China BOPP Packaging Tape Masking Film for Car Painting SGS and ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

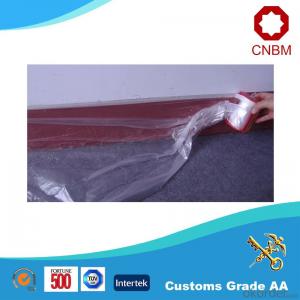

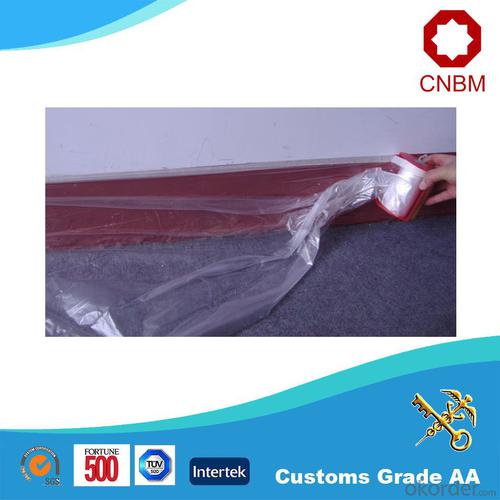

Masking Film For Car Painting SGS and ISO

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. Pretaped with Masking Tape, which is sunlight stable and gives the user 7-day clean removal. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Sunlight stable even on glass

Indoor/outdoor painting

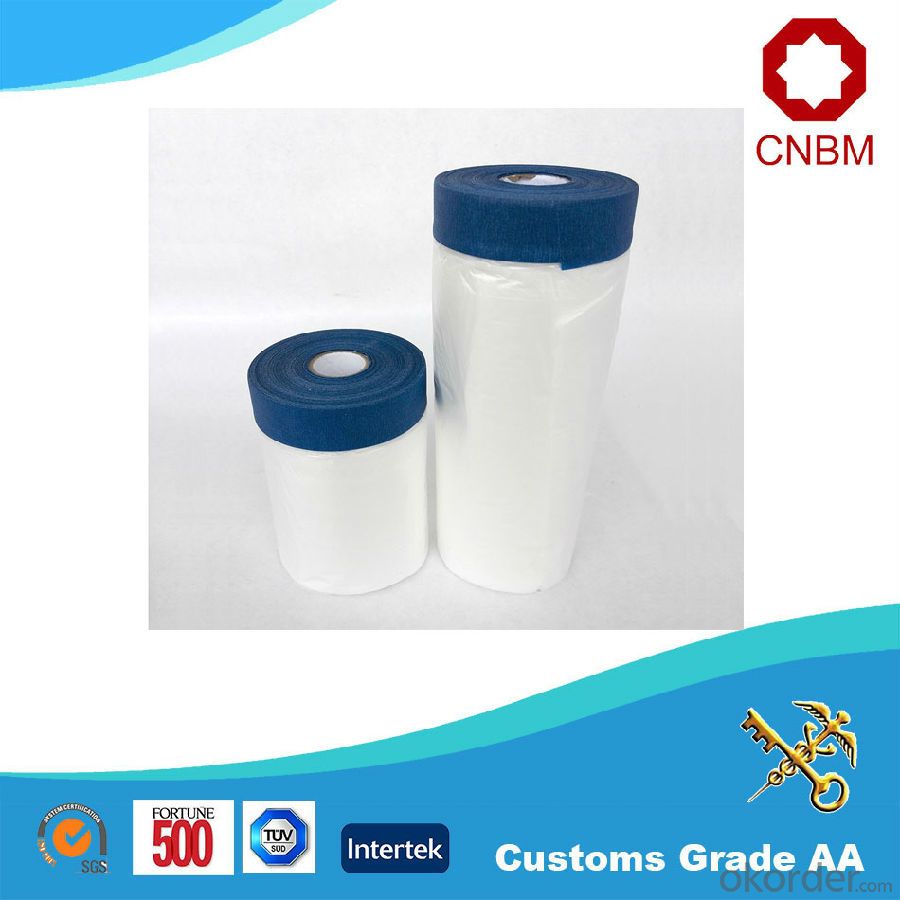

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. Packing and shipping

It is wraped by hot shrink POF film with adhesive lable. 50 rolls or 25rolls packing in to one carton.

After receiving the deposite, it will take around 20 days before shippment.

Q3. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

- Q: Can packaging tape be used for other purposes?

- Packaging tape has a wide range of uses beyond its intended purpose of sealing packages. Its strong adhesive properties and durability make it suitable for various applications. One popular alternative use for packaging tape is organizing and bundling items together. It can be used to sort and secure cables, cords, loose items, or similar objects, effectively keeping them organized. Additionally, it can be used to temporarily attach items like posters or decorations to walls or surfaces without causing any damage. Furthermore, packaging tape is great for crafting and DIY projects. Its adhesive nature allows it to create both temporary and permanent bonds between different materials. It can repair torn papers, create labels or tabs, or even make personalized stickers. Its versatility, available in different widths and lengths, makes it a valuable tool for creative endeavors. Moreover, packaging tape can be used for household fixes and repairs. Its strong adhesive properties can temporarily mend broken items or reinforce weak joints. It can also provide a temporary seal for minor leaks or cracks until a proper repair can be done. In conclusion, packaging tape's strong adhesive properties and versatility make it suitable for various purposes beyond sealing packages. Whether for organizing, crafting, or quick fixes, having packaging tape on hand can be highly useful.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Certainly, retail or product packaging can be effectively sealed using packaging tape. Specifically designed for securely sealing boxes and packages, packaging tape offers a durable seal. Its usage is widespread across various industries, including retail, e-commerce, and product packaging. Made from robust adhesive material, packaging tape guarantees the package remains sealed throughout transportation and handling. Its ease of use allows for quick and efficient application. Moreover, packaging tape comes in a range of sizes and strengths, enabling it to meet diverse requirements for different types of retail or product packaging. In conclusion, packaging tape proves to be a dependable and efficient choice for sealing retail or product packaging.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled, but it depends on the type of tape and the recycling facilities available in your area. Most commonly used packaging tapes, such as clear or brown polypropylene tape, cannot be recycled with regular paper or plastic waste. However, some recycling centers accept certain types of tapes for recycling, such as those made from paper or with water-based adhesives. It is important to check with your local recycling center to determine if they accept packaging tape for recycling and what specific requirements they have. Additionally, removing the tape from cardboard boxes before recycling them can help improve the recycling process. If recycling is not an option, reusing packaging tape or disposing of it properly in the regular trash is recommended.

- Q: What are the different types of packaging tape?

- There are several types of packaging tape available, including clear tape, brown tape, duct tape, masking tape, and double-sided tape. Each type has its own specific use and characteristics, such as transparency, strength, adhesive properties, and thickness.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape is typically resistant to a wide range of chemicals. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC), which are known for their chemical resistance properties. These materials have the ability to withstand exposure to various chemicals, including solvents, acids, and bases. However, it is important to note that the level of chemical resistance can vary depending on the specific type and quality of packaging tape being used. Some tapes may have a higher resistance to chemicals than others. Additionally, the duration and intensity of chemical exposure can also affect the tape's resistance. To ensure the tape's chemical resistance, it is recommended to check the manufacturer's specifications and guidelines regarding chemical compatibility. If you are dealing with particularly harsh chemicals or specialized applications, it may be necessary to seek out specific types of packaging tapes that are specifically designed for those conditions.

- Q: How does packaging tape affect the weight of a package?

- The weight of a package is not directly influenced by packaging tape. Instead, it is determined by the contents within, including the item being shipped, any extra packaging materials, and the actual weight of the packaging. Packaging tape is utilized to secure the package's contents and guarantee their protection during transportation. Although the tape may have a slight weight, it is insignificant compared to the total weight of the package. As a result, the weight of a package is not significantly affected by the packaging tape.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Indeed, one can utilize packaging tape for the purpose of sealing packages containing delicate artwork or sculptures. Nevertheless, it is crucial to exercise caution in selecting the appropriate variant of packaging tape to guarantee the safeguarding of the artwork. In general, it is highly recommended to opt for a top-notch, robust packaging tape that has been explicitly crafted for the purpose of shipping and handling fragile or delicate items. These varieties of tape often possess added reinforcement through the inclusion of fibers or augmented adhesive strength, thereby ensuring a secure seal and averting any potential harm during transportation. Furthermore, it is advisable to employ suitable cushioning materials such as bubble wrap or foam padding to provide adequate protection for the artwork housed within the package.

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. It provides a strong and secure seal to keep the contents of the packaging safe and protected.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q: What is the average width of packaging tape?

- Packaging tape usually has an average width ranging from 1.88 inches to 2 inches. This standardized width ensures effective sealing of boxes and packages, ensuring a secure and dependable closure. Nevertheless, it is worth noting that the market offers different tape widths to cater to specific packaging requirements or personal preferences, with some tapes being narrower or wider.

Send your message to us

China BOPP Packaging Tape Masking Film for Car Painting SGS and ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords