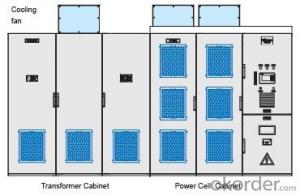

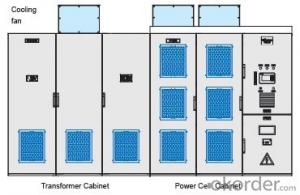

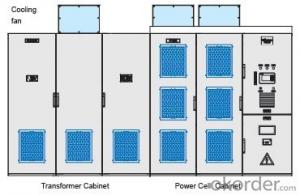

Medium Voltage Drive VFD 2250KW 6.6KV HIVERT-Y 6.6/243

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Torque limiting function

The torque limit function is used to accurately control and limit the torque in order to prevent overload of the motor,

electricity supply system or VFD itself. This prevents damage to the motor when stationary, for example, with a

locked rotor, when starting with high inertia or high initial friction load.

The torque limit function can also be used to prevent or limit the return of power from the motor to the VFD in the event

of an over-hauling load causing the motor speed to exceed the commanded speed.

Spinning start (Flying start)

The RMVC 5100 can automatically identify that the motor is already spinning at the moment of the start request and

institute a controlled sequence to enable the drive to pick up the spinning motor without the need to stop the motor or

the risk of a system trip. The sequence requires an initial estimate of the spinning motor speed by scanning the

motor voltage while changing the output frequency. Steps are taken to reduce the time needed to estimate the motor

speed.

Examples of when a Flying Start would be used

∙ The mechanical load causes the motor to be spinning, even though no electric power is applied to the motor.

∙ Manual reset after trip

∙ Automatic restart after a shutdown.

∙ Restart after Low-Voltage Ride-Through (temporary loss of supply power).

∙ Restart after an automatic Power Cell Bypass.

- Q: I have a 11KW-4 pole inverter, now with the 4KW-4 pole motor, what impact?

- 11KW the following can be brought, the inverter rectifier module may be broken,

- Q: Servo control system can give the inverter signal,

- If two motors are to be synchronized, only two servomotors are used, one is set to spindle and the other is set to slave.

- Q: What is the single axis of the inverter and multi-axis applications

- Inverter is the application of frequency conversion technology and microelectronics technology, by changing the motor power supply frequency and amplitude of the way to control the AC motor power transmission components.

- Q: My inverter is the era TVF8000 series, the motor is 15KW6 pole motor, has been used for 3 years.

- Motor current when the current 10A this has no effect on you, the rated current is 31.4A, your inverter is selected how many W, is the fan pump type or universal? Now the motor operating current reached 34-35A, more than the rated current, then the motor may have two problems, one is the motor leakage powerful, and in a motor is overload, resulting in increased current

- Q: Variable frequency pump pressure in the very low flow instability, why?

- . If you want to stabilize the pressure, you must adjust the pipeline characteristic curve is the work point to enhance, so that you can both stabilize the pressure and adjust the flow.

- Q: How to disassemble the notebook power adapter

- 3, then open the shell of the power adapter, you can see the adapter circuit outside the package with a copper shield, with a knife to cut the shielding tape on the tape, and then use the soldering iron shield and the internal circuit board connected to the two Solder joints, you can remove the shield.

- Q: Speed regulation method of three - phase asynchronous motor

- 1, frequency control, with the inverter, power 2, change the magnetic pole logarithm, not feasible. 3, stator series resistance, energy consumption

- Q: My motor is a low frequency 8 pole motor, about 80W. I would like to choose a frequency converter

- VACON frequency converter (Finland wholly owned) Model: NXL 0006 2 C1N1 Parameters: Low overload Continuous current: 6.6A 110% Overload current: 7.2A 110% Overload power: 1.5kw (ambient 40 ℃) High Overload Continuous Current: 4.8A 150% Overload Current: 7.2A 150% Overload Power: 1.1kw (Ambient 50 ℃) Maximum current: 9.6A Weight: 2.0kg Mechanical specifications: 84 x 220 x 172 Please consult the pre-sale technical support department

- Q: Fuji inverter motor set the number of poles will not have any effect?

- The number of poles is not the same as the speed is not the same mistake machine can not work or motor coil burned

- Q: What is the IGBT? Our inverter IGBT fried,

- Basically change the voltage, the voltage changes in accordance with the different frequencies, so that change the speed.

Send your message to us

Medium Voltage Drive VFD 2250KW 6.6KV HIVERT-Y 6.6/243

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords