Melamine Faced MDF for Furniture High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

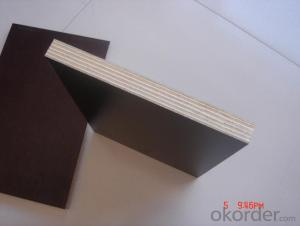

Item-Melamine Faced MDF

Size-1220x2440mm

Thickness-2.5mm-30mm

Description

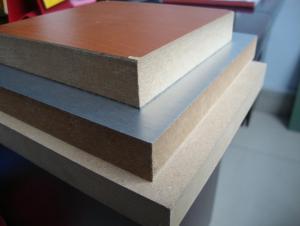

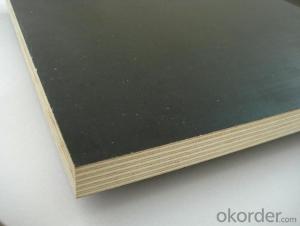

Product Name | Melamine Faced Texture MDF Wood Board | ||

Size | 1220x2440mm, 915x2135mm or as clients requirement | ||

Thickness | 2~25mm | ||

Thickness Tolerance | +/-0.2mm | ||

Face/Back | Melamine faced (one side or both side melamine faced) | ||

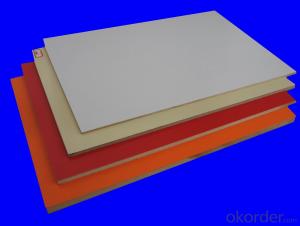

Surface Treatment | Textured (There also have matt, glossy, embossed or magic) | ||

Melamine PaperColor | Solid color (such as grey, white, black, red, blue, orange, green, yellow, ect.) & wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, wenge, rosewood, ect.) & cloth grain & marble grain. More than 1000 kinds color are available. | ||

Melamine Paper Gram | 80~120g/m2 | ||

Core Material | Wood fiber (poplar, pine or combi) | ||

Glue | E0, E1 or E2 | ||

Grade | A grade or as clients requirement | ||

Density | 730~750kg/m3 (thickness>6mm), 830~850kg/m3 (thickness≤6mm) | ||

Technical Parameters | Moisture Content | ≤8% | |

Water Absorption | ≤12% | ||

Modulus of Elasticity | ≥2500Mpa | ||

Static Bending Strength | ≥22Mpa | ||

Surface Bonding Strength | ≥1.20Mpa | ||

Internal Bonding Strength | ≥0.55Mpa | ||

Screw Holding Ability | Face | ≥1300N | |

Edge | ≥800N | ||

Usage & Performance | Melamine MDF is widely used for furniture, interior decoration and wood flooring. With good properties, such as, acid & alkali resistant, heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect. | ||

Packing | Loose packing | ||

Standard export pallet packing | |||

MOQ | 1x20’FCL | ||

Supply Ability | 10000cbm/month | ||

Payment Terms | T/T or L/C at sight | ||

Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

Certification | ISO9001:2000, CE, CARB | ||

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- Large areas of the current general offset printing, letterpress printing and other printing methods, the size of the largest paper size, the entire area of more than a full sheet size, it is limited by mechanical equipment. Screen printing can be a large area of printing, screen printing products today can reach up to 3 meters x 4 meters, or even higher significantly.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q: Carton printing process and materials

- Art paper gravure composite carton process, when the production of large quantities, without film, and requires good printing effect, low cost, you can use this process. This process is to use paper gravure printing machine printing thin coated paper, and then the printed coated paper and ordinary slag paper board or cardboard composite as a whole, carton paper, and then mounted on the carton forming normal.The process is characterized by:(1) the cost of making cartons is low. The main reason for the cost reduction is that the white board is changed into low weight coated paper, which is combined with cheap carton paper to reduce material cost.(2) beautifully printed. The gravure printing effect of paper is very exquisite.(3) gravure printing process is more complicated, and the cost is high, it is not suitable for printing, often revised carton products.(4) the operation and control methods of the printing process, such as paper compounding and box making, should be carefully explored and continuously accumulated and reasonably implemented. Otherwise, the waste rate will be easily increased.

- Q: What are the materials used in screen printing?

- Divided into printed screen and printed material, screen according to different processes are divided into water-based and solvent based, printed material according to different substrate is divided into ink and ink

Send your message to us

Melamine Faced MDF for Furniture High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords