Metal Cuplock Ringlock Kwikstage Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Metal Cuplock Ringlock Kwikstage Scaffolding System

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Brand Name:

Surface:

Material.:

Thickness:

Descriptions of Metal Cuplock Ringlock Kwikstage Scaffolding System

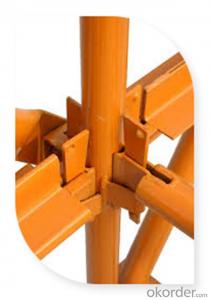

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

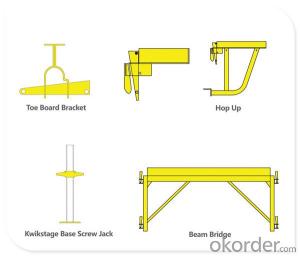

The Accessories of Metal Cuplock Ringlock Kwikstage Scaffolding System

Kwikstage Products: Standard; Ledgers; Transom; Steel Plank; Hop Ups; Diagonal Braces; Tie Bars; Toe board Brackets; End Toe Board Brackets; Double C Clip; External Cup Standard

Props and Formwork: Formwork Prop; Formwork Jacks ; Shoring Jacks

Other Accessories: Ladder Beams; Aluminium Stair ; Base Jack; Swivel Jack ; Steel Pallet; Steel Mesh Pallet.A)Kwikstage Standard

Length: 3.0m;2.5m;2.0m;1.5m;1.0m;0.5m Thickness: 4mm Surface: Painted or Hot Dipped Galvanized Certificate: AS / NZS 1576.3-1995 B) Kwikstage Ledgers

Surface painted or hot dipped galvanized Thickness 3.2mm; 3mm Length 2.4m; 1.8m; 1.2m; 0.7m Certificate AS / NZS 1576.3-1995 C) Kwikstage Transom

Surface painted or hot dipped galvanized Thickness 5mm Length 2.4m;1.8m;1.2m;1.0m;0.7m D)Kwikstage Scaffolding Steel Board / Steel Plank

Length 2.4m ; 1.8m; 1.2m; 0.7m Thickness 1.8mm galv.iron sheet Certificate AS 1577-1993 FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: i need as much detail you can give me on these symbols in the book scarlet letter by Nathaniel Hawthorne. if you have any website references besides cliffs notes and spark notes i would greatly appreciate it!!!

- hey...i'm trying to figure out the same thing....weird.

- Q: Salt doesn't really make any different when cleaning infact I think it makes more dried skin to get stick on the bar. My side piercing is fine but the one closest to my eye is painful when pushed or touched I think this is because I accidentally sleep on it without realising. It's red but it has no lump around the piercing is it infected or is it just trying to heal?

- The reason why the earring will stick to the skin and dry up because you're using too much salt. Cleaning it with warm sea salt water is the best way to clean your piercing, especially soaking it in a bowl for 5-10 min. Make-up wipes have alcohol in them, which irritates piercings, just stick to salt. H2Ocean is great, it's a little pricey but it has the right salinity and other ingredients essential for healing tissues. It's not infected, it's just irritated because you slept on it. An infection will have pain, lots of swelling, dark yellowish pus, and throbbing. Give it a sea salt soak and the redness and soreness will go away.

- Q: Cantilever scaffold technical disclosure

- The surface of the steel pipe shall be straight and smooth, and shall not be used for cracks, scarring, delamination, dislocation, hard bending, burrs, indentation and deep drawing.

- Q: The role of the external scaffolding and the relevant provisions?

- Scaffolding outside the building in the construction of the building is an indispensable important tool for erection. Its role: first, can make the construction personnel in different parts of the operation of the high; two is to ensure the safety of construction personnel in the high altitude operation

- Q: Room 29 meters outside the wall of the two rows of steel pipe scaffolding installation, demolition, joint protection measures in Wuhan, the price per square is how much money? A friend to help refer to Kazakhstan

- When the double row scaffolding longitudinal distance 1.5m, horizontal distance 1.2m, step 1.8m, as per 100 square meters of double row scaffolding rod parts

- Q: Construction, outdoor double scaffolding a square meter how many meters of steel pipe and how much?

- According to the height of their own construction plans, according to the construction area of 1 square root, fasteners ranging from docking fasteners and rotating fasteners, rotating fasteners should be every square of the 3 bar, a detailed look at the old construction workers

- Q: I had my scaffold pierced yesterday and now it is swollen and red. Its throbbing and painful. I have cleaned it and applied ice and antiseptic spray.I don't own any sea salt.HELP ME! I'M SO TEMPTED TO REMOVE IT.

- Antiseptics are too harsh for a healing piercing, the pain, swelling and redness is completely normal. Stop using antiseptic and go to the grocery store to get some non-iodized sea salt, its only a few dollars and you can find it in the spice aisle where the regular salt is.

- Q: The construction scheme of high rise and external cantilever scaffold!

- Cantilever scaffold erection scheme1, the basis of preparation (omitted)2, engineering survey:This project is the building of electricity production, Handan power supply company, located in the main street and Chaoyang Road Interchange, a total construction area of 17747.8m2, the ground layer ten, partial eleven, annex four, underground two floors, the total height of the building is 44 m, frame structure, the project frame adopts double row cantilever beam pick the scaffold in a layer, five layer nine layer is arranged in the cantilever beam. The scaffold scaffold.

- Q: Specification and type of scaffold erection

- Specification for scaffold erection(a) basic requirements1 important scaffolding must develop a construction plan, if necessary, to develop safety assurance measures. 2 more than 25m high scaffolding must adopt the fastener type steel tube scaffold, the single pole scaffolding height should be controlled within 50m; height of more than 50m of the scaffolding should be effective measures by a double pole, wire rope, cable stayed unloading segment, and additional design.3 the design of the scaffold shall meet the requirements of the project and shall indicate its use, maximum static load, maximum dynamic load andThe selected design parameters and structural parts shall not be lower than the existing national and industry related safety technical standards.4 scaffolding in the construction of the need to change the original structure, Gago (wide), to its use, etc., must be verified by the technical department, and the approval.

- Q: How does the second scaffold scene morally change Hester Prynne?

- concentration your activity on who's on the scaffold, how they react to the customary public shaming, and what the reader learns with connection with the character from analyzing the define of them on the scaffold.

Send your message to us

Metal Cuplock Ringlock Kwikstage Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords