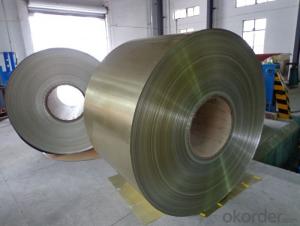

Copper Colored Mill Finished and Color Coated Aluminum Coil for Display Platforms

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finished And Color Coated Aluminium Coil For Display Platforms

Description

Alloy | 1060, 1100, 3003, 8011, etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.05mm to 3.0mm |

Width | Standard width:1240mm |

Special width:1300mm, 1520mm, 1570mm, 1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, ACRYLIC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness(pencil resistance) | More than 2h |

Coating adhesion | 5J (EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend) | 2T |

MEK resistance | More than 100 |

Advantage | 1.High temperature resistant 2.Weathering resistant 3.Scrubbing resistant 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

Out package | Wooden splint with export standard |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels, etc |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: What are the thickness tolerances for aluminum coils?

- The thickness tolerances for aluminum coils can vary depending on the specific grade and alloy of aluminum being used. Generally, the tolerance range for aluminum coil thickness is within +/- 0.003 to 0.015 inches (0.076 to 0.381 mm). However, it is important to note that different industries and applications may have their own specific requirements and tolerances. It is recommended to consult the relevant industry standards or specifications to determine the precise thickness tolerances needed for a particular application.

- Q: Can aluminum coils be used in the production of window frames?

- Yes, aluminum coils can be used in the production of window frames. Aluminum is a lightweight and durable material that is commonly used in the construction industry for its corrosion resistance and strength. By using aluminum coils, manufacturers can efficiently produce window frames that are long-lasting, energy-efficient, and aesthetically pleasing.

- Q: Are there any limitations or restrictions on the use of aluminum coils?

- Yes, there are limitations and restrictions on the use of aluminum coils. Some of the limitations include the maximum operating temperature, which is typically lower compared to other metals, such as copper. Aluminum coils may also have lower electrical conductivity, making them unsuitable for certain applications that require high conductivity. Additionally, the corrosion resistance of aluminum coils can be compromised in certain environments, necessitating protective coatings or alternative materials. Lastly, the strength and durability of aluminum coils may be lower compared to other materials, which may limit their use in certain high-stress applications.

- Q: What are the common packaging options for aluminum coils?

- Common packaging options for aluminum coils include the use of wooden pallets, steel or aluminum cradles, and cardboard or plastic wrapping. These packaging options are designed to provide protection and ensure the safe transportation and storage of the coils. Wooden pallets are commonly used as a base for stacking the coils, providing stability and ease of handling. Steel or aluminum cradles are often used to hold the coils in place, preventing movement and potential damage during transit. Additionally, the coils may be wrapped in cardboard or plastic to offer an extra layer of protection against moisture and other environmental factors. These packaging options are frequently used in the aluminum industry to preserve the quality and integrity of the coils until they reach their destination.

- Q: how many chloride ions are present? how many chlorine ions are present? what is the mass in grams of one formula unit of aluminum chloride?

- Aluminum Chloride is simply AlCl3 So In each mole of AlCl3 there are 1 mol of Al 3 mol of Cl We know (from periodic table), 1 mol of Al weighs 26.98 g 1 mol of Cl weighs 35.47g so 1 mol of AlCl3 weighs 26.98g + 3x35.47g = 133.39 g sooo moles of AlCl3 = 37.2 g /133.39 g/mol = 0.279 mol in one mol of anything, there are 6.02 x 10 ^ 23 of that thing... so we have 0.279 mol x 6.02 x 10 ^ 23 molecules /mole = 1.68 x 10 ^ 23 And, we know one molecule of AlCl3 dissociates into one Al ion and 3 Cl ions sooo 1.68 x 10 ^ 23 AlCl3 ions dissociate into 1.68 x 10 ^ 23 Al ions so answer is 1.68 x 10 ^ 23 Al ions

- Q: What is the typical elongation of aluminum coils?

- The typical elongation of aluminum coils can vary depending on several factors, such as the specific alloy and temper of the aluminum, the manufacturing process, and the intended application. However, aluminum coils generally exhibit a high elongation capability. On average, aluminum coils can have an elongation of around 5-15%, which means they can stretch or deform by this percentage without fracturing or breaking. This property is a result of the inherent ductility of aluminum, which allows it to be easily formed and shaped without losing its structural integrity. The elongation of aluminum coils plays a significant role in various industries, such as construction, automotive, and aerospace, where the material is commonly used. It allows for efficient fabrication processes, such as bending, rolling, and stamping, to create complex and precise shapes. It is important to note that the elongation of aluminum coils can be further improved through specific alloying elements and heat treatments. These processes can enhance the material's properties, making it even more suitable for demanding applications that require superior strength, ductility, and elongation capabilities. In conclusion, while the typical elongation of aluminum coils ranges from 5-15%, it is crucial to consider the specific alloy, temper, and manufacturing processes to accurately determine the elongation properties for a particular application.

- Q: I did a activity series lab and on my data table, it shows that lead reacted more than aluminum did, but aluminum is more active than lead. So, why does it show that lead is more active when it really isn't? Is it human error?

- Aluminum is more active than lead. You should double check your activity data table. If you confirm that the table says that lead is more active than aluminum, the table is in error.

- Q: How are aluminum coils processed for specific applications?

- Aluminum coils are tailored for specific applications through a series of processes. The first step involves selecting a high-quality aluminum alloy, which determines the properties of the coil. Once the alloy is chosen, it is melted and cast into large ingots. After cooling, heavy rollers are used to reduce the thickness of the ingots and form long, continuous aluminum coils. Following this, the coils undergo various surface treatments to improve their performance and appearance. One common treatment is cleaning, which eliminates any impurities or contaminants from the coil's surface. This is typically achieved through chemical or mechanical means. Another treatment involves chemically etching the surface to create a specific texture or pattern, which can enhance adhesion or aesthetics. To further enhance the coil's properties, it may undergo processes such as heat treatment or annealing. Heat treatment involves heating the coil to a specific temperature and then rapidly cooling it to modify its mechanical or physical properties. On the other hand, annealing involves heating the coil to a predetermined temperature and slowly cooling it to relieve internal stresses and improve ductility. Coils intended for specific applications may also undergo additional processes. For example, if the coil is destined for use in the automotive industry, it may undergo lubrication or coating processes to reduce friction or enhance corrosion resistance. If it is meant for electrical applications, it might undergo surface treatments to improve conductivity or insulation properties. Finally, the coils are typically cut into desired lengths and packaged for transportation. This can be done using various methods such as slitting, shearing, or sawing, depending on the application and customer requirements. In summary, the processing of aluminum coils for specific applications involves a combination of casting, rolling, surface treatment, heat treatment, and additional processes to enhance their performance, appearance, and suitability for their intended use.

- Q: What are the common industry standards for aluminum coil specifications?

- The common industry standards for aluminum coil specifications include the Aluminum Association (AA) standards, ASTM International specifications, and the European Standards (EN) for aluminum coils. These standards typically cover dimensions, tolerances, mechanical properties, chemical composition, surface finish, and other technical requirements for aluminum coils used in various industries such as construction, automotive, aerospace, and electrical. Compliance with these standards ensures consistent quality and compatibility with industry applications.

- Q: Can aluminum coils be custom-made to specific requirements?

- Yes, aluminum coils can be custom-made to specific requirements. Aluminum coils are versatile and can be tailored to meet a wide range of specifications and applications. Manufacturers can customize the dimensions, thickness, width, and length of the coil to accommodate specific requirements. Additionally, various surface finishes, such as embossed patterns or coatings, can be applied to enhance the appearance or improve functionality. Customization of aluminum coils allows for precise matching of specific needs in industries such as construction, transportation, aerospace, and many others.

Send your message to us

Copper Colored Mill Finished and Color Coated Aluminum Coil for Display Platforms

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords