Melt Extract Cold Drawn Stainless Steel Fiber 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

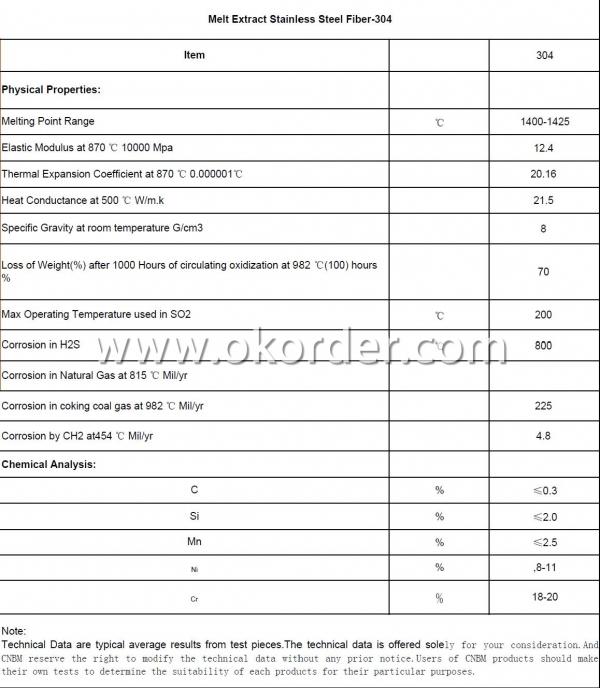

General Information of Cold Drawn Stainless Steel Fiber 304

CMAX cold drawn stainless steel fiber is manufactured by high quality stainless steel wire, mainly used for castable requirements in refractory field, with high tensile strength and low ductility. Cold drawn stainless steel fiber is accomplished by high quality stainless steel wire, and is mainly used for refractory castables. CMAX steel fiber has the ultra-strong tensible strength and suppleness.

CMAX cold drawn stainless steel fiber can improve refractories performance and durability, decreasing cost.

Feature of CMAX Cold Drawn Stainless Steel Fiber 304

Improve refractories’ performance

Improve refractories’ longevity

Improve refractories’ durability

Significantly reducing downtime and maintance cost

Application of CMAX Cold Drawn Stainless Steel Fiber 304

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiberproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price.

- Q: How does melt extract stainless steel fiber impact the early-age cracking of concrete?

- Melt extract stainless steel fiber reduces the early-age cracking of concrete by improving its tensile strength and crack resistance. The fibers effectively distribute and restrain the shrinkage stresses within the concrete, preventing the formation of significant cracks during the early stages of curing. This reinforcement also enhances the overall durability and longevity of the concrete structure.

- Q: How does the dosage of melt extract stainless steel fiber affect its performance in concrete?

- The dosage of melt extract stainless steel fiber directly impacts its performance in concrete. Increasing the dosage of stainless steel fiber enhances the concrete's resistance to cracking, improves its flexural and tensile strength, and enhances its durability. Higher dosages of stainless steel fiber also enhance the concrete's resistance to impact and abrasion. However, excessive dosage may lead to an increase in the viscosity of the concrete mix, which can affect its workability. Therefore, finding the optimal dosage is crucial to achieve the desired performance in concrete.

- Q: Is melt extract stainless steel fiber suitable for use in high-performance mortar?

- Yes, melt extract stainless steel fiber is suitable for use in high-performance mortar. Stainless steel fibers are known for their exceptional strength, durability, and corrosion resistance, making them ideal for applications that require high-performance materials. When added to mortar, these fibers can enhance the overall performance of the mortar by improving its tensile and flexural strength, reducing cracking, increasing impact resistance, and enhancing durability. Additionally, melt extract stainless steel fibers have a high melting point, which allows them to withstand high temperatures without losing their mechanical properties. This makes them particularly suitable for high-performance applications where the mortar will be exposed to extreme conditions or thermal stresses. Overall, melt extract stainless steel fiber can significantly improve the performance and lifespan of high-performance mortar.

- Q: Can melt extract stainless steel fiber be used in concrete repair applications?

- Yes, melt extract stainless steel fibers can be used in concrete repair applications. These fibers enhance the strength and durability of concrete by providing reinforcement and improving crack resistance. They are effective in preventing crack propagation and improving the overall performance of repaired concrete structures.

- Q: How does melt extract stainless steel fiber improve the bond strength of shotcrete?

- Melt extract stainless steel fiber improves the bond strength of shotcrete by providing additional reinforcement and enhancing the connection between the shotcrete mix and the substrate. The fibers act as a network of reinforcement within the shotcrete, increasing its tensile strength and preventing crack propagation. This ultimately leads to a stronger bond between the shotcrete and the surface, improving the overall durability and performance of the shotcrete application.

- Q: The steel fiber concrete cover per cubic concrete how much steel fiber

- The design is specified, usually according to the total amount of cementitious material

- Q: Can melt extract stainless steel fiber be used in tunnel linings or underground structures?

- Melt extract stainless steel fiber is a viable option for tunnel linings and underground structures. Using stainless steel fiber in such applications offers numerous advantages. To begin with, the incorporation of stainless steel fiber enhances the strength and durability of the structure as a whole. Stainless steel possesses excellent tensile strength and is resistant to corrosion, making it an ideal material for reinforcing tunnel linings. By adding stainless steel fiber to concrete or shotcrete mixes, the flexural strength and crack resistance of the structure are improved, ultimately increasing the lifespan and structural integrity of the tunnel lining. Additionally, stainless steel fiber provides improved fire resistance. In the event of a fire, stainless steel fiber aids in minimizing flame propagation and reducing the likelihood of structural collapse. This is particularly crucial in underground structures where fire safety is of utmost importance. Moreover, stainless steel fiber contributes to the overall safety of tunnel linings and underground structures. By enhancing crack resistance and structural stability, it mitigates the risks of sudden failures or collapses, ensuring the safety of both the structure and its occupants. In conclusion, melt extract stainless steel fiber is highly suitable for tunnel linings and underground structures due to its strength, corrosion resistance, fire resistance, and safety benefits. Its inclusion in concrete or shotcrete mixes can significantly enhance the overall performance and longevity of these structures.

- Q: Can melt extract stainless steel fiber be used in swimming pool structures?

- Swimming pool structures can indeed incorporate melt extract stainless steel fiber. The attributes of stainless steel fibers, such as their exceptional strength, durability, and resistance to corrosion, make them highly suitable for a diverse range of applications, including swimming pool structures. By introducing these fibers into the concrete mix utilized for constructing pool walls, floors, and other components, their overall strength and durability can be significantly enhanced. Moreover, the presence of stainless steel fibers aids in the prevention of cracking and boosts resistance to water and chemical damage, a particularly crucial factor within a swimming pool environment. Furthermore, the utilization of stainless steel fibers contributes to the elongation of the lifespan and improvement of the overall performance of the pool structure, thereby reducing the necessity for maintenance and repairs.

- Q: What is the typical fiber length and diameter of melt extract stainless steel fiber?

- The specific manufacturer and application requirements can cause variations in the typical fiber length and diameter of melt extract stainless steel fiber. However, a general range for the length of these fibers is typically from a few millimeters to several centimeters. The diameter of these fibers can range from around 10 micrometers to 50 micrometers. These dimensions are carefully selected to ensure the desired properties, such as strength, durability, and thermal conductivity, for a variety of applications. These applications include reinforcement in composites, thermal insulation, and electromagnetic shielding.

- Q: Can melt extract stainless steel fiber be used in tunnel rehabilitation projects?

- Yes, melt extract stainless steel fiber can be used in tunnel rehabilitation projects. It is commonly used to enhance the strength and durability of concrete in such projects, as it provides reinforcement and helps prevent cracking and deterioration of the structure.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Melt Extract Cold Drawn Stainless Steel Fiber 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords