Melt Extract Stainless Steel Fiber - Glued Hooked-End Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Model Number: 0.9

Material: Steel

Production Process: Cold drawn

Lengh: 55

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 61

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Packaging & Delivery

| Packaging Details: | 20 kg/Bag,50 bags/Pallet or 1,000kg/ Bulk Bag |

|---|---|

| Delivery Detail: | 1 Month |

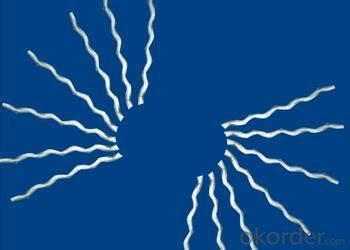

Product Description

| Diameter | 0.90 | mm | 0.04 | in |

| Length | 55.00 | mm | 2.16 | in |

| Aspect Ratio | 61 | |||

| Tensile strength | 1200 MPa | |||

| Type | Cold drawn Steel Fiber | |||

| End | Hooked-end Steel Fiber | |||

| Glued/Loose | Glued Steel Fiber | |||

| Bending Angle | 45°(min.30°) | |||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | |||

| Shotcrete :Slope stabilization and Final lining | ||||

| Precast concrete:Pipe and Railway sleepers | ||||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet | |

| Bulk Packing | 1,000kg/ Bulk Bag | |||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | ||

| 40’GP | 25-27 Tonne/Tonnes | |||

| 40’HQ | 25-27 Tonne/Tonnes | |||

| MOQ | 1 kg for trial order | |||

| Supply Ability | 10,000 Tonne/Tonnes per Year | |||

| Payment Terms | T/T or L/C at sight | |||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||

| Certification | ISO9001:2000, CE, | |||

| Product | Diameter | Length mm/in | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 mm (0.0197 in) | 30 mm (1.1811 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 mm (0.0217 in) | 35 mm (1.3780 in) | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 mm (0.0236 in) | 35 mm (1.3780 in) | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 mm (0.0295 in) | 60 mm (2.3622 in) | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 mm (0.0354 in) | 60 mm (2.3622 in) | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

- Q: What is the effect of melt extract stainless steel fiber on the plastic settlement of concrete?

- The use of melt extract stainless steel fiber in concrete has a positive effect on reducing the plastic settlement of the material. The addition of stainless steel fibers helps to improve the overall performance and durability of the concrete by enhancing its resistance to cracking and shrinkage. When concrete is in its plastic state, it is vulnerable to settlement due to its high water content and the effects of gravity. This settlement can result in an uneven and weakened surface, compromising the structural integrity of the concrete. However, by incorporating melt extract stainless steel fibers into the mix, the fibers act as reinforcement, providing an effective mechanism to counteract plastic settlement. The stainless steel fibers help to distribute the stress and load evenly throughout the concrete, preventing concentrated settlement in specific areas. This even distribution improves the overall homogeneity and stability of the concrete, reducing the risk of cracking and surface deformations. Furthermore, melt extract stainless steel fibers have a high aspect ratio and excellent bonding properties with the cement matrix. This ensures that the fibers are well dispersed and securely anchored within the concrete, enhancing their ability to resist plastic shrinkage and settlement. Overall, the incorporation of melt extract stainless steel fibers in concrete significantly reduces the plastic settlement, improving the overall quality and longevity of the material. This leads to a more durable and structurally sound concrete that can withstand various external factors, such as load, temperature changes, and environmental conditions.

- Q: Can melt extract stainless steel fiber enhance the flexural strength of concrete?

- Indeed, the incorporation of melt extract stainless steel fibers can increase the flexural strength of concrete. By adding these fibers, one can enhance the tensile and flexural properties of the material, thereby reducing cracks and improving its durability. Melt extract stainless steel fibers offer several advantages over other types of fibers. They are produced through the melting of stainless steel, ensuring their high tensile strength and resistance to corrosion. Consequently, they can be utilized for various applications, including concrete reinforcement. When melt extract stainless steel fibers are introduced to concrete, they create a three-dimensional support network that enhances the material's flexural strength. Additionally, they enhance the bond between the concrete matrix and the fibers, lowering the risk of failure when exposed to bending or flexural loads. Moreover, the inclusion of melt extract stainless steel fibers in concrete also bolsters its resistance to cracking. These fibers act as bridges across cracks, impeding their propagation and ultimately resulting in increased toughness and durability. Consequently, this makes the concrete more suitable for structural applications that require heightened flexural strength. Furthermore, melt extract stainless steel fibers can enhance the impact resistance of concrete. Their presence enables the absorption and distribution of impact energy, mitigating the likelihood of sudden failure or breakage. In conclusion, melt extract stainless steel fibers are an effective means of enhancing the flexural strength of concrete. By augmenting the material's tensile and flexural properties, they reduce cracking and improve its overall durability. As a result, these fibers serve as a reliable and efficient reinforcement option for concrete structures that necessitate increased flexural strength, as well as improved resistance to cracking and impact.

- Q: Can melt extract stainless steel fiber be used in lightweight shotcrete applications?

- Melt extract stainless steel fiber is a viable option for lightweight shotcrete applications. Adding stainless steel fibers to shotcrete mixes has proven to enhance the overall strength, durability, and crack resistance of the concrete. By incorporating stainless steel fibers, the flexural and tensile strength of the shotcrete can be significantly improved, which is particularly important for lightweight applications that require strong structural integrity. Moreover, stainless steel fibers also contribute to reducing shrinkage and thermal cracking, making them a suitable choice for lightweight shotcrete applications. However, it is crucial to carefully consider the specific requirements and specifications of the project and seek guidance from a structural engineer or shotcrete expert to ensure the appropriate fiber content and mix design for a successful application.

- Q: Can melt extract stainless steel fiber be used in underground utility structures?

- Yes, melt extract stainless steel fiber can be used in underground utility structures.

- Q: Does melt extract stainless steel fiber improve the resistance to efflorescence in concrete?

- Concrete can benefit from the addition of melt extract stainless steel fiber in order to enhance its resistance against efflorescence. Efflorescence is a phenomenon that arises when soluble salts are transported to the concrete surface through moisture and react with carbon dioxide, leading to the formation of unattractive white deposits. By incorporating melt extract stainless steel fiber into the concrete mixture, these fibers can contribute to reducing the occurrence of efflorescence. Their presence in the concrete enhances its durability and performance by offering reinforcement and minimizing crack formation. Consequently, this helps to limit the entry of moisture and prevents the migration of salts to the concrete surface. Additionally, the stainless steel fibers possess a remarkable resistance to corrosion, enabling them to withstand exposure to various environmental conditions that may contribute to efflorescence. This resistance ensures that the fibers continue to provide reinforcement and prevent the deterioration of the concrete over an extended period of time. In conclusion, melt extract stainless steel fiber can serve as an effective remedy for enhancing the concrete's resistance against efflorescence, promoting long-lasting durability and aesthetic appeal to the structure.

- Q: How is melt extract stainless steel fiber manufactured?

- Melt extract stainless steel fiber is manufactured through a process called melt extraction, where stainless steel is melted and then rapidly cooled to form thin, elongated fibers. These fibers are then further processed and cut to the desired length, resulting in high-quality stainless steel fibers that can be used in various applications such as reinforcement in concrete or as a conductive material in electrical systems.

- Q: Can melt extract stainless steel fiber be used in architectural precast concrete applications?

- Architectural precast concrete applications can benefit from the utilization of melt extract stainless steel fiber. It is a common practice to incorporate stainless steel fibers into concrete mixes in order to enhance the overall strength, durability, and performance of the final product. By utilizing stainless steel fibers in architectural precast concrete, the structural integrity of the panels can be improved, making them more resistant to cracking, impact, and other types of damage. Moreover, the implementation of stainless steel fibers in architectural precast concrete can enhance the visual appeal of the panels by reducing surface defects and improving the overall finish. These fibers also offer additional reinforcement to the concrete, allowing for thinner and lighter panels without compromising strength. Melt extract stainless steel fibers are particularly well-suited for architectural precast concrete applications due to their high tensile strength, corrosion resistance, and ability to withstand extreme temperatures. These fibers are manufactured using a specialized process that guarantees consistent quality and performance. In conclusion, incorporating melt extract stainless steel fiber in architectural precast concrete applications is highly recommended as it can significantly enhance the durability, strength, and aesthetics of the panels.

- Q: Can melt extract stainless steel fiber be used in heavy-duty industrial pavements?

- Indeed, heavy-duty industrial pavements can utilize melt extract stainless steel fiber. Renowned for their remarkable tensile strength, resistance to corrosion, and long-lasting nature, stainless steel fibers prove ideal for challenging applications like heavy-duty industrial pavements. By incorporating these fibers into the concrete, the mechanical properties of the pavement, such as crack resistance, impact resistance, and abrasion resistance, can be greatly enhanced, resulting in improved overall performance and longevity. Moreover, the utilization of stainless steel fibers can also minimize the necessity for traditional reinforcement methods, like steel bars or mesh, leading to cost savings and simplified construction processes. All in all, due to its exceptional properties and associated advantages, melt extract stainless steel fiber constitutes a feasible choice for heavy-duty industrial pavements.

- Q: How does melt extract stainless steel fiber affect the fatigue resistance of concrete?

- Concrete can greatly benefit from the addition of melt extract stainless steel fibers, as they enhance its fatigue resistance and overall durability. These fibers possess unique properties, including high tensile strength and excellent corrosion resistance, which contribute to their ability to reinforce the concrete and prevent cracks from spreading under cyclic loading. When melt extract stainless steel fibers are evenly dispersed throughout the concrete mixture, they create a three-dimensional network that improves the structural integrity of the material. This network helps distribute stress evenly, reducing the risk of fatigue failure by minimizing stress concentrations. Furthermore, the high corrosion resistance of stainless steel fibers ensures that they maintain their structural integrity over time. This is particularly important in concrete structures exposed to harsh environmental conditions or corrosive agents, as the fibers will not degrade or weaken due to corrosion, thus preserving their beneficial effects on fatigue resistance. In conclusion, the incorporation of melt extract stainless steel fibers into concrete significantly enhances its ability to withstand cyclic loading and repetitive stress. These fibers act as crack arresters, distribute stress more evenly, and provide long-term durability due to their corrosion resistance.

- Q: How does melt extract stainless steel fiber affect the resistance of concrete to carbonation?

- Melt extract stainless steel fiber can significantly improve the resistance of concrete to carbonation. Carbonation occurs when carbon dioxide from the atmosphere reacts with the calcium hydroxide in the concrete, forming calcium carbonate. This process reduces the alkalinity of the concrete, leading to a decrease in its durability and strength. By adding stainless steel fibers to the concrete mix, the carbonation process can be mitigated. The stainless steel fibers act as a physical barrier, preventing the ingress of carbon dioxide into the concrete matrix. This barrier effect is particularly effective in reducing carbonation depth, which is crucial for maintaining the long-term durability of concrete structures. Furthermore, stainless steel fibers enhance the mechanical properties of the concrete. They improve the tensile strength and ductility of the material, making it more resistant to cracking and subsequent carbonation. The fibers also enhance the bond between the cement paste and the aggregates, further increasing the durability of the concrete. In summary, the addition of melt extract stainless steel fiber to concrete greatly improves its resistance to carbonation. It acts as a barrier against carbon dioxide ingress, reduces carbonation depth, enhances mechanical properties, and ultimately prolongs the service life of concrete structures.

Send your message to us

Melt Extract Stainless Steel Fiber - Glued Hooked-End Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords