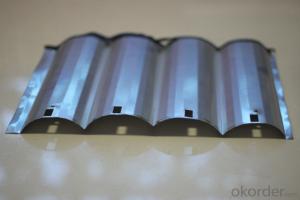

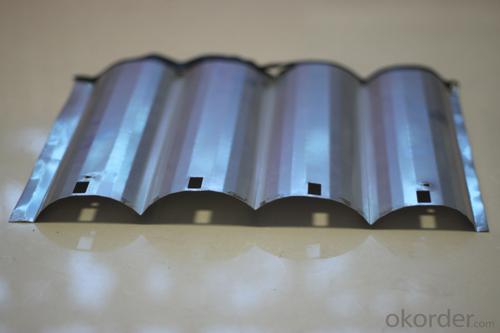

METAL ROOF FOR WAREHOUSE TOP IN PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

By introducing an automated continuous large production line of fireproof modified phenolic insulation board,applying modified phenolic foam and conducting technical improvement,

The board passed the tests by China Building Material Test Center on Jul. 20, 2011, complying with the national requirements with regard to burning performance and other indicators: its burning performance meets the requirements of grade-A composite (laminated) material specified in GB8624-1997 Standard;its volume density, compressive strength, flexural strength, compression creep, size stability, coefficient of heat conductivity, coefficient of moisture permeability and volume water absorption all conform to the requirements of grade-A type II product specified in GB/T 20974-2007 Standard.

The board is applicable to:

(1)Building walls, roof insulation and the insulation layer of composite boards;

(2)The fire barrier zone of the insulation system for traditional EPS/XPS/PU exterior walls;

(3)Fireproof insulation within curtain walls, insulation for fireproof doors and fireproof insulation in low-temperature or high-temperature conditions.

- Q: How to install the cold sandwich sandwich sandwich panels

- If the use of polyurethane cold storage board, then use the structure of the installation of the installation time can be reported to us can also install their own This is a drawing in accordance with the drawings can be installed

- Q: Sandwich panel sandwich panel characteristics

- 1, the quality of light per square meter weight less than 24kg, can fully reduce the structural cost. 2, the installation of fast and light weight, plug, install and can cut the characteristics of arbitrary, to determine the installation of simple, can improve efficiency and save time. 3, fire, color steel composite plus core board of the surface material and insulation materials for non-burning or flame retardant materials, to meet the fire safety requirements. 4, fire-resistant, with a special coating of colored steel sheet up to 10-15 years, after every ten years spraying anti-corrosion coating, sheet life of 35 years 5, beautiful, pressure plate clear lines up to dozens of colors, with any style of the building needs 6, thermal insulation commonly used insulation materials are: rock wool, glass fiber cotton, polystyrene, polyurethane, low thermal conductivity, with a good thermal insulation effect. 7, environmental protection, noise, composite board noise intensity up to 40-50 dB, is a very effective sound insulation material. 8, plastic flexible steel plate can be arbitrarily cut, enough to meet the needs of special design. 9, high-strength high-strength steel plate as the substrate, tensile strength of 5600 (kg / cm2), coupled with the most advanced design and roll forming, with excellent structural characteristics

- Q: Can polyurethane sandwich panels be used for cold storage?

- Polyurethane sandwich panels can be used to make cold storage, polyurethane sandwich panels are two-component liquid polyurethane AB material through the prefabricated production line. Polyurethane sandwich board in the polyurethane material is isocyanate and polyether as the main raw material, in the foaming agent, catalyst, flame retardants and other additives under the action of foam polymer. Polyurethane rigid foam is a new type of synthetic material with insulation and waterproof function, its thermal conductivity is low, only 0.022 ~ 0.024W / (m · Κ), equivalent to half of the extruded plate, is the thermal conductivity of all insulation materials lowest. Cold storage polyurethane insulation generally have two kinds of technology, one is the use of sandwich panel on-site stitching, and another process is the use of polyurethane spray coating on-site spraying foam, compared to the first process, the second process because it is on-site spraying foam Any seams, greatly avoid the phenomenon of hot and cold joints, insulation effect is better than the first process.

- Q: Solid wood sandwich board how much money a piece

- No-name card (no license) 50 ~ ~ 60 yuan a brand, but the quality of the general 70 ~ ~ 90 yuan a brand, brand products (real 3A) more than 120 yuan each! Hope to help you, please adopt

- Q: Build a color steel sandwich panel production plant how much money

- The general machine price of 25 million or so, the venue costs plus how much raw materials you need, you can run the general about 100 million, but the funds to return to the fast, can not have too much debt.

- Q: I just got a polyurethane sandwich board production line, I would like to ask about making money!

- Soft surface or color steel? Color steel is now OK, soft surface of many areas do not let the country, B2 is not up to standard, B1 technology is not mature, and now do the wall decoration board quite fire

- Q: Color steel plate, color steel sandwich panels, clean color steel plate is the same thing? How much is the price?

- Color plate is veneer 0.4 mm about 23 yuan sandwich panel is a double color plate in the middle plus benzene plate on the 0.3 0.2 is about 45 yuan purification board is used in pharmaceutical plants, food purification plant hanging shed wall panels clean plate surface smooth The price is also expensive and more critical is what you want to do

- Q: How to calculate the force of the sandwich panel

- Are generally estimated that we are doing this. Do not know how to calculate, but how many people we have to do the number of board

- Q: Foam sandwich board in line with the fire building requirements? There is no regulatory requirements in this area? I was in Jiangsu !! Thank you

- Comparison of Common Composites and Their Comprehensive Performance. ???????????????????????????????? The new composite plate common metal surface sandwich panels, mortar surface steel sandwich panels, steel mesh sandwich panels, composite lightweight sandwich partition board, composite hollow prefabricated partition board, polystyrene foam mortar powder layer The The metal surface sandwich panel includes metal surface polystyrene sandwich panel, metal surface rigid polyurethane sandwich panel, metal surface rock wool (slag cotton) sandwich panel, single layer color steel rock wool sandwich aluminum thin composite board, Metal gypsum sandwich panels, metal gypsum rock wool sandwich panels. The author through the daily supervision of the relevant situation on the performance of the relevant metal surface composite sheet were a comprehensive comparison, see the following table: Through the above comparison can be seen: metal surface composite fire hazard mainly flammable, easy to melt dripping, high smoke, easy to lose the integrity of the metal surface rock wool (slag cotton) sandwich board fire resistance and combustion Performance can be, the insulation performance is acceptable, but the normal use of the firmness is not enough, the impact on the environment; metal gypsum sandwich panel is both fire and solid, but the insulation performance is poor, the price is more expensive; non-combustible hard Polyurethane metal sandwich panels are expensive.

- Q: Color steel sandwich panel can do the widest, can be more than rice

- The effective width of the color steel sandwich panel is based on the shape of the steel plate you choose. The surface of the sandwich panel has a flat plate and a few peaks, such as: 1) The surface is flat so that its effective width can reach 1.16 m The maximum width of the steel plate is 1.2 m due to the sandwich panel edge structure in order to increase the compressive strength to be folded 2 cm) 2) the surface is a wave shape of the steel plate that you should choose the peak size and size to calculate its maximum effective width.

Send your message to us

METAL ROOF FOR WAREHOUSE TOP IN PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords