Medium-frequency induction furnace 10Ton

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

The essence of the furnace is a kind of power supply device rectifying three-phase alternating current power to direct current

Medium frequency furnace

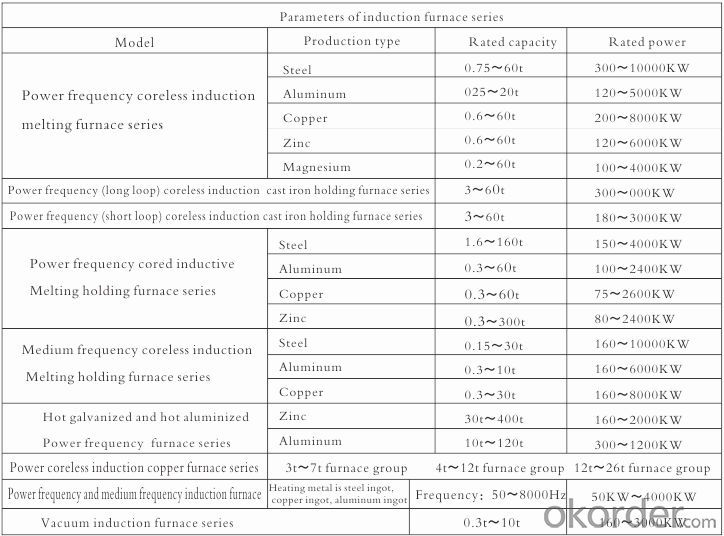

Product specification:

Medium-frequency induction furnace is the power supply device converting alternating current power to intermediate frequency power. The essence of the furnace is a kind of power supply device rectifying three-phase alternating current power to direct current and then changing direct current to adjustable current by inversion device to supply it to resonance circuit composed by capacitance and induction coil. Strong magnetic field is produced in induction coil, which makes metal material in induction coil produce big eddies. The resistance of metal itself can produce large amount of heat when large current passing. Therefore, metal material will become hot quickly.

Our company’s medium frequency induction furnace and power frequency induction furnace are widely used to smelting of non-ferrous metal ( It mainly is used in melting steel, alloy steel,special steel, cast steel and other ferrous materials, as well as the melting of stainless steel, copper, aluminum, zinc and other nonferrous materials. It can operate duplex with blast furnace.) It also widely used in forging heating and tempering heat treatment production line.

Features of medium melting furnace:

(1) The efficiency of melting is high, power-saving effect is good. The structure is compact. And the overload capacity is high.

(2) There is low temperature, few smoke dust and comfortable operating situation around furnace.

(3) Operation process is easy and smelting running is reliable.

(4) Metal components is well-distributed.

(5) Heat of melting is fast. Temperature of furnace is easy to control. Efficiency of production is high.

(6) The usage of furnace is high. And it is convenient to change types.

Features of medium diathermanous furnace:

(1) Fast speed of heating, high productive efficiency, low oxidation decarburization, saving materials and cost of forging dies

(2) Conductive working environment, improving the working condition and image of company, environmental protection and low energy consumption

(3)Evenly heating, extremely low temperature difference of table core, high precision temperature control

- Q: Selection of heat preservation material for industrial furnace

- Ceramic fiber blanket can be used.Ceramic fiber blanket color white, regular size, set fire, heat insulation, insulation in one. Free from any binding agent.

- Q: What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q: What is industrial furnace masonry?

- Before masonry construction, the pre process and parts that may affect the quality of masonry work shall be re tested,masonry construction shall be carried out according to the datum central line and the datum elevation.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Furnace industry is not generally Mason walls, needs to have a professional operation and rich construction experience, high level of industrial furnace is difficult to get.

- Q: What is the difference in structure between industrial furnace and boiler?

- From the way: industrial furnace (electricity, natural gas, gas, induction heating is considered electricity), boilers (coal, all kinds of hot exhaust gas, a variety of gas, seemingly less electricity).

Send your message to us

Medium-frequency induction furnace 10Ton

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords