Custom Printed Duck Masking Tape, Crepe Paper Tape for Shipping Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 5000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Masking Tape Custom Printed Tape Crepe Paper Tape

1. Description of Masking Tape:

1.Carrier: Crepe Paper

2.Adhesive: Rubber

3.Standard Size: 24mm*30m,48mm*30m,0.99m*1800m,1.22*1800m etc.

4.Color: According to your request

5.Application: Widely sed for paint masking,furniture,shoe material production,automobile painting,light duty packing etc.

2. Advantages of Masking Tape

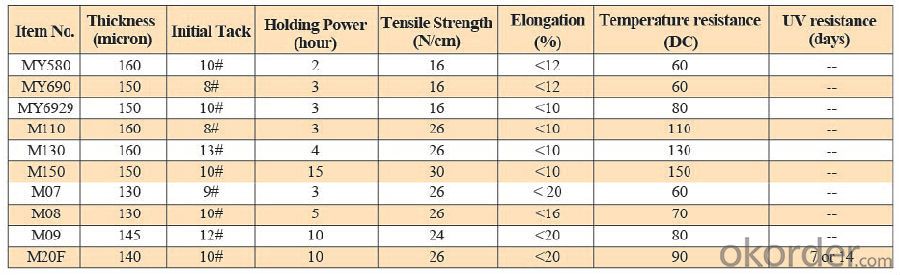

1 ) Different temperature resistance with good adhesion.

2 ) High tensile strength, good resistance of damage,no residue, eco-friendly.

3 ) Printing logo on paper core and carton mark as customers' need

4 ) SGS, ISO,BV, CTI certificates approved

5)Professional teamwork for orders

6)No.365 on the 2012 Fortune Global 500

7) Professional manufacturer with 31 years experiences of adhesive tapes

Special size,color can be made according to customer's requirement

3. Application of Masking Tape

1) Used for normal masking, such as indoor painting, car painting, car decoration painting.

2) Used in electronic industry and electric appliances for fixing and protection purposes.

3) Mainly designed for ordinary wrapping ,craftwork, lightduty masking.

4) Furniture, appliance automobile /shoes spray painting, color making, decoration and labels.

4. Details of Masking Tape

Material | Imported crepe paper coated with natural solvent rubber adhesives. |

Used | Widely used in the baking process in automobile industry, hardware industry |

Printing | Offer printing |

Color | Red, milky, green, white , yellowish, blue, black, or at will. |

Packaging | 6rolls/shrink,12rolls/shrink,72rolls/ctn,144rolls/ctn. |

MOQ | 20ft container or as you need. |

Payment terms | 30% in advance,70% balance the copy of B/L. |

Delivery time | 15workdays except the affirming date of logo on paper core and carton after receiving the deposit. |

Jumbo rolls size

| 1260mm*1800m, 1260mm*1000m |

Width | 3mm~1260mm normal width:12mm,18mm,24mm,36mm

|

Length | 10m~1800m normal length: 20m,33m,50m,100m |

Port | Shenzhen |

Certifications | ISO.9001.2008. and SGS. |

Certification:

- Q: Is packaging tape suitable for sealing heavy boxes?

- Indeed, packaging tape proves to be fitting when it comes to securing hefty boxes. Specifically engineered to offer a robust and reliable seal, packaging tape caters to boxes of varying sizes and weights. Crafted from resilient substances like polypropylene or reinforced paper, it enhances the tape's durability and guarantees its ability to withstand the weight and pressure exerted by bulky boxes. Furthermore, packaging tape commonly possesses a potent adhesive that adheres effectively to cardboard surfaces, ensuring a tight seal capable of enduring the challenges of transportation and handling. Nevertheless, it is advisable to utilize multiple strips of tape to fortify the seal on heavy boxes, thereby enhancing their security.

- Q: Can packaging tape be used for outdoor applications?

- Yes, packaging tape can be used for outdoor applications. However, it is important to choose a tape specifically designed for outdoor use, as it needs to be weather-resistant and durable to withstand various environmental conditions such as rain, sunlight, and temperature fluctuations.

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Yes, packaging tape can be used for sealing packages with jewelry or valuables. Packaging tape is designed to provide a secure and durable seal, making it an excellent choice for ensuring the safety of your valuable items during shipping or transportation. It is strong and adhesive enough to securely close the package and protect the contents inside. However, it is always recommended to take additional precautions when shipping valuable items, such as using bubble wrap or cushioning material to provide extra protection.

- Q: Can packaging tape be used for sealing PVC pipes?

- No, packaging tape should not be used for sealing PVC pipes. PVC pipes require a specific type of sealant that is designed to bond with the PVC material and create a watertight seal. Packaging tape is not designed for this purpose and may not provide a secure and durable seal. It is recommended to use PVC pipe sealant or plumber's tape specifically designed for sealing PVC pipes to ensure a proper and long-lasting seal.

- Q: Is packaging tape flammable?

- Yes, packaging tape is typically made from materials such as polypropylene or polyester, which are not highly flammable. However, it is important to note that some packaging tapes may have adhesive properties that contain flammable components. It is always best to refer to the specific packaging tape's safety data sheet or consult the manufacturer for accurate information regarding flammability.

- Q: How does packaging tape perform on non-porous surfaces?

- Packaging tape performs exceptionally well on non-porous surfaces. Its strong adhesive properties enable it to stick firmly to materials like plastic, glass, or metal, ensuring that the packaging remains securely sealed. The tape's ability to withstand different environmental conditions, such as temperature changes or moisture, further enhances its performance on non-porous surfaces.

- Q: Does packaging tape have a specific adhesive strength?

- Yes, packaging tape does have a specific adhesive strength. The adhesive strength of packaging tape refers to how well it sticks to surfaces. This strength is typically measured in ounces per inch (oz/in) or pounds per inch (lb/in). The adhesive strength of packaging tape is determined by various factors, such as the type of adhesive used, the thickness of the tape, and the quality of the backing material. Different types of packaging tape may have different adhesive strengths to cater to specific needs, such as lightweight packages or heavy-duty shipments. It is important to consider the intended use and the weight of the package when choosing packaging tape with the appropriate adhesive strength.

- Q: What are the considerations for using packaging tape on textured surfaces?

- When using packaging tape on textured surfaces, it is important to consider the adhesion and durability of the tape. The texture of the surface can affect how well the tape sticks and stays in place. It is advisable to choose a tape with strong adhesive properties that can effectively bond with the texture of the surface. Additionally, the tape should be able to withstand any movement or stress that may occur due to the textured surface. It is also crucial to ensure that the tape does not damage or leave residue on the textured surface when it is removed.

- Q: Can packaging tape be used for shipping packages internationally?

- Yes, packaging tape can be used for shipping packages internationally. It is a common and reliable adhesive used to secure packages during transit, ensuring their safety and preventing any damage.

- Q: How does packaging tape differ from masking tape?

- Packaging tape and masking tape are two different types of tapes that serve different purposes and have distinct characteristics. Packaging tape is specifically designed for sealing and securing packages or boxes. It is commonly used in shipping and packaging industries. Packaging tape is typically made from a strong and durable material, such as polypropylene or PVC, which provides excellent adhesion and resistance to tearing or splitting. It is known for its high tensile strength, which ensures that the package remains sealed during transit or storage. Packaging tape also usually has a strong adhesive that sticks well to various surfaces, including cardboard, plastics, and metals. It is available in different widths and lengths to accommodate different packaging needs. On the other hand, masking tape is primarily used in painting and DIY projects. It is made from a thinner and less durable material, such as crepe paper, and has a less aggressive adhesive compared to packaging tape. The main purpose of masking tape is to create clean, straight lines and protect surfaces from paint or other liquids during painting jobs. Masking tape can be easily applied and removed without leaving residue or causing damage to the surface. It is also known for its ability to conform to uneven surfaces, allowing for precise masking and detailing work. In summary, packaging tape is designed for secure sealing and packaging of boxes and packages, while masking tape is primarily used for painting and protecting surfaces. Packaging tape is stronger, more durable, and has a stronger adhesive, while masking tape is thinner, more flexible, and can be easily removed without leaving residue.

Send your message to us

Custom Printed Duck Masking Tape, Crepe Paper Tape for Shipping Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 5000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords