Aluminum Corner Strips Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1)Aluminum have been the primary material of choice for structural components of aircraft since about 1930.

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

(1)Aerospace alloys

(2)Scandium–aluminium

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate Promotional development Frictions

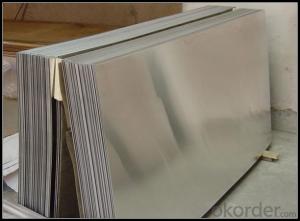

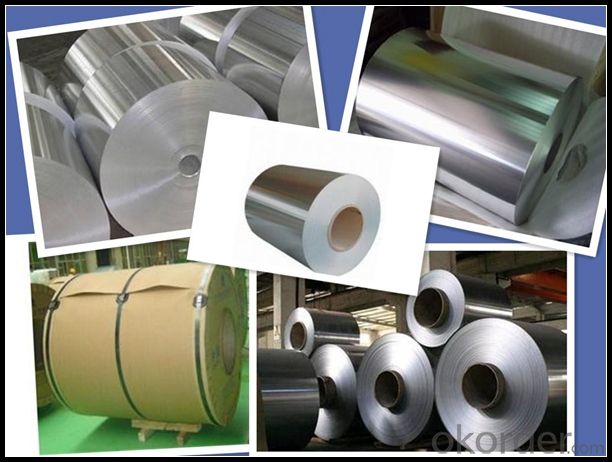

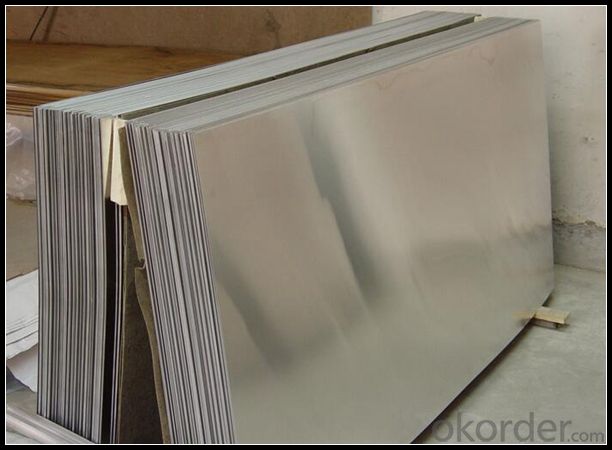

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What characteristics of aluminum strips make them ideal for specific uses?

- <p>Aluminum strips are suitable for certain applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. They are also known for their good thermal and electrical conductivity, making them ideal for heat sinks and electrical components. Additionally, aluminum strips are easily machinable and can be formed into various shapes, which is beneficial for manufacturing. Their non-magnetic properties are advantageous in applications where magnetic interference is a concern. Lastly, aluminum's recyclability and cost-effectiveness make it an environmentally friendly and economical choice for many industrial applications.</p>

- Q: Is it possible to utilize aluminum strips for creating signs or banners?

- <p>Yes, you can use aluminum strips to make signs or banners. Aluminum is lightweight, durable, and resistant to weather, making it a popular choice for outdoor signage. It can be cut, bent, and shaped easily to create various designs. Additionally, aluminum strips can be painted or printed on, allowing for customization with text and graphics. However, ensure that the aluminum is of the appropriate thickness and quality for your specific project to maintain its structural integrity and longevity.</p>

- Q: What benefits does aluminum offer as a roofing material compared to other metals?

- <p>Aluminum strips for metal roofing offer several advantages over other types of metal roofing. They are lightweight and easy to install, reducing labor costs. Aluminum is highly resistant to corrosion, ensuring a long lifespan and low maintenance. It also reflects heat well, which can help keep buildings cooler and reduce energy costs. Additionally, aluminum is recyclable and can be produced in various colors, making it an environmentally friendly and aesthetically versatile choice.</p>

- Q: What specific tools or equipment are necessary to install aluminum strips?

- <p>To install aluminum strips, you generally need a few basic tools. A measuring tape is essential for accurate placement. A utility knife or a metal cutting tool is necessary for cutting the strips to the correct length. A level is crucial to ensure the strips are straight. A rubber mallet or a hammer can be used to secure the strips in place. Adhesive, such as construction adhesive or double-sided tape, is often required to attach the strips. Safety equipment like gloves and safety goggles should be worn to protect against sharp edges and debris.</p>

- Q: What are the benefits of utilizing tailor-made aluminum strips?

- <p>Custom-made aluminum strips offer several advantages, including precise fit and dimensions tailored to specific applications, enhanced durability due to the material's strength and corrosion resistance, and cost-effectiveness as they can be designed to minimize waste. They also allow for unique designs and shapes that standard strips may not offer, providing a competitive edge in industries where aesthetics and functionality are crucial. Additionally, custom aluminum strips can be anodized or coated to meet specific color or finish requirements, enhancing their versatility in various applications.</p>

- Q: How much is the small aluminum belt excavator?

- Now there is kind of about 2 tons in the following, as in 20, 18, 15 models, 10, 08, and small is ultra small, weighs about 1.8 tons from one thousand pounds to have, but also not too light work efficiency, is not suitable for practical use, I want to buy a landscape this year also, see a lot of models. Finally bought 10 Hengyuan excavator, no tail rotating in the empty run does not touch the tree tree, the chassis can be freely telescopic, work is stable, and very flexible, and the electric power, but I don't buy the convenience, diesel engine, price 98 thousand, used now have what to ask the original title, also will not worry so cheap, durable, after the test of practice is also good, over time, ready to buy a.

- Q: What types of aluminum alloys have higher tensile strength compared to others?

- <p>Yes, certain aluminum alloys exhibit superior tensile strength compared to others. For instance, 7075 aluminum alloy, known for its high strength, is often used in aerospace applications. It has a tensile strength of around 524 MPa. Another strong alloy is 2024, which is used in aircraft structures and has a tensile strength of about 425 MPa. These alloys achieve their strength through heat treatment and alloying elements like copper, magnesium, and zinc, which enhance their mechanical properties.</p>

- Q: What types of aluminum strip are best suited for cold climate applications?

- <p>Yes, there are specific types of aluminum strip designed for use in cold climates. These include high-strength aluminum alloys such as 7075 and 6061, which maintain their strength and ductility at low temperatures. Additionally, aluminum strips with a special surface treatment or coating can resist corrosion and maintain performance in cold environments. It's crucial to select aluminum strips with good thermal conductivity and low thermal expansion to prevent warping or breaking in extreme cold. Always consult with material specialists to choose the most suitable aluminum strip for your specific cold climate application.</p>

- Q: Is it possible to use aluminum foil as a material for roofing purposes?

- <p>While aluminum foil itself is not a suitable roofing material due to its lack of durability and structural strength, it can be used as a temporary solution in emergency situations or for small repairs. Aluminum foil is not designed to withstand the elements over time, nor does it provide the necessary insulation or protection against water and wind that a proper roofing material should. For long-term roofing solutions, it's best to use materials specifically designed for roofing, such as asphalt shingles, metal sheets, or tiles, which offer greater durability and weather resistance.</p>

- Q: What are the certifications or standards that apply to aluminum strips?

- <p>Yes, there are several certifications and standards for aluminum strips. These include ASTM B209, which specifies requirements for aluminum and aluminum alloy sheet and plate, and EN 573, which covers the chemical composition and mechanical properties of aluminum and aluminum alloys. Additionally, there are ISO standards such as ISO 6361 and ISO 6892 that define the requirements for aluminum and aluminum alloys in terms of mechanical properties and chemical composition. These standards ensure the quality and consistency of aluminum strips used in various industries.</p>

Send your message to us

Aluminum Corner Strips Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords