Melamine Faced Particle Board 16mm for Furniture and Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 10000 CBM/month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

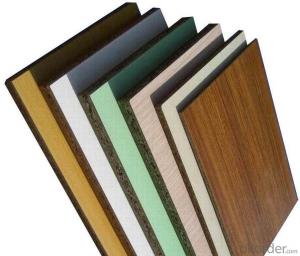

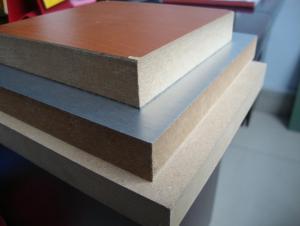

Specifications of Melamine Faced MDF Boards:

Name:Melamine Faced MDF Boards Manufacturer for Furniture and Decoration

Quality standard: GB/T 15102-2006

Size: 1220x2440mm (4'*8')

Thickness: 2.5mm to 25mm or as customised

Formaldehyde emission: E1,E2, E0, Cabon P2

Density: 650kg/m3-820kg/m3

Surface texture: Quality UV lacquered,corner with ABC protecting

Certificate:ISO9001,FSC,

Usage:Widely used for kitchen cabinet,showcase

Packing:Pallet packing or any sea worthy packing

Lead time:10-30 days after done payment

____________________________________________________________________________________________

Features of Melamine Faced MDF Boards:

1:High eco-friendly.low VOC discharge

2:Excellent glossy and mirro effect,surface hardness with 3H which difficult to make scratch

3:Smooth surface easy to clean and durable

4:Moisture-proof, fire-proof,anti-acid and anti-alkali against a variety of disinfector

5:OEM,designed painting would be welcome

__________________________________________________________________________________________

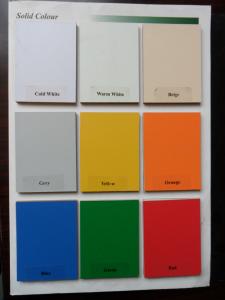

Various Color Choices

Our Factory

- Q: Plywood hot press and plywood hot press is different

- Plywood hot press according to the operating mode sub-cycle and continuous two kinds of domestic commonly used is a multi-layer multi-cycle hot press. It consists of three parts: hot press body, control drive part (hydraulic system and electronic control system), heating system.

- Q: Will the fire board be used as a plywood for furniture?

- of course. And is a good choice.

- Q: The good and the bad of wood is not determined by the severity

- 1, see: the quality of the board should be smooth and smooth, no defects, from the side to see whether the thickness of the core plate, blockboard and multilayer will have to observe whether the phenomenon of overlapping core. The panel is made of rice (usually white). You can keep the long-term smoothness of the panel. Generally a stack of plywood texture is no difference between the artificial veneer veneer, dyed veneer, just in the selection, dipped in water, gently rub off, fade that is dyed; natural veneer plywood nice,

- Q: What are the shortcomings and advantages of oak plywood?

- Oak furniture advantages: oak furniture, wood is relatively hard, relatively strong stability, texture is relatively clear, made out of furniture durable, very simple fashion. Made out of the furniture are very upscale, especially suitable for European furniture. Placed at home also appears to be on the grade, grain clear appearance beautiful, is the furniture of the Jiao Jiao who.

- Q: What are the types of wood panel?

- 3. Teak: hard texture, fine and durable, wear-resistant corrosion, not easy to deformation, shrinkage rate is the smallest of a wood. The plate can be used for solid wood flooring, decorative panels for furniture, wall.

- Q: What are the advantages of ecological boards and other boards?

- Consumers in the selection of such plate furniture, in addition to taking into account the color and texture satisfaction, but also from several aspects to identify the appearance of quality: whether stains, scratches, indentation, porosity, color gloss is not uniform, there is no Bubbling phenomenon, with or without local paper tear or defect phenomenon and so on. If the phenomenon of veneering cracking or damage, you can use the following methods to repair: first in the damaged place to put a damp cloth, and then put a hot iron on the hot cloth, forcing the moisture into the veneer, so that the veneer becomes tough and difficult Fragmentation. So that you can first clean the old plastic, and then coated with a layer of milk at the grass layer of wood, and then in the loose surface of the negative coated with a layer of new plastic, compaction, to be completely dry glue.

- Q: Is the wooden door good for solid wood or plywood?

- Natural environmental protection, which is the biggest feature of solid wood furniture. Compared with those wood-based panels, the amount of glue is relatively small. The amount of plastic with the impact of the environmental impact of the level of furniture.

- Q: What are the patterns of kitchen design?

- 1. Sliced ??wood veneer plywood Sliced ??veneer is made of precious wood species with radial slicing process made of wood veneer, the thickness of thin board. Different materials, different patterns, paste on the man-made board on a variety of ways, which is characterized by real nature, no cracking, no deformation, and save wood, environmentally friendly, is the highest market share at home and abroad today Veneer. But this kind of decorative panels for the use of precious trees as raw materials, so the cost is high, so they appeared in the use of fragmented wood processing waste, coloring, bonding, cut into thin slices, used to give man-made veneer, the effect even better than Sliced ??wood veneer.

- Q: How many types of wooden lines

- Wood-plastic lines, is the use of domestic booming in recent years, a new type of composite materials, refers to the use of polyethylene, polypropylene and polyvinyl chloride, instead of the usual resin adhesive, and more than 35% -60% , Straw and other waste plant fiber mixed into a new wood material, and then by extrusion processing and output. Mainly used to replace the wood lines and plaster lines.

- Q: White European furniture oak veneer good or smooth look good

- White furniture on the market are smooth, and good care

Send your message to us

Melamine Faced Particle Board 16mm for Furniture and Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 10000 CBM/month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords