Menards Aluminum Coil Stock for Colored Foil Rolls of Hairdressing Aluminium

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 box

- Supply Capability:

- 300000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Description:

Specification :

Status | O |

Alloy Type | 8011 |

Aluminum Content | >99.5% |

Thickness | 9-30 micron |

Length | 9-450m |

Width | 10, 20, 25, 30, 35, 38, 40, 45cm etc. |

l Packaging & Delivery

Packaging detail: Each roll packed with an individual color box or pp bag with printing and shrink package, and with/without blade, then put into Standard export wooden case.or as per customers' requirements. Outer packing: About 4, 6, 12, 20, 24, 48, 60 rolls per carton

Delivery detail: 15-20 days after received deposit

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminum foil is a popular product in CNBM. With advanced technology and equipment, our company has sold large quantities of aluminum foil to the world.

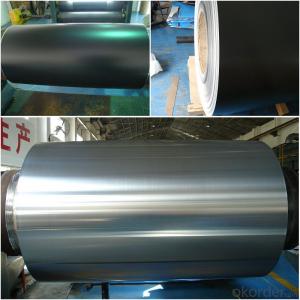

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 20000 boxes

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q: How do aluminum coils contribute to sustainable energy systems?

- Aluminum coils play a crucial role in sustainable energy systems due to several reasons. Firstly, aluminum is a lightweight and highly conductive metal, making it an ideal material for the production of coils used in various renewable energy technologies such as wind turbines, solar panels, and electric vehicles. The lightweight nature of aluminum reduces the overall weight of these systems, thus increasing their efficiency and performance. Secondly, aluminum is abundant in nature and has a high recycling rate. It can be recycled repeatedly without losing its original properties, resulting in significant energy savings and reduced environmental impact. By using aluminum coils, sustainable energy systems can minimize their reliance on virgin materials and promote a circular economy. Furthermore, aluminum coils are corrosion-resistant and have excellent heat transfer properties. This makes them highly durable and capable of withstanding harsh weather conditions, ensuring the longevity and reliability of renewable energy systems. The durability of aluminum coils also reduces the need for frequent maintenance or replacements, thereby minimizing waste generation and conserving resources. Moreover, aluminum is a non-toxic material that poses minimal risks to human health and the environment. Unlike other metals, aluminum does not leach harmful substances into the soil or water, making it a safe choice for sustainable energy systems. Lastly, the use of aluminum coils in sustainable energy systems helps to reduce greenhouse gas emissions. As aluminum is lightweight, it requires less energy to transport and install, thereby reducing the carbon footprint associated with the manufacturing and installation processes. Additionally, the increased efficiency and performance of renewable energy systems using aluminum coils contribute to the displacement of fossil fuel-based energy generation, leading to a reduction in overall carbon emissions. In conclusion, aluminum coils contribute to sustainable energy systems by enhancing the efficiency, durability, recyclability, and environmental friendliness of renewable energy technologies. Their lightweight nature, corrosion resistance, and excellent heat transfer properties make them ideal for various applications, while their abundance and recyclability promote resource conservation and a circular economy. By using aluminum coils, sustainable energy systems can reduce their environmental impact, improve performance, and contribute to a cleaner and more sustainable future.

- Q: Can aluminum coils be fabricated or machined?

- Yes, aluminum coils can be fabricated or machined. They can be cut, shaped, and formed into desired shapes or sizes using various fabrication techniques such as cutting, bending, stamping, or welding. Additionally, machining processes like milling, drilling, or turning can be used to remove excess material and create intricate designs or features on aluminum coils.

- Q: Can aluminum coils be used in automotive heat exchangers?

- Indeed, automotive heat exchangers can utilize aluminum coils. The automotive industry favors aluminum for heat exchangers due to its exceptional thermal conductivity, lightweight quality, and resistance against corrosion. These attributes enable aluminum coils to effectively transfer heat between fluids or gases, rendering them highly suitable for automotive heat exchangers. Furthermore, aluminum coils are easily manufacturable and can be molded into diverse shapes and sizes, thereby further enhancing their appropriateness for automotive applications.

- Q: Is it possible to utilize an angle grinder for cutting hot rolled aluminum coils?

- <p>Yes, you can use an angle grinder to cut hot rolled aluminum coils, but you must take precautions. Use a grinding disc specifically designed for metal cutting, preferably one with a diamond or carbide grit for better performance on aluminum. Ensure the grinder is equipped with a safety guard and wear appropriate safety gear, including goggles and gloves. Be aware that aluminum can be reactive when heated, so cutting may produce sparks and fumes; ensure proper ventilation. Always follow the manufacturer's guidelines for your specific angle grinder and safety regulations.</p>

- Q: why do we use copper more than aluminum? give some characteristic of copper that makes it better then aluminum?

- Copper is greater suitable than aluminum via fact it has a conductivity of ninety seven% whilst in comparison with sixty two % for aluminum.Copper is likewise and safer, via fact, its contacts whilst splicing will stay carrying out even for an prolonged time, mutually as in aluminum, splices especially if carried out copper to aluminum will oxidize after a era, ensuing to overheating and electric powered fires. Aluminum development wiring isn't yet allowed in lots of Asian cities.

- Q: Can aluminum coils be used in automotive suspension systems?

- Automotive suspension systems can utilize aluminum coils. Aluminum, a lightweight and sturdy material, provides numerous advantages for suspension components. Its high strength-to-weight ratio allows it to handle heavy loads without burdening the vehicle with unnecessary weight. This can enhance fuel efficiency and overall performance. Furthermore, aluminum is resistant to corrosion, making it particularly valuable for automotive suspension systems exposed to harsh weather conditions and road debris. By incorporating aluminum coils, manufacturers can ensure that suspension components have a longer lifespan and require less maintenance. In addition, aluminum coils possess superior heat absorption and dissipation capabilities compared to materials like steel. This aids in preventing overheating and mitigating the risk of suspension failure, especially during intense driving conditions or off-road usage. However, it is important to note that the use of aluminum coils in automotive suspension systems may entail certain compromises. Although aluminum is lighter and more resistant to corrosion, it may not be as strong as steel. Therefore, manufacturers must meticulously design and engineer the suspension system to ensure it can withstand necessary loads and provide sufficient support and stability for the vehicle. In summary, aluminum coils can be effectively employed in automotive suspension systems, offering benefits such as lightweight construction, corrosion resistance, and efficient heat dissipation. Nevertheless, manufacturers must carefully consider the specific requirements and trade-offs associated with aluminum usage in suspension components to ensure optimal performance and safety.

- Q: Briefly describe the process of aluminum production from bauxite. Describe the electrolyte and write the anode and cathode half-reactions.

- Bauxite is dissolved in NaOH to remove impurities and form aluminum hydroxide; the aluminum hydroxide is then precipitated out, and water is removed to produce pure aluminum oxide (alumina). In aluminum production, alumina (Al2O3) is dissolved in molten cryolite (Na3AlF6). This molten mixture is then placed in a container with graphite electrodes (cathode and anode are both graphite). The molten mixture serves as the electrolyte. At the cathode: Al3+ (l) + 3e- ---- Al (l) Aluminum ions gather electrons to form aluminum metal, which is liquid due to the high temperatures. The molten metal sinks to the bottom of the container, and is piped off. At the anode: 2O2- (l) --- O2 (g) + 4e- The oxide ions from alumina lose their electrons to form oxygen gas.

- Q: How exactly can you tell (just by looking) that the nipple used to tighten a spoke is brass and not aluminum? I know some are silver - not sure if they are painted silver or what. But without scraping or causing any damage to the nipple, how would one know for sure if they have no experience between the two.p.s. I don't know how heavy or light either is, so if that is one way to tel, it's not a good way for me.

- Commercially pure aluminum has a tensile strength of approximately 90MPa and can be improved to around 180MPa by cold working. Typical Brass alloys have tensile strengths in the range 250 - 500MPa. There maybe different brass materials which exceed this limit. There may be those which are lower in tensile strength than the minimum of this range. Check in the web. But, according to these data, you can see that Brass is stronger than Aluminum. So, the brass plate is stronger than the Al plate. However, Aluminum is a pure metal. Brass is an alloy. So, there maybe different brasses depending on their composition.

- Q: This question asks about the impact of aluminum coils on the quality of food when it is stored. It seeks to understand if there are any changes in the food's properties due to the presence of aluminum coils.

- <p>Aluminum coils themselves do not directly affect the quality of food during storage. They are often used in the packaging industry for their excellent barrier properties against light, oxygen, and moisture, which can help preserve the freshness and quality of food by preventing spoilage and oxidation. However, it's important to note that aluminum does not interact with food in a way that alters its taste or nutritional content. Any potential health concerns related to aluminum exposure are more associated with the manufacturing process and not with the storage of food in aluminum-coiled packaging.</p>

- Q: Is it possible to use aluminum coils in the construction of a solar charger or battery pack?

- <p>While aluminum coils can be used in various electrical applications due to their conductivity, they are not typically used in solar chargers or battery packs. Solar chargers and battery packs usually require materials with higher conductivity and specific properties for efficient energy transfer and storage. Copper is more commonly used for wiring in these devices due to its superior conductivity compared to aluminum. Aluminum may not provide the necessary efficiency and could lead to energy loss. For the best performance in solar chargers and battery packs, it's recommended to use materials specifically designed for these applications, such as high-quality copper wiring and appropriate battery cells.</p>

Send your message to us

Menards Aluminum Coil Stock for Colored Foil Rolls of Hairdressing Aluminium

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 box

- Supply Capability:

- 300000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords