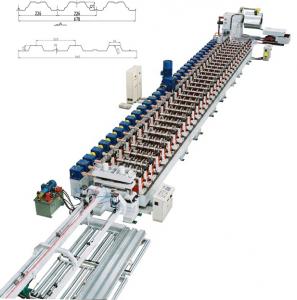

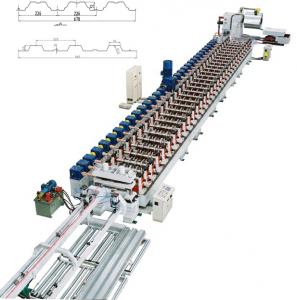

Metal Panel Roll Forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name | Metal Panel Roll Forming Machine | |

Description | This machine is used to roll form the dry wall profiles. | |

Main Parts | ||

(1) | Manual Decoiler | 1 set |

(2) | Guiding Device | 1 set |

(3) | Roll Forming M/C | 1 set |

(4) | Hydraulic Cutting Device | 1 set |

(5) | Run-out Table | 1 set |

(6) | Hydraulic Station | 1 set |

(7) | PLC Control System | 1 set |

(8) | Simple Safety Mesh | 1 set |

Line Speed | About 12 m/min | |

Flow Chart | Coil loading ---- decoiling ---- feeding ---- roll forming ---- cutting ---- run-out | |

Lead Time | 90 - 120 days/set | |

MinOrder | 1 set | |

Package | In bulk | |

Technical data

Main Parameter | ||

(1) | Feeding Width | 240mm(maximum) |

(2) | Rolling Thickness | 0.3 - 0.6mm |

(3) | Rolling Materials | Cold rolled steel coils(Q235) |

(4) | Rolling Speed | About 15 m/min |

(5) | Voltage | 380V/50HZ/Three Phase |

(6) | Number of Rollers | About 16 sets of rollers |

(7) | Material of Roller | GCr15(HRC58-62) |

Reference pictures of Metal Panel Roll Forming Machine:

- Q: What is the roll forming machine?

- The elliptical rolling machine is composed of a rolling device, a rolling pan, a transmission and a brake device, a base, a spindle assembly, a die seat elliptical movement device, a rolling head seat, an electric motor and an electrical control system

- Q: How is the molding machine installed?

- 2 check the main parts of the machine fasteners are loose phenomenon;

- Q: How to maintain the molding machine?

- 3 check the activities of the part, and according to lubrication requirements plus lubricants;

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2001 |

| Annual Output Value | Above US$ 5 Million - US$ 7 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 4-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Metal Panel Roll Forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords