Melt Extract Stainless Steel Fiber Straight Type China Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Specifications

Produces shear type, steel wire type, cut type, stainless type, and micro wire type steel fiber. It is used for concret.

SPECIFICATION

TYPE | SIZE | tensile strength |

ENDHOOKED STEEL FIBER | 0.5×0.5×30 mm | 850Mpa min |

0.6×0.7×35 mm | 850Mpa min | |

0.5×0.5×30 mm | 1000MPA min | |

0.6×35 mm | 1000MPA min | |

0.9×60 mm | 1000MPA min | |

CORRUGATED STEEL FIBER | 0.25×0.25×10 mm | 380Mpa min |

0.25×0.25×14 mm | 380Mpa min | |

0.5×0.7×32 mm | 380MPA min |

OTHER SPECIFICATIONS CAN BE DISCUSSED AS PER BUYER’S OPTION

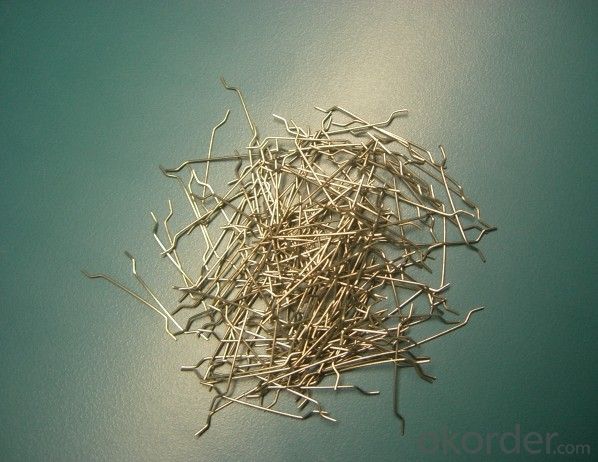

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in swimming pools or water treatment plants?

- Yes, melt extract stainless steel fiber can be used in swimming pools and water treatment plants. It is highly resistant to corrosion and can withstand the harsh conditions associated with water treatment facilities. Additionally, the stainless steel fiber enhances the strength and durability of the concrete used in these structures, making it an ideal choice for such applications.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of plasticity of concrete?

- The effect of melt extract stainless steel fiber on the modulus of plasticity of concrete is that it enhances the overall flexural strength and ductility of the material. When added to the concrete mix, these stainless steel fibers act as reinforcement, strengthening the concrete and increasing its ability to withstand bending forces without fracturing. The presence of these fibers in the concrete matrix helps to distribute the load more evenly, preventing the formation and propagation of cracks. This results in an improved modulus of plasticity, which refers to the material's ability to deform under stress without permanent deformation or failure. By increasing the modulus of plasticity, melt extract stainless steel fibers contribute to a more durable and resilient concrete structure. Furthermore, these fibers also enhance the post-cracking behavior of concrete. Even after the concrete has cracked under load, the stainless steel fibers help to hold the cracked sections together, limiting further crack propagation. This enhances the overall performance of the concrete by increasing its resistance to fatigue and minimizing the potential for sudden failure. In summary, the inclusion of melt extract stainless steel fibers in concrete positively affects the modulus of plasticity by improving flexural strength, ductility, and crack resistance. This leads to a more resilient and durable concrete structure capable of withstanding higher loads, reducing maintenance requirements, and extending the service life of the construction project.

- Q: What are the limitations of using melt extract stainless steel fiber?

- Using melt extract stainless steel fiber comes with several limitations. To begin with, the high cost is a major drawback. Compared to other types of fibers like carbon or glass fibers, melt extract stainless steel fiber is more expensive. This can make it less economically viable for certain applications, especially in industries with tight budget constraints. Secondly, the handling and installation of melt extract stainless steel fibers can be challenging. These fibers are typically very fine and can easily become airborne during mixing or spraying processes. This poses health and safety risks to workers, as inhaling these fibers can cause respiratory issues. To ensure worker safety, special precautions and protective measures must be taken. Additionally, melt extract stainless steel fibers may have limited performance in certain environments. They may not be suitable for applications exposed to high temperatures or corrosive chemicals, as they can lose their strength and durability under such conditions. In these demanding environments, alternative fibers like ceramic or basalt fibers may be more suitable. Furthermore, the effectiveness of melt extract stainless steel fibers in improving concrete's mechanical properties may vary depending on factors like fiber length, aspect ratio, and fiber dispersion. Achieving uniform distribution and alignment of fibers throughout the concrete matrix can be challenging, and this can impact the overall performance and effectiveness of the fiber reinforcement. Lastly, the aesthetic properties of concrete containing melt extract stainless steel fibers may be affected. Since these fibers are metallic, they can alter the appearance and texture of the concrete surface. This may not be desirable for applications where visual appeal is important, such as architectural or decorative concrete. In conclusion, while melt extract stainless steel fibers offer certain advantages in terms of strength and durability improvement, they also have limitations in terms of cost, handling, performance in extreme conditions, fiber dispersion, and aesthetic impact. These factors should be carefully considered when deciding whether to use this type of fiber in a specific application.

- Q: What is the typical dosage of melt extract stainless steel fiber in concrete?

- The typical dosage of melt extract stainless steel fiber in concrete varies depending on the specific application and desired performance. However, a common dosage range is typically between 20 to 40 kilograms per cubic meter of concrete.

- Q: What is the effect of melt extract stainless steel fiber on the impact strength of shotcrete?

- The addition of melt extract stainless steel fiber to shotcrete generally improves its impact strength. This is because the fiber reinforces the shotcrete matrix, enhancing its ability to resist cracking and withstand impact forces.

- Q: What is the recommended fiber dosage when using melt extract stainless steel fiber in shotcrete?

- The recommended fiber dosage when using melt extract stainless steel fiber in shotcrete typically ranges from 25 to 40 kg/m3, depending on the specific requirements of the project and the desired performance characteristics.

- Q: What is the effect of melt extract stainless steel fiber on the carbonation resistance of concrete?

- The use of melt extract stainless steel fiber in concrete has a positive effect on the carbonation resistance of the material. Stainless steel fibers are known for their high corrosion resistance, which helps protect the concrete from carbonation. Carbonation is a process in which carbon dioxide from the atmosphere reacts with the calcium hydroxide in the concrete, forming calcium carbonate. This reaction can lead to a decrease in pH within the concrete, making it more susceptible to corrosion of the reinforcing steel. By incorporating melt extract stainless steel fibers into the concrete mix, the risk of carbonation is significantly reduced. The fibers act as a physical barrier, preventing the penetration of carbon dioxide into the concrete. This helps maintain a higher pH level within the material, protecting the reinforcing steel and enhancing the overall durability of the concrete structure. Additionally, the use of stainless steel fibers improves the mechanical properties of the concrete, such as its tensile strength and flexural strength. This further enhances the resistance of the material to carbonation and other environmental factors. In conclusion, the addition of melt extract stainless steel fibers to concrete significantly improves its carbonation resistance. This leads to increased durability, decreased maintenance requirements, and extended service life of concrete structures.

- Q: Does the addition of melt extract stainless steel fiber affect the curing time of concrete?

- The inclusion of melt extract stainless steel fiber may have an influence on the curing time of concrete. Stainless steel fibers are frequently utilized in concrete to enhance its mechanical properties, such as tensile strength, flexural strength, and resistance to cracking. The introduction of these fibers into the concrete mixture has the potential to decelerate the curing process. This is due to the fact that stainless steel fibers can impede the movement of water within the concrete structure. Water is essential for the hydration reaction that occurs during the curing process, leading to the solidification of the concrete. However, the presence of stainless steel fibers can obstruct the movement of water molecules, thus delaying the hydration process and prolonging the curing time. It is important to consider that the impact on curing time will vary depending on several factors, including the type and quantity of stainless steel fibers added, the design of the concrete mixture, and the environmental conditions during curing. In some instances, the effect on curing time may be insignificant, while in others it can be more substantial. Therefore, when contemplating the incorporation of melt extract stainless steel fiber into concrete, it is crucial to thoroughly evaluate its potential influence on curing time. Seeking advice from concrete experts or conducting laboratory tests can aid in determining the specific effects and optimizing the design of the concrete mixture accordingly.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of shotcrete?

- The effect of melt extract stainless steel fiber on the flexural toughness of shotcrete is an increase in the overall toughness and crack resistance of the material. The stainless steel fibers reinforce the shotcrete, preventing the propagation of cracks and enhancing its ability to withstand bending and flexural stresses. This results in improved durability and structural integrity of the shotcrete, making it more suitable for applications where flexural toughness is important, such as tunnel linings or retaining walls.

- Q: Can melt extract stainless steel fiber be used in high-performance concrete?

- Yes, melt extract stainless steel fiber can be used in high-performance concrete.

Send your message to us

Melt Extract Stainless Steel Fiber Straight Type China Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords