Melt Extract Stainless Steel Fiber - Straight Type CE Approved High Quality Hooked

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Steel fiber types includs,

a) Hooked ends steel fiber

b) Flat head steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Xorex steel fiber

f) Micro-steel fiber

g) stainless steel fiber

Application of Daye steel fiber:

A. Tunnel pre-treatment(primary support)

B. Tunnel forming(permanent lining)

C. Slope stabilization

D. Ditch excavation support

E. Industrial floor

F. Precast concrete element

G. Concrete restoration

H. High performance concrete

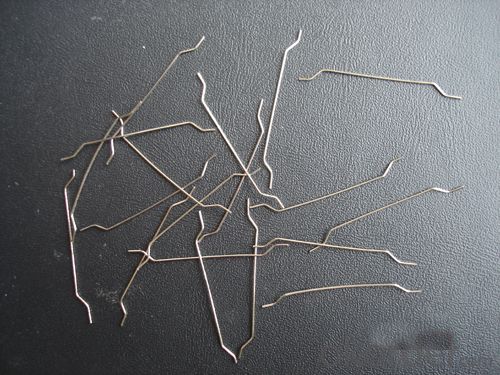

Picture

Steel fiber straight type

Wavy steel fiber

Xorex steel fiber

Micro-steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does melt extract stainless steel fiber affect the crack propagation in concrete?

- Melt extract stainless steel fiber has a significant impact on crack propagation in concrete. When added to the concrete mix, these fibers act as reinforcement and improve the overall mechanical properties of the material. The presence of stainless steel fibers in concrete helps to control the formation and spread of cracks. These fibers are distributed uniformly throughout the concrete matrix, creating a three-dimensional network that inhibits crack growth. The primary mechanism through which stainless steel fibers affect crack propagation is by bridging the cracks that occur during the drying and hardening process of concrete. As the concrete starts to crack under tensile stress, the fibers act as tiny reinforcements that span across the crack faces, effectively transferring the applied load and preventing further crack propagation. This bridging effect enhances the tensile strength of concrete and improves its resistance to cracking. Moreover, the high tensile strength and ductility of stainless steel fibers provide additional benefits in controlling crack propagation. Unlike traditional reinforcement methods such as steel rebars, stainless steel fibers can withstand significant deformation without fracturing. This characteristic enables the fibers to absorb energy and distribute it over a larger area, reducing the concentration of stress around the cracks and minimizing their growth. Furthermore, the corrosion-resistant nature of stainless steel fibers ensures long-term durability and performance. Unlike other types of steel fibers, stainless steel fibers do not corrode in the alkaline environment of concrete, maintaining their effectiveness over time. In summary, the addition of melt extract stainless steel fiber to concrete significantly influences crack propagation by bridging cracks, enhancing tensile strength, absorbing energy, and providing long-term durability. These fibers act as reinforcement, improving the overall performance and longevity of concrete structures.

- Q: How does the addition of melt extract stainless steel fiber impact the shrinkage of concrete?

- The addition of melt extract stainless steel fiber in concrete can help reduce shrinkage. The fibers act as reinforcement, improving the overall tensile strength of the concrete. This reinforcement helps to control the drying shrinkage, preventing cracks and reducing overall shrinkage.

- Q: Can melt extract stainless steel fiber be used in tunnel segment construction?

- Melt extract stainless steel fiber is indeed applicable for tunnel segment construction. It possesses remarkable characteristics such as high tensile strength, corrosion resistance, and durability. These attributes render it suitable for reinforcing concrete in tunnel segments, as they must endure substantial loads and challenging environments commonly encountered in tunnel construction. By incorporating stainless steel fibers into the concrete mixture, its flexural strength can be enhanced, cracking can be mitigated, and overall structural integrity can be improved. Moreover, the melt extract manufacturing process guarantees a consistent dispersion of the fibers and secure bonding with the concrete matrix, thereby augmenting their efficacy in tunnel segment construction.

- Q: What is the typical length and diameter of melt extract stainless steel fiber?

- The size of melt extract stainless steel fiber may vary depending on the specific application and requirements. However, generally speaking, there is a range of lengths and diameters available for melt extract stainless steel fibers. Melt extract stainless steel fiber can have a length ranging from a few millimeters to several centimeters. Shorter fibers are typically used for reinforcing composites, while longer fibers are commonly used for filtration and thermal insulation purposes. The diameter of melt extract stainless steel fiber can also vary, ranging from a few micrometers to a few millimeters. Thinner fibers are often used in applications that require a high surface area to volume ratio, such as conductive textiles or electromagnetic shielding. Thicker fibers, on the other hand, are commonly employed for applications that require greater mechanical strength or thermal conductivity, like reinforcing concrete or heat transfer components. It's important to note that the specific length and diameter of melt extract stainless steel fiber will depend on the desired properties and performance requirements of the application. Manufacturers and suppliers can provide more precise information on the available options and assist in selecting the most suitable fiber dimensions for a particular application.

- Q: Can melt extract stainless steel fiber be used in tunneling and underground construction?

- Yes, melt extract stainless steel fiber can be used in tunneling and underground construction. This type of fiber is commonly used to reinforce concrete and enhance its mechanical properties, making it suitable for various applications in tunneling and underground construction projects. It helps to improve the structural integrity of concrete, increase its resistance to cracking and improve overall durability, making it an ideal choice for these types of projects.

- Q: Can melt extract stainless steel fiber reduce the risk of early-age cracking in concrete?

- Yes, melt extract stainless steel fiber can reduce the risk of early-age cracking in concrete.

- Q: Can melt extract stainless steel fiber be used in lightweight concrete applications?

- Yes, melt extract stainless steel fiber can be used in lightweight concrete applications. Stainless steel fibers are often added to concrete to improve its strength, durability, and resistance to cracking. These fibers can help distribute stress more evenly throughout the concrete, preventing the formation of large cracks. In lightweight concrete, which is made by replacing some or all of the traditional aggregates with lightweight materials, stainless steel fibers can still be incorporated to enhance the overall performance of the concrete. However, it is important to carefully consider the dosage and length of the fibers to ensure that they do not negatively impact the workability or density of the lightweight concrete.

- Q: Is melt extract stainless steel fiber compatible with all types of shotcrete mix designs?

- Compatibility of melt extract stainless steel fiber with all types of shotcrete mix designs is not guaranteed. Several factors, including fiber length, aspect ratio, dosage, and desired concrete properties, influence the fiber's compatibility with a specific mix design. Shotcrete applications commonly utilize melt extract stainless steel fibers to enhance concrete strength, toughness, and durability. However, careful selection of fiber length and dosage is necessary to ensure compatibility with the specific shotcrete mix design. Various shotcrete mix designs possess different requirements and properties, such as workability, slump, and setting time. Some mix designs may contain higher water content, which can impact the bonding between fiber and concrete matrix, resulting in reduced performance. Consulting with the manufacturer of melt extract stainless steel fiber and the shotcrete mix design supplier is crucial to determine compatibility. They can offer guidance on the appropriate dosage and fiber length to achieve desired results and ensure compatibility with the specific mix design. Additionally, conducting tests and trials on a small scale can aid in evaluating fiber compatibility and performance in the chosen shotcrete mix design.

- Q: Can melt extract stainless steel fiber be used in roundabout pavements?

- Yes, melt extract stainless steel fiber can be used in roundabout pavements. Stainless steel fiber is commonly used in concrete applications to enhance its strength, durability, and resistance to cracking. In roundabout pavements, where heavy traffic and frequent turning movements occur, the use of stainless steel fibers can provide additional reinforcement to prevent cracking and increase the overall performance of the pavement. The fibers are typically added to the concrete mix during the mixing process and are evenly distributed throughout the pavement, providing a uniform reinforcement system. Additionally, stainless steel fibers have high corrosion resistance, ensuring that the pavement remains structurally sound even in harsh environmental conditions. Overall, the use of melt extract stainless steel fiber in roundabout pavements can significantly improve their longevity and reduce maintenance costs.

- Q: How does melt extract stainless steel fiber enhance the crack resistance of concrete?

- The crack resistance of concrete is enhanced by melt extract stainless steel fiber through various mechanisms. Firstly, the inclusion of stainless steel fibers in the concrete mix augments its tensile strength. As a result, the concrete becomes more capable of withstanding forces that lead to cracking, such as shrinkage, temperature fluctuations, and external loads. The fibers assist in distributing these forces uniformly across the concrete, thereby diminishing the probability of crack formation. Secondly, stainless steel fibers act as reinforcement within the concrete matrix. In the event of cracks, the fibers help hold the concrete together and hinder the propagation of cracks. This contributes to the overall durability and longevity of the concrete structure. Moreover, melt extract stainless steel fibers also improve the impact resistance of concrete. They absorb and disperse energy from impacts, decreasing the likelihood of crack formation or propagation caused by sudden loading. Furthermore, stainless steel fibers can enhance the concrete's resistance to chemical attack. They serve as a physical barrier that impedes the penetration of aggressive chemicals, such as chlorides or sulfates, into the concrete. This safeguards the concrete against deterioration and reduces the risk of crack formation due to chemical exposure. In conclusion, melt extract stainless steel fiber enhances the crack resistance of concrete by boosting its tensile strength, reinforcing the concrete matrix, increasing its impact resistance, and providing a barrier against chemical attack. These combined effects result in a more durable and crack-resistant concrete structure.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type CE Approved High Quality Hooked

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords