Wall Panel Forming Machine

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 Set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

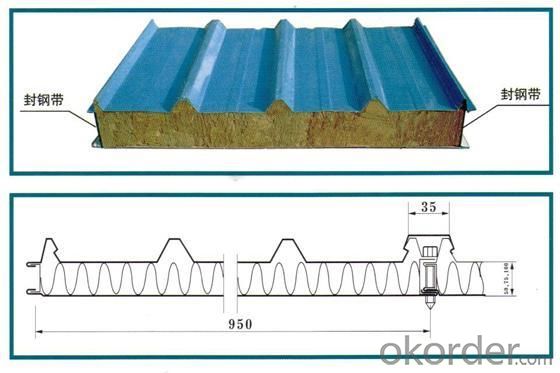

Specifications of Wall Panel Forming Machine

1.CE;ISO9001

2 high strength long life

3.lap convenient light weight

4.high plasticity

Gerenal Information of Wall Panel Forming Machine

This product is widely used in many kinds of industrial factory, civilian buildings, and wall board for attached part product. It has advantage of pretty appearance, durable using and so on.

It is producted continuously as roll forming machine instead using bending machine to make angel tile saving human resources, lower labor cost.

This machine is composed of automatic discharge table, feed leading table, main forming machine, cutting device, hydraulic station and computer control system.

Optional system are normal uncoiler and hydraulic uncoiler.

After roll formed by this machine,the surface will be smooth and beautiful without any scratch on surface.

The Chart of Process flow of Wall Panel Forming Machine

Decoiling→ feeding→ pressing and forming the shape→ measure the length→ cutting→ receiving the plates system—Hydraulic system—

mold pressing machine-Blade-Receiving table

Main forming parameters of Wall Panel Forming Machine

Suitable material | Color steel sheet , galvanized steel sheet, |

Main motor power | 7.5KW |

Hydraulic motor power | 2.2KW |

Hydraulic oil | 36# |

Thickness of material | 0.4mm~0.8mm |

Diameter of principal axis | Φ70mm |

Material expand width | 1000mm |

Electric tension | 380V 3phase 50HZ or as the customer's requirements |

Material of roller | High grade 45# forged steel (plated chrome plating on surface) |

Rolling galvanization thickness | 0.05mm |

Processing speed | 8-12m/min |

Material of cutting blade | Cr12 mould steel with quenched treatment |

Kind of drive | 0.6 inch chain link bearing model 6210 |

Roll Stand | 16 |

Packaging & Delivery of Wall Panel Forming Machine

| Packaging Detail: | Main machine is nude, the computer control box is packed with wooden frame. |

| Delivery Detail: | 20 days |

Application of Wall Panel Forming Machine

- Q: A roll forming machine, rolling out of the length is always not up to a fixed size, not too small, that is, more than that, what is the cause?

- Maybe there is something wrong with that roller. It rolls out of the wrong angle and the size will be out of order.

- Q: What is rolling forming processing?

- A special rolling tool is used to exert certain pressure on the surface of the workpiece so as to make the surface metal flow.

- Q: Improvement in rolling forming process

- It is difficult to control the rolling process and can cause waste easily.

- Q: Introduction of roll forming process

- Not only threaded fasteners industry applications, automobiles, bicycles and other industrial sectors also use rolling forming process, processing complex shapes of parts.

- Q: What kind of material and what heat treatment are used for pressing roller (molding, feeding, cutting force, heavy load, heavy load) of sheet steel rolling machine?

- Use 40Cr or 20Cr, Cr12.Cr12MoV, quenching and tempering treatment, think of hardness, high point, carburizing, nitriding, and consider adding lubrication device to extend its service life

- Q: What is the surface rolling forming machine process?

- Due to the rolling surface of metal plastic deformation, so that the surface microstructure of cold hardening and grain refinement, forming a dense fibrous, and the formation of residual stress, hardness and strength, so as to improve the surface wear resistance, corrosion resistance and compliance.

- Q: Process mould for rolling forming process

- Press forming is an advanced processing technology, and its remarkable characteristics have been paid attention to by the automobile industry at home and abroad.

- Q: Material and equipment for roll forming process

- Rolling process is a cold forging process, which can be used for rolling and forming a lot of materials. Among them, low carbon steel is a material commonly used in rolling forming, and non-ferrous metal is more suitable for roll forming.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2007 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 23.41% Eastern Europe 20.29% Southeast Asia 16.91% Mid East 11.68% Africa 11.00% South America 8.74% North America 4.30% Eastern Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Wall Panel Forming Machine

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 Set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords