Small Aluminum Coils Factory Directly Wholesale Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

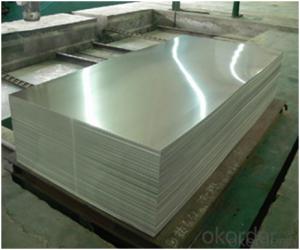

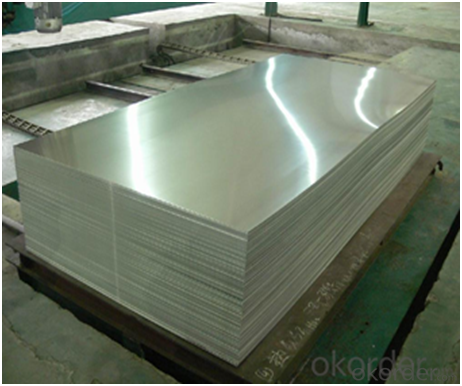

1.Structure of Aluminum Sheets 1xxx C.C Quality Description

Aluminum sheets 1xxx C.C quality is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum sheets 1xxx C.C quality is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets 1xxx C.C Quality

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminum Sheets 1xxx C.C Quality Images

4.Aluminum Sheets 1xxx C.C Quality Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets 1xxx C.C Quality

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the aluminum sheets 1xxx C.C quality products.

B.When will you deliver the products?

The aluminum aluminum sheets 1xxx C.C quality will be delivered within 35 days after receiving advanced payment or original L/C.

C.What is the MOQ?

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be customized to specific requirements?

- Yes, aluminum coils can be customized to specific requirements. The customization process involves adjusting the dimensions, thickness, alloy composition, and surface finish of the coils to meet the specific needs of different industries and applications.

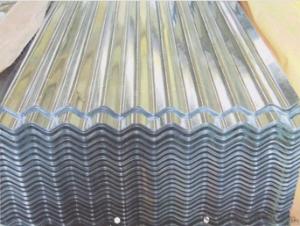

- Q: Can aluminum coils be used for roofing applications?

- Absolutely! Roofing applications can definitely make use of aluminum coils. Aluminum is widely preferred as a roofing material owing to its array of benefits. Its lightweight nature simplifies transportation and installation processes. Additionally, aluminum boasts exceptional durability and resistance against corrosion, guaranteeing an extended lifespan for the roof. Furthermore, it is an ideal choice for regions with high humidity or coastal areas, as it does not succumb to rust. Moreover, aluminum roofing proves to be energy-efficient as it effectively reflects sunlight and heat, thus reducing cooling expenses. All in all, thanks to their robustness, longevity, and energy efficiency, aluminum coils make an outstanding choice for roofing applications.

- Q: What specific tools are required for handling and working with aluminum coils?

- <p>Working with aluminum coil typically requires specialized tools to ensure safety and efficiency. Essential tools include a coil cutter for precise cutting, a coil car for easy transportation, and a decoiler for unrolling the coil. Additionally, protective gloves and safety glasses are crucial for personal protection. For more complex tasks, a shear machine or press brake may be necessary for shaping the aluminum. Always follow safety guidelines and use the appropriate tools for the job to prevent accidents and ensure quality work.</p>

- Q: How do aluminum coils compare to titanium coils in terms of weight?

- In terms of weight, aluminum coils are considerably lighter than titanium coils. This is due to aluminum having a lower density than titanium, resulting in aluminum weighing less than titanium for the same volume. This quality makes aluminum coils highly favored in industries like aerospace and automotive where reducing weight is essential. On the other hand, titanium coils are renowned for their exceptional strength and excellent corrosion resistance, making them ideal for environments that prioritize durability. Ultimately, the decision between aluminum and titanium coils depends on the specific needs and compromises sought for a particular application.

- Q: Are there any recycling programs for used aluminum coils?

- Yes, there are recycling programs available for used aluminum coils. Many recycling centers and scrap yards accept aluminum coils for recycling, as aluminum is a highly recyclable material.

- Q: Can aluminum coils be used for HVAC ducting?

- Indeed, HVAC ducting can utilize aluminum coils. Aluminum, known for its strength, lightweight properties, and resistance to corrosion, is frequently employed in HVAC systems. For the production of HVAC ductwork, aluminum coils are frequently employed as they effectively disperse air throughout the system while preserving its structural stability. Furthermore, aluminum coils exhibit remarkable heat transfer capabilities, enhancing the efficiency of cooling and heating procedures within the HVAC system. All in all, aluminum coils are an appropriate option for HVAC ducting as they offer numerous advantages and fulfill the prerequisites of a properly functioning HVAC system.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Aluminum coils, with their lightweight and durable nature, find application in the creation of aircraft fuel tanks. They are commonly employed in the aerospace industry due to their impressive strength-to-weight ratio. Furthermore, their corrosion-resistant properties make them an ideal choice for fuel tanks, as they can withstand the harsh conditions and chemicals present in aviation fuel. The utilization of aluminum coils enables efficient manufacturing processes, as they can be easily shaped and welded into the desired tank form. Moreover, aluminum possesses excellent thermal conductivity, aiding in the dissipation of heat generated during flight and preventing fuel overheating. In conclusion, aluminum coils are a fitting and extensively utilized material in the production of aircraft fuel tanks.

- Q: I have a 1994 Impala SS with a 5.7L lt1 engine with cast iron heads. Which is better in horsepower gain? Aluminum heads or cast iron heads? People say cast iron heads downsize the hp from 300 to 260 hp. Also which of the two heads are more durable and less restrictive?

- If they are exactly the same with the exception of 1 being aluminum and the other being iron the iron one will make slightly more power. The 2 big differences are you can run higher compression with aluminum and there is a big weight difference.

- Q: This question asks for criteria or methods to determine if a used aluminum coil is safe for reuse.

- <p>To determine if a used aluminum coil is safe to use, consider the following: Check for any visible signs of damage such as cracks, dents, or corrosion. Ensure the coil has been properly cleaned and sanitized to remove any residues or contaminants. Verify that the coil has not exceeded its recommended lifespan or usage limits. Consult the manufacturer's guidelines for any specific safety checks or maintenance requirements. If in doubt, it's best to consult with a professional or replace the coil to avoid potential safety hazards.</p>

- Q: What are the typical dimensions for aluminum coils?

- <p>The standard size of aluminum coils can vary depending on the specific application and industry requirements. Commonly, aluminum coils are available in widths ranging from 600mm to 2000mm and thicknesses from 0.2mm to 6.0mm. The length of the coils can be from 500 meters to over 3000 meters, depending on the weight and the manufacturing process. It's important to note that these dimensions are not fixed and can be customized to meet specific project needs.</p>

Send your message to us

Small Aluminum Coils Factory Directly Wholesale Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords