Mill Finish Aluminum Coil for Subwoofer Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Coil for Color Coating

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Mill Finish Aluminium Coil for Color Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Coil for Color Coating

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

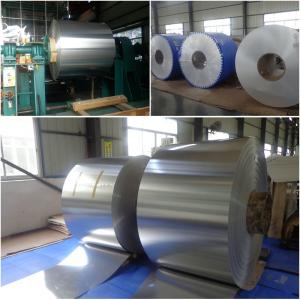

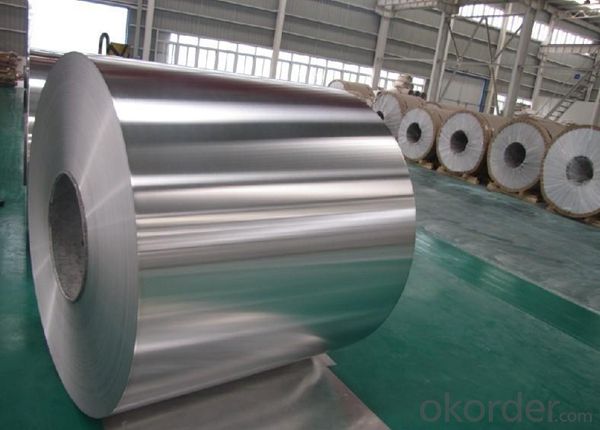

5. Image of Mill Finish Aluminium Coil for Color Coating

6. Package and shipping of Mill Finish Aluminium Coil for Color Coating

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the hardness range of aluminum coils?

- The hardness range of aluminum coils typically falls between 40 and 70 on the Rockwell hardness scale.

- Q: Are aluminum coils compatible with different joining methods?

- Different joining methods can be used with aluminum coils. Aluminum, a versatile metal, can be joined using techniques like welding, brazing, soldering, and mechanical fastening. The choice of method depends on the specific application and desired joint properties. To join aluminum coils, welding is commonly used as it creates a strong and durable bond. Various welding techniques, such as MIG, TIG, and resistance welding, can be employed based on the thickness and alloy type. Brazing is another effective method for joining aluminum coils. It involves heating a filler material with a lower melting point than the base metal to create a strong joint. Brazing is suitable when joining aluminum coils with dissimilar metals. For thin aluminum coils or when a lower temperature method is necessary, soldering is a suitable option. It involves melting a low-temperature alloy (solder) to join the coils together. Soldering finds common use in electronics and plumbing applications. Mechanical fastening methods like bolts, screws, rivets, or clips can also be used to join aluminum coils. These methods provide a reliable and removable joint, making them appropriate for applications requiring disassembly. In conclusion, different joining methods, including welding, brazing, soldering, and mechanical fastening, can be used with aluminum coils. The choice depends on factors like the application, alloy type, and desired joint properties.

- Q: How do aluminum coils compare to ceramic coils in terms of thermal conductivity?

- Aluminum coils have significantly higher thermal conductivity compared to ceramic coils.

- Q: How are aluminum coils used in the production of furniture?

- Aluminum coils are widely used in the production of furniture due to their various beneficial properties. These coils are typically made from high-quality aluminum alloy, which offers excellent corrosion resistance, durability, and lightweight characteristics. In the furniture manufacturing process, aluminum coils are primarily used for creating the framework or structure of the furniture pieces. They are often formed into various shapes and profiles to provide the necessary strength and rigidity required for the furniture item. The coils can be easily bent, cut, and joined together to create different components such as chair frames, table legs, or cabinet structures. This versatility allows manufacturers to design and produce furniture with intricate and customized shapes and sizes. Moreover, aluminum coils are highly adaptable to different finishing techniques. They can be anodized, painted, or powder-coated to enhance their aesthetic appeal and provide additional protection against wear and tear. This makes aluminum-coiled furniture resistant to scratches, stains, and fading, ensuring longevity and a visually appealing appearance. Additionally, aluminum coils offer a lightweight alternative to other materials like steel or wood, making furniture easier to transport and handle. This is particularly advantageous in the case of outdoor furniture or pieces that need to be frequently moved or rearranged. Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, allowing manufacturers to reduce their carbon footprint and contribute to a more sustainable production process. In summary, aluminum coils play a vital role in the production of furniture by providing strength, durability, versatility, and aesthetic appeal. Their use in furniture manufacturing helps create lightweight, customizable, and sustainable furniture pieces that meet the demands of modern consumers.

- Q: How are aluminum coils used in the production of architectural structures?

- Due to their advantageous properties, aluminum coils play a crucial role in the production of architectural structures. Their lightweight, strength, and corrosion resistance make them highly valued in the construction industry. Roofing systems in architectural structures commonly utilize aluminum coils. The lightweight nature of aluminum makes installation easy and reduces the overall load on the building. Additionally, aluminum's corrosion resistance ensures that the roofing system remains durable and long-lasting, regardless of weather conditions. Aluminum coils are also employed in the creation of exterior cladding systems. Their ability to be formed into various shapes and sizes allows for the development of unique and visually appealing architectural designs. Furthermore, aluminum's resistance to corrosion and ability to withstand harsh environmental factors make it an ideal choice for cladding systems, guaranteeing the structure's longevity and aesthetics. Windows and doors in architectural structures often incorporate aluminum coils in their production. The lightweight properties of aluminum make handling and installation effortless, while its high strength provides structural integrity to these components. Furthermore, aluminum's corrosion resistance results in long-lasting windows and doors that require minimal maintenance. In summary, aluminum coils are an essential component in the production of architectural structures. Their lightweight, strength, and corrosion resistance make them the preferred choice for roofing, cladding, windows, and doors. By utilizing aluminum coils, architects and builders can create sustainable structures that are durable, aesthetically pleasing, and withstand the test of time.

- Q: What are the common surface finishes for aluminum coils in the electrical industry?

- The common surface finishes for aluminum coils in the electrical industry include mill finish, anodized finish, and painted finish.

- Q: Can aluminum coils be used in automotive manufacturing?

- Automotive manufacturing can indeed utilize aluminum coils. Aluminum, a versatile and lightweight substance, presents several advantages within the automotive sector. Frequently employed for fabricating components such as body panels, engine blocks, wheels, and heat exchangers, aluminum's incorporation in automotive manufacturing enhances fuel efficiency by reducing vehicle weight and subsequently minimizing energy consumption. Furthermore, aluminum boasts exceptional resistance to corrosion, rendering it appropriate for deployment in diverse weather conditions. In conclusion, the extensive benefits associated with the utilization of aluminum coils in automotive manufacturing have led to its widespread adoption by numerous car manufacturers.

- Q: Can aluminum coils be used in the manufacturing of medical devices?

- Yes, aluminum coils can be used in the manufacturing of medical devices. Aluminum is a lightweight and corrosion-resistant material that can be easily formed into coils, making it suitable for various medical applications such as imaging equipment, surgical instruments, and prosthetics.

- Q: Is it possible to utilize aluminum coils for the purpose of storage?

- <p>Yes, aluminum coils can be used for storage, particularly in industrial settings. They are often used for storing materials such as paper, plastic films, and other coilable products. Aluminum coils are lightweight, corrosion-resistant, and can be easily transported and handled. They are also recyclable and environmentally friendly. However, their suitability for storage depends on the specific application and the type of material being stored. It's important to ensure that the coils are stored in a dry, clean environment to prevent damage and maintain their integrity.</p>

- Q: Is there any elements that can be added to aluminum to create any compound?

- yes: Aluminum Chloride which is AlCl3. Aluminum Sulfate: AlSO4

Send your message to us

Mill Finish Aluminum Coil for Subwoofer Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords