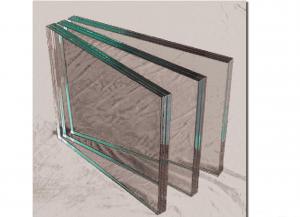

Milky Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 20ft FCL m²

- Supply Capability:

- 1200 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) good safety function

2) high anti-impact intensity

3) unique anti-theft function

4) keep pravicy

5) modern

Laminated glass, is a kind of security compound glass made by sealing two or more pieces of glass together with PVB film through the process of heating and pressurization. The shape of the glass can be flat or curved.The laminated glass has 2 layers,3 layers,5 layers, 7 layers, or more.

Function and Characteristic of Milky Laminated Glass:

1. Good safety function, because of the agglutinated function of the PVB film, when the glass is broken, only bring into radiation-like crackle, the fragment will not scatter out. It is safe and can not hurt people. So, it is widely used in the windshield glass for automobiles.

2. Gigh anti-impact intensity. When it is striked, the glass is not easily broken. Its anti-impact intensity is much better than common glass.

3. Unique anti-theft function. The glass is not easily broken and enters, so it is very safe.

Dimension of Milky Laminated Glass:

Max: 2440mm*3500mm

Min: 300mm*300mm

Application:Curtain wall, partitions, stair-steps, handrails,railings, fences, awnings, etc.

- Q: Which glass factory has good glass?

- Fireproof glass, bullet proof glass, gold mirror, Chajing, black mirror, mirror gray, blue mirror... Is the original piece of glass processing, if the original piece of glass (raw material) of the old good to see the unit of processing technology.

- Q: Water glass, ceramics, ordinary cement, quartz glass, what are these chemicals?

- Water glass chemical formula is Na2SiO3.9H2O, usually quartz and caustic soda (NaOH) wet production, or with quartz and soda ash (Na2CO3) dry production, both need high temperature.

- Q: What is glass made of?

- According to the designed material sheet, the raw materials are weighed and mixed evenly in a mixer. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.

- Q: Tile selection, paving process

- The base should be clean, irregularities to chisel and repair, base should be clean, not a mortar, especially lime mortar, oil, and water wet ground.When laying stone or ceramic tile, standard blocks shall be placed. Standard blocks shall be placed at the intersection of cross lines and diagonally installed.Paving operation to each line in line, the stone must be soaking wet, dry wipe back.

- Q: What are the ingredients of photovoltaic solar glass? What's the function of each?

- The first is silica, which is mainly plays a role of the body to form a network, so the amount of the majority of glass components in a large amount; second is the soda, is mainly sodium oxide, can reduce the glass melting temperature;

- Q: Is the raw material of organic glass harmful to human body?

- Organic glass is a popular name. From this name you may not know what kind of material it is, nor can you tell what element it is made of.

- Q: Who can tell me the raw material and function of the flashy glass?

- Float and other molding methods, its advantages are: suitable for efficient manufacturing quality of flat glass, such as no wave, uniform thickness, smooth surface, upper and lower are parallel to each other; the scale of the production line is not affected by the forming method, energy consumption per unit of product is low; the finished high utilization rate; easy to scientific management and implementation across the board mechanization, automation, high labor productivity; continuous operation cycle of up to several years, is conducive to stable production; to provide suitable conditions for the on-line production of some new varieties, such as electric float reflective glass, annealing, cold end spraying film glass surface treatment etc..

- Q: Could you tell me that three yuan ethylene propylene (EPDM) rubber can resist ethylene glycol?

- Three yuan ethylene propylene is ethylene, propylene and non conjugated diene three copolymer. Diene has a special structure, only one of the two keys to copolymerization, unsaturated double bond, mainly as the chain. Another unsaturated polymer will not become the main chain and will only become side chains. The main polymer chain of three yuan ethylene propylene is completely saturated. This property allows three yuan ethylene propylene to resist heat, light, oxygen, especially ozone. Three yuan propylene is essentially non-polar, resistant to polar solutions and chemicals, low water absorption, and good insulation properties.

- Q: What material is used in the protective film in the middle of glass?

- The raw material glass membrane used in general is Japan's Asahi pin and domestic luoyang,

- Q: Why is the process of glass toughened always broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

1. Manufacturer Overview

| Location | Zhejiang,China (Mainland) |

| Year Established | 1999 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Northern Europe |

| Company Certifications | TUV(GMC-GLOBAL MANUFACTURER CERTIFICATE); GB/T20041-2004 IDT ISO14001:2004; GB/TI9001-2008 IDT ISO9001:2008; GB/T28001-2001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,Ningbo |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Milky Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 20ft FCL m²

- Supply Capability:

- 1200 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords