Packaging Tape Duck Masking Film 550mm*30m HDPE Film Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

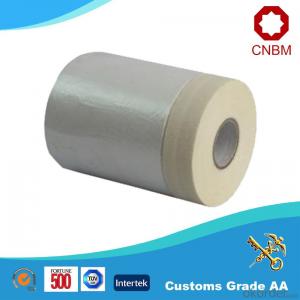

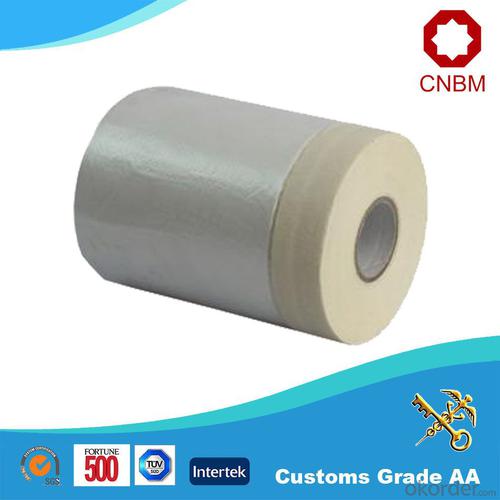

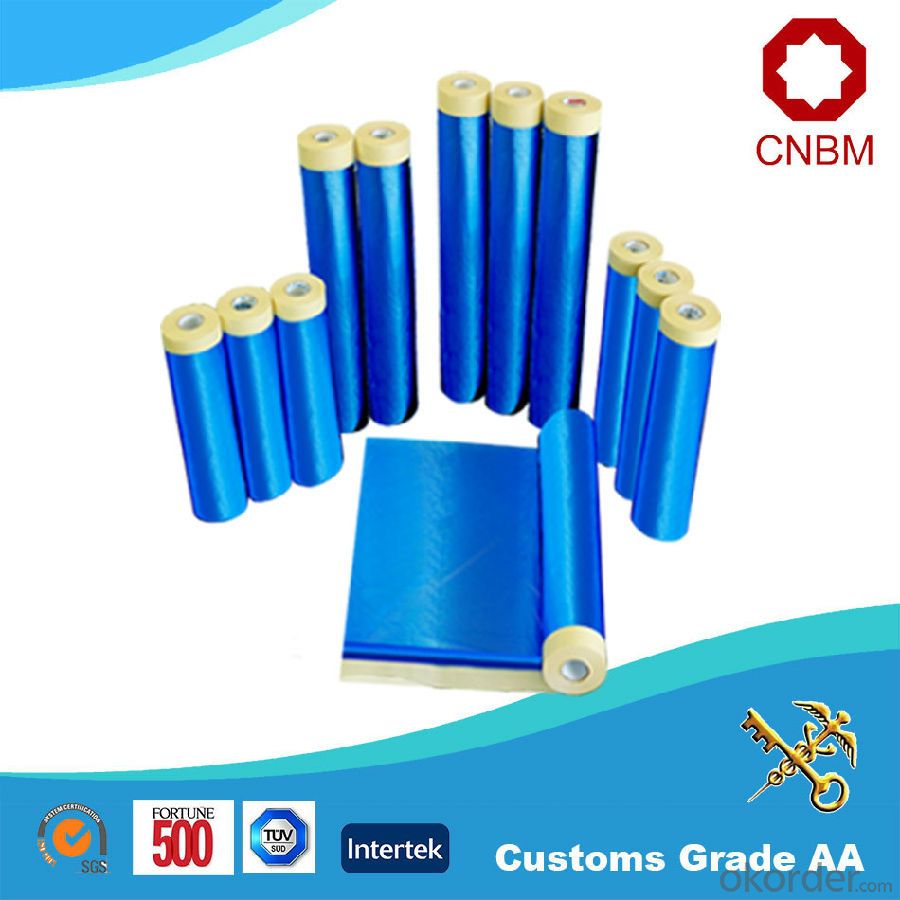

Masking Film 550mm*30m HDPE Film Made in China

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Indoor/outdoor painting

Sunlight stable even on glass

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

Q2. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can packaging tape be used for sealing automotive or vehicle parts?

- Yes, packaging tape can be used for sealing automotive or vehicle parts to some extent. However, it is not the most suitable or long-lasting solution for this purpose. Packaging tape is primarily designed for sealing cardboard boxes and other packaging materials, so its adhesive properties may not be strong enough to withstand the rigors of automotive applications. Additionally, automotive parts are often exposed to high temperatures, vibrations, and various chemicals, which can cause the packaging tape to degrade or lose its adhesion over time. Therefore, it is generally recommended to use specialized automotive sealants or adhesives that are specifically designed for sealing vehicle parts to ensure durability and optimal performance.

- Q: Can packaging tape be used for sealing foam or bubble wrap?

- Certainly! Sealing foam or bubble wrap is indeed possible with packaging tape. This type of tape is specifically engineered with a potent adhesive that effectively sticks to different surfaces, such as foam and bubble wrap. To securely seal and safeguard your belongings during transportation or storage, simply affix the packaging tape onto the edges or seams of the foam or bubble wrap. It is crucial to ensure that the tape is correctly and firmly applied to achieve a snug seal, preventing any possibility of the foam or bubble wrap coming undone.

- Q: What are the benefits of using colored packaging tape?

- There are several benefits of using colored packaging tape. Firstly, colored packaging tape allows for easy identification and organization of different items or packages. By using different colors for specific products or categories, it becomes much simpler to quickly locate and retrieve the desired items. This can be especially helpful in warehouses or storage facilities with a large volume of goods. Secondly, colored packaging tape can act as a visual indicator or warning. It can be used to highlight fragile or delicate items, ensuring that they are handled with care during shipping or transport. This can help prevent damage and reduce the risk of mishandling. Additionally, colored packaging tape can be used for branding purposes. By using tape in company colors or with a custom design, businesses can enhance their brand visibility and recognition. This can make their packages stand out amongst others and leave a lasting impression on customers. Furthermore, colored packaging tape can also serve as a security measure. Some tapes are tamper-evident, meaning that it leaves a visible mark or shows signs of tampering if someone tries to open the package. This can help protect the contents of the package and provide reassurance to both senders and recipients. Lastly, colored packaging tape can simply add a touch of aesthetics to the packaging. With a wide range of colors and designs available, businesses can choose tape that complements their branding or adds a pop of color to their packaging, making it more visually appealing. In summary, the benefits of using colored packaging tape include easy identification and organization, visual indicators for fragile items, branding opportunities, security measures, and aesthetic enhancements.

- Q: Does packaging tape come in different patterns or designs?

- Yes, packaging tape does come in different patterns and designs.

- Q: Can packaging tape be used for sealing plastic storage bags?

- Yes, packaging tape can be used for sealing plastic storage bags. It provides a strong adhesive bond that helps keep the bags securely sealed.

- Q: Can packaging tape be used for sealing construction or building materials?

- Indeed, packaging tape possesses the capability to seal construction or building materials. Although it lacks the endurance and strength found in specialized construction tapes, packaging tape can serve as a temporary or expedient remedy for sealing materials like cardboard, plastic sheets, or lightweight panels. It is suitable for fastening interim covers, affixing protective layers, or keeping materials secure throughout construction or renovation endeavors. Nevertheless, for extended or demanding applications, it is advisable to opt for tapes explicitly engineered for construction, as they exhibit superior resistance against weather, UV rays, and possess enhanced adhesive properties.

- Q: Is packaging tape suitable for sealing heavy boxes?

- Yes, packaging tape is suitable for sealing heavy boxes.

- Q: How does packaging tape perform when exposed to chemicals or solvents?

- Packaging tape typically performs well when exposed to chemicals or solvents. It is designed to be resistant to many common chemicals and solvents, ensuring that it maintains its adhesive properties and stays securely attached to the package. However, the specific performance may vary depending on the type of tape and the specific chemical or solvent involved.

- Q: Is packaging tape safe to use on mirrors?

- In general, using packaging tape on mirrors is considered safe. This tape is known for its strength and adhesive properties, which are intended to effectively hold objects in place. Nevertheless, it is crucial to consider the specific type of packaging tape being used, as it can impact the tape's safety when applied to mirrors. Opting for clear packaging tapes or tapes specially made for glass surfaces is typically the wisest choice in order to prevent any potential harm or residue on the mirror. Moreover, it is advisable to conduct a preliminary test on a small, inconspicuous area of the mirror to ensure proper adhesion and to avoid any potential damage.

- Q: Does packaging tape come in different dispenser designs for ergonomic use?

- Yes, packaging tape does come in different dispenser designs that are specifically created for ergonomic use. These designs focus on providing a comfortable grip and reducing strain on the hand and wrist during tape application.

Send your message to us

Packaging Tape Duck Masking Film 550mm*30m HDPE Film Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords