foil Sheets With Holes 1xxx 3xxx 5xxx Series for ACP Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords