Laminated Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

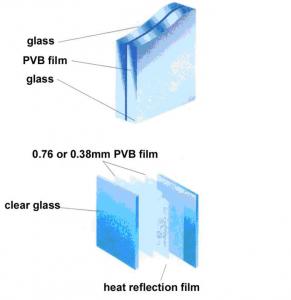

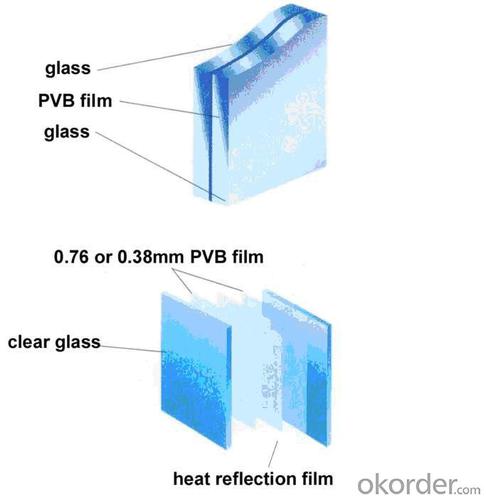

Laminated Glass is made of high quality float glass, coated glass of various colors, Low-E glass, tempered glass, thermo-strengthening glass and bent/tempered glass. It is a product integrated with two or more glass sheets and one or more layers of organic polymers like PVB, EVA, SGP, etc. It is processed by the tablet machine under high pressure and high temperature, making it unite into one lastingly.

Features:

1. Safety glass

2. Fine light control and heat insulation when using coated glass

3. Sound insulation and noise reduction

4. Good structural feature

5. In order to guarantee the quality of laminated glass, the PVB films are imported from Dupont of the USA or Sekisui of Japan.

6. The colors of the films include clear, milk, blue, dark grey, light green, bronze, etc.

Specifications:

Thickness of Glass: 3mm; 4mm; 5mm; 6mm; 8mm; 10mm; 12mm

Thickness of PVB film: 0.38-3.04mm

Size:

300*300mm

3000*8000mm

customized size

Applications:

Laminated Glass is applied in curtain walls, hotels, banks, airports, sunshades, lighting roofs, windows and gates, sprung roofs, indoor glass partitions, glass furniture, show windows, bars, jewelry shops, elevators and so on.

- Q: Chemical materials and additives needed for the production of glass

- 1. Blending of raw materials. The main ingredients of float glass are: 73% of silica, 13% of sodium carbonate, 9% of calcium oxide and 4% of magnesium. The ingredients are mixed in proportion, followed by the addition of small pieces of recycled glass.2. Melting of raw materials. The prepared material passes through a mixing bin and then goes into a kiln with 5 chambers and is heated at about 1550 degrees centigrade to become a molten glass. 3. Glass forming. Molten glass flows into a tin bath and floats over molten molten tin, at a temperature of about 1000 degrees celsius. The molten glass on the tin solution forms a glass band of 3.66 meters wide and a thickness of 3mm to 19mm. Because the glass and the tin are very different in viscosity, the molten glass at the top does not mix with the molten tin below, and forms very smooth contact surfaces.4. Cooling of molten glass. When the glass band leaves the bath, the temperature is about 600 degrees Celsius, then it enters the annealing chamber or the continuous cooling kiln, and the temperature of the glass is gradually reduced to 50 degrees celsius. Thus, the glass produced by the Xu cooling method is also called annealed glass. 5, cutting and storage. After the cold, the glass passes through several stages of quality inspection, then cut into different sizes for packaging, storage, storage or transportation.Quartz sand is a hard, abrasion resistant and stable chemical silicate mineral. Its main mineral composition is SiO2, the color of quartz sandFor the white, colorless or translucent, 7 hardness, brittle cleavage, conchatus fracture, oil sheen, density 2.65, bulk density (1-2.0 = 1.6), 20-200 was 1.5, the chemical, thermal and mechanical properties have obvious anisotropy, insoluble in acid, slightly soluble in KOH solution, the melting point of 1750 DEG C.

- Q: How is the glass made?

- Glass cup making process:1: silk;2: blow the ball;3: skin opening;4: inner opening and back cover;5: interface;6: back cover;7: affixed trademarks;8: annealing.Glass (glass) is the raw material is a glass of glass, usually raw material is high borosilicate glass, after more than 600 degrees of high temperature firing, it is a new type of environmentally friendly tea cup, more and more people's favor.

- Q: What is the raw material of glass products?

- Ordinary glass is the raw material of soda (sodium carbonate), limestone (calcium carbonate) and silica by high temperature reaction, with sodium silicate, calcium silicate and silica products, according to the needs of different substances will add color.For example, adding chromium oxide (Cr2O3) glass, is green; adding manganese dioxide (MnO2), purple glass; adding cobalt oxide (Co2O3) glass, blue glass, copper, copper oxide is high if the glass appeared blue and green; in order to lower the price of cuprous oxide (Cu2O) when there is red glass.Now, people use the oxide of rare earth elements as coloring agents to make all kinds of high-grade color glass. Colored glass doped with rare earth elements has a bright, bright color and even changes colors in different light. For example, in the glass of neodymium oxide has this characteristic, it shows purple red in the sunlight, in the fluorescence of purple blue, very beautiful. There is a kind of glass that changes with the intensity of light. People use it as the lens of glasses and the window glass of the house. With this kind of glass as a window, the room can maintain a certain brightness, and no longer need to use curtains to shade, so some people call it "automatic curtain"". It can prevent the UV rays of the sun through the library and Museum Library, installed on the glass, can protect the books and cultural relics from UV damage, in addition to the rare earths, directly adding tungsten and platinum in the glass, can also be made of glass.

- Q: The difference between crystal glass and glass

- Feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be. Ordinary glass weight is more self-evident.

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- With the progress of science development, composition and characteristics of glass and glass gradually get more understanding, research and development and production scale also has a good improvement, people can use a variety of silica sand quality production of a variety of uses a glass. Manufacture of optical glass, silica sand with high quality special glass, crystal glass, with medium quality silica sand production of flat glass, can also be used for sand production of colored glass, and according to the national defense and economic construction, research and development, production of various types of special glass

- Q: Tile selection, paving process

- Clean up the grass ground, cement mortar, fixed elevation, elastic line, sheet materials choosing, soaking wet, standard for the installation of block, paving cement mortar, paving stone, pouring and cleaning, maintenance and commissioning.

- Q: Why a broken glass film

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: What's the difference between crystal and ordinary glass?

- Feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be. Ordinary glass weight is more self-evident.

- Q: What is the raw material of glass?.

- Glass material is complex, but can be divided into main raw materials and auxiliary raw materials according to its function. The main material constitutes the main body of the glass, and determines the main physical and chemical properties of the glass. The auxiliary material endows the glass with special properties and facilitates the manufacturing process.

- Q: Use of glass flake cement

- Coatings containing glass flakes are much harder than epoxy or polyester resin without glass flakes, and therefore have higher surface abrasion resistance.

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1993 |

| Annual Output Value | US$ 10 Million - US$ 50 Million |

| Main Markets | North America; Europe; Australia; Japan; South East Asia; Middle East; Hong Kong; Macao |

| Company Certifications | ISO 9001:2000;ISO14001:2004;OHSAS 18001 system;3C safety Certificate;SGCC (USA);CE (EU);UL (USA) |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Laminated Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords