VIP Microporous Insulation Panels for Cement Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

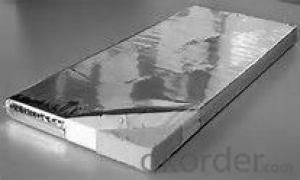

Quick Details for Microporous Insulation Panel as Insulation Materials for Cement Industry

| Place of Origin: | China (Mainland) | Brand Name:CMAX | micropores insulation board | Model Number: | micropores insulation board |

| Material: | PTFE | Thickness: | 3mm-100mm, 3mm-100mm | Size: | Length & Width: 500mm*500mm,600mm*600mm,1000mm*1000mm,1200mm*1200mm |

| Certificate: | ISO9001:2000,ISO9001:2008 | Type: | Molded sheet | Length & Width: | 500mm*500mm,600mm*600mm,1000mm*1000mm,1200mm*1200mm |

| Grade: | A grade (100% virgin), B grade (50% virgin), C grade ( 30% virgin) | Polytetrafluoroethylene: | PTFE,also named TEFLON. | Characteristics: | includes molded sheet and skived sheet |

| Applications: | used within -180℃~+260℃ | Delivery: | 7 days after the receipt of the deposit | Packaging: | Pallet or according to customer requirement |

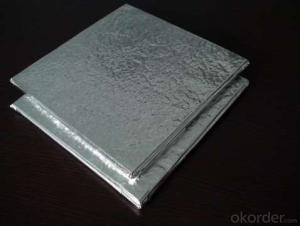

Packaging & Delivery

| Packaging Details: | 1.Wrapped in plastic film to prevent moisture, put into cartoons strapped by polyethylene. Specification marked on the lateral package. 2.Twined with plastic film on the tray after heat shrinkage. |

| Delivery Detail: | 7-15 days |

Size and dimensional tolerances:

Length (±3mm) | Width (±2mm) | Thickness (+3,−1.5mm) |

2000 | 600,500 | 25—120 |

1260 | 1230,610 | 25—120 |

610 | 400,300,150 | 25—140 |

600 | 300 | 25—140 |

524 | 400 | 25—140 |

500 | 500 | 25—140 |

400 | 250 | 25—140 |

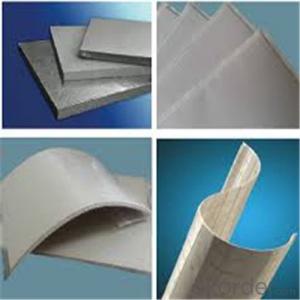

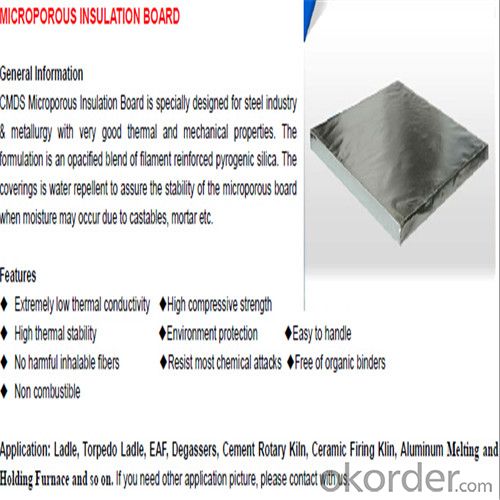

2.Specifications/Microporous Insulation Panel as Insulation Materials for Cement Industry

The highest heat resistance temperature is up to 1100 degree centigrade,the maximum flexural strength is up to 0.7MPa.

1).good durability and can withstand high-temperature limit of the continuous thermal load

2).low thermal conductivity,in the whole scope of use is unmatched within the adiabatic Performance

3).light weight,high stength,its strength is rigid insulation products in the highest

4).durability,long-term use of ceramic fiber felt no similar powder

5).construction practical,with ordinary tools can be arbitrarily cutting products

6).used safety,hygiene,asbestos-free,sulfur,chlorine such poisonous substances

7).fear water,but after drying also can be used

Good durability,and can withstand high-temperature limit of the contimuous thermal load

We obtained CE,KR and ISO9001

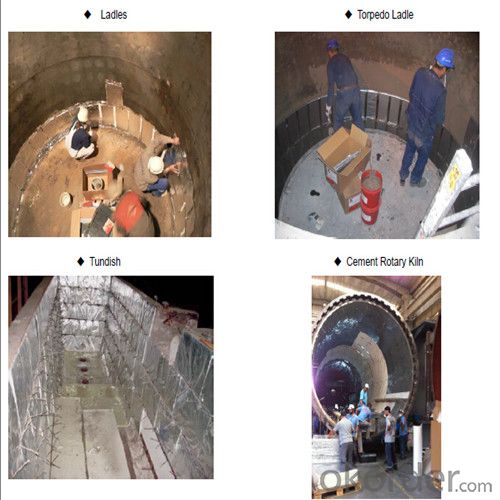

3. Applications of micropores insulation board

Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, Bestin boards are also applicable to places where high security is needed. PTFE Sheet can be used within -180°C~+260°C and working in all sorts of corrosive medium

for sealing member,bearing strip,electrical insulation parts and lubricant etc.

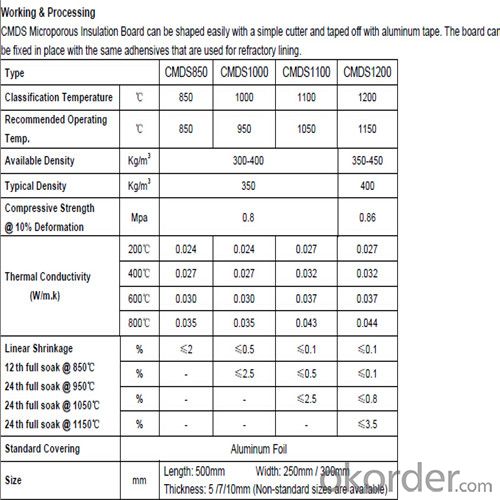

4. Technical of micropores insulation board

Our Service

1) High performance cost ratio with steady quality

2) OEM service and Prompt Delivery

3) The fast speed of reply your email and can make quotation sheet just for you.

4) Can provide free sample, only need you bear the sample fee.

5) Supply good after-sales service, we will follow-up the situation after using, if have problems,we will find out the

reason and deal with positively.

Let's give each other an opportunity!!!

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- The traditional ceiling color steel tile composite composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K) above), plus There is a gap between the foam board and the board, the temperature is very serious, the comprehensive thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because in the construction of the use of direct spray molding technology, so that the polyurethane foam layer is not the overall burden of sewing the body to form a complete impermeability, fundamentally put an end to the possible deep Sex. Which play a preservative effect.

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- This place is different in different places, the calculation is not the same. We are here so: independent columns need to calculate the scaffolding to (peripheral circumference +3.6) multiplied by the column height calculation, 3.6 meters below the single row of scaffolding, 3.6 meters above the corresponding height of the double row. With the overall beam of the beam does not calculate the scaffolding. You say the frame column, to distinguish between different situations.

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- What do you mean if you want to get your own steel pipe fastener? Which city is in the city?

- Q: What is the best insulation material? To be waterproof.

- Under normal circumstances, the steel structure of the plant panel can be a single laminated steel plate, double laminated steel plate, composite color plate. Single-layer steel plate used for simple plant or temporary plant roof, this material is affordable, but the insulation effect is poor, easy to leak. Double laminated steel plate effect will be better. Composite color steel plate for the use of insulation materials sandwich practice, insulation and noise effects are very good, but as a roof, the national standard requires sandwich material must be flame retardant or non-combustible materials.

- Q: External wall insulation material which is good, external wall insulation materials

- Advertisement is here! In fact, the so-called fresh air ventilator is a conceptual product. Ventilation function is very limited, that is difficult to achieve the effect of exchange air. As to say that the answer is more efficient and nonsense. Said the ventilation is limited, because of its small import and export, the amount of ventilation at the end. At the same time the indoor outlet can not guarantee the dirty air away. Said the heat exchange, you can imagine, indoor and outdoor air temperature difference will be more than ten degrees only in a small exchange area and a very short exchange time, in order to replace the hot air into the indoor temperature near the cold air , There is no material to do now.

Send your message to us

VIP Microporous Insulation Panels for Cement Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords