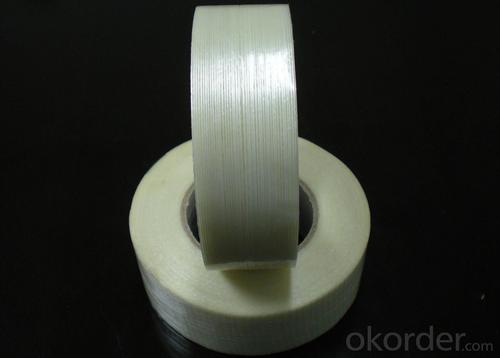

Custom Adhesive High Quality Fiberglass Tape FGT-130

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2. The tape is with high tensile strength, used for palletizing, holding, bundling, reinforcing, heavy duty packing, carton packing & sealing.

3. Standard cut roll packing: one roll per plastic bag, then into cartons. We can also offer special packing as per customer's requirements, such as label, core printing and sticker.

Backing: Bi-directional Fiberglass + PET film

Adhesive: Hot melt rubber based adhesive

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + backing): 160micron

Initial Tack: more than 18# steel ball

Tensile Strength: more than 190N/25mm

Peel Adhesion: 16.5 N/25mm

Holding power: not less than 50h (1kg/25mm)

Mesh: 20/6

Temperature resistance: 60C

Elongation: 1.00%

Sizes:

Jumbo Roll: 1.02 x 1000m

Cut Roll: As per customer's requirements

Packaging Of High Quality Fiberglass Tape FGT-130:

Each Fiberglass Mesh Roll is put into Shrink Bag, and then put into Carton or Pallet. (24 rolls or 48 rolls per carton)

- Q: Does packaging tape come in different thicknesses for added durability?

- Yes, packaging tape does come in different thicknesses for added durability. Thicker tapes are often preferred for heavier or more secure packaging needs, as they provide increased strength and resistance to tearing or breaking.

- Q: What are the advantages of using packaging tape over other sealing methods?

- One advantage of using packaging tape over other sealing methods is its versatility. Packaging tape can be used to seal a wide variety of materials, such as cardboard boxes, plastic bags, and envelopes. It provides a strong and secure seal that can withstand the rigors of shipping and handling. Additionally, packaging tape is easy to use, requiring minimal effort and time for application. It is also cost-effective, as a small amount of tape can go a long way in sealing multiple packages. Lastly, packaging tape is often available in different sizes, colors, and strengths, allowing for customization and meeting specific packaging needs.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Indeed, when it comes to sealing packages with irregular shapes, packaging tape comes in handy. Its flexibility and adhesive nature make it perfect for securing packages of different sizes and contours. Thanks to its strong adhesive properties, packaging tape can adhere to various surfaces, even those that are uneven or irregular, ensuring that the package remains tightly sealed during transportation. Moreover, packaging tape is known for its durability and tear-resistance, providing an added layer of protection for the package. Consequently, whether the package boasts an irregular shape or not, packaging tape proves to be a dependable and efficient choice for sealing it securely.

- Q: How long does packaging tape last?

- The durability of packaging tape is heavily influenced by different factors including the tape's quality, the conditions it encounters, and its storage method. In general, packaging tape has the potential to endure for several months to a few years. Nevertheless, it is crucial to acknowledge that as time goes on, the adhesive qualities of the tape might start to diminish, resulting in a loss of its adhesive strength. Additionally, exposure to extreme temperatures, moisture, and sunlight can expedite the tape's decay. Hence, it is advisable to employ packaging tape within its recommended shelf life and keep it in a cool and dry area to guarantee its efficacy when required.

- Q: How is packaging tape different from regular tape?

- Packaging tape is different from regular tape in several ways. Firstly, packaging tape is designed for heavy-duty use and is specifically made to securely seal boxes and packages for shipping or storage. Regular tape, on the other hand, is generally used for lighter tasks such as gift wrapping or arts and crafts. Secondly, packaging tape is typically wider and thicker than regular tape, providing better strength and durability. This ensures that packages remain securely sealed during transportation and handling, reducing the risk of damage or tampering. Furthermore, packaging tape often has specific features that regular tape may not have. For example, some packaging tapes are designed to be water-resistant or have reinforced fibers for added strength. These features are crucial in protecting packages from moisture, ensuring that the tape does not easily tear, and providing extra security for valuable or fragile items. Lastly, packaging tape often comes in larger rolls or dispensers, allowing for efficient and continuous application. This is especially important when sealing multiple packages or dealing with larger items. Regular tape, on the other hand, is typically available in smaller rolls or individual pieces, making it more suitable for smaller-scale tasks. In summary, packaging tape differs from regular tape in terms of its intended use, strength, durability, specific features, and size options. Its purpose is to provide a reliable and secure seal for packages during transportation and storage, making it an essential tool in the logistics industry.

- Q: Can packaging tape be used for securing pallet loads?

- Indeed, pallet loads can be secured using packaging tape. Although packaging tape is typically utilized for securing boxes and packages, it is also applicable for fortifying and securing pallet loads. It efficiently keeps the items on the pallet intact, averting any potential movements or accidents during transportation or storage. Nevertheless, it is essential to acknowledge that the efficacy of packaging tape in securing pallet loads might rely on the weight and stability of the transported items. There may be instances wherein additional strapping or banding is necessary to provide supplementary security.

- Q: Buy adhesive tape every time, discover its sticky viscosity is insufficient, encounter cold weather, do not use well,

- Peel strength test: tape, stick to specific steel standard width, then the tape from the plate on the tear tape with the robot manipulator, a stabilizing force is reflected in the size of the peeling force.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, there are several steps you can take: 1. Choose the right type of packaging tape: Make sure you are using a high-quality packaging tape that is designed for heavy-duty applications. Look for tapes that are specifically labeled as tear-resistant or reinforced. 2. Prepare the surface: Before applying the tape, ensure that the surface is clean, dry, and free from dust or debris. A dirty or uneven surface can cause the tape to tear easily. 3. Use proper technique: When applying the tape, hold the roll at a slight angle to the surface rather than perpendicular. Applying it at an angle will reduce the amount of friction between the tape and the surface, minimizing the chances of tearing. 4. Apply gentle pressure: Apply the tape smoothly and evenly, using gentle pressure. Avoid pulling or tugging too hard, as it can strain the tape and increase the risk of tearing. 5. Avoid extreme temperatures: Extreme temperatures can affect the adhesive properties of the tape and make it more prone to tearing. If possible, store the tape in a controlled environment and avoid using it in extremely hot or cold conditions. 6. Consider using a tape dispenser: Using a tape dispenser can help you apply the tape more smoothly and evenly, reducing the chances of tearing. It also provides better control and minimizes the strain on the tape. 7. Cut the tape cleanly: When cutting the tape, use a sharp blade or scissors to ensure a clean cut. A jagged or uneven cut can weaken the tape and make it more likely to tear. By following these tips, you can significantly reduce the chances of packaging tape tearing during application and ensure a secure and reliable seal for your packages.

- Q: Is packaging tape safe to use on leather?

- No, packaging tape is not safe to use on leather as it may damage the surface and leave adhesive residue. It is recommended to use specialized leather adhesive or tape for any leather-related tasks.

- Q: How do I cut packaging tape without scissors?

- One way to cut packaging tape without scissors is by using your teeth. Simply hold the tape between your fingers and bite down firmly, then pull your head back to tear the tape. Alternatively, you can use a sharp object like a knife or a box cutter to cut the tape by pressing it against the tape and pulling it in a swift motion. However, be cautious when using sharp objects to avoid any injuries.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | Southeast Asia; South America; Eastern Europe; North America; Northern Europe; South Asia; Western Europe; Africa; Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 51-100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | masking tape, cloth tape, PET tape |

| Product Price Range | Average |

Send your message to us

Custom Adhesive High Quality Fiberglass Tape FGT-130

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords