Melamine Faced Marine Plywood/Boat Woods/Film Faced Plywood for Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 21 Cubic Meter/Cubic Meters m³

- Supply Capability:

- 50000 Cubic Meter/Cubic Meters per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Marine Plywood/Boat Woods/Film Faced Plywood for Construction

| Name:Marine Plywood/Boat Woods/Film Faced Plywood for Construction | |

| Size | 1220*2440mm,1250*2500mm,915*1830mm,1500*3000mm Or as clients’ requests |

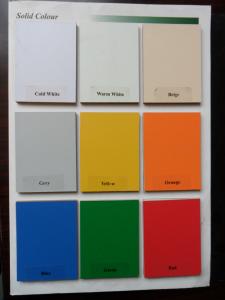

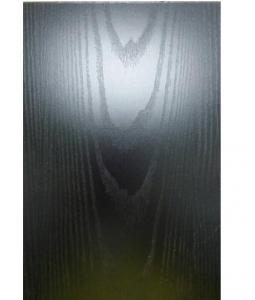

| Film | Black(domestic) film, Dynea(import)brown film ,brown(domestic)film, black(domestic) film,red film, yellow film |

| Thickness | 9mm,12mm,15mm,18mm,21mm etc; |

| Core | Poplar, Hardwood, Birch , Combi,Eucalyptus, etc; |

| Tolerance | Length/width :+/-0.2mm; Thickness: +/-0.5mm |

| Glue | MR(water proof), MELAMINE(water proof), WBP(phenolic); |

| Mositure content | 8%-12% |

| Modulus of rupture | >30MPa |

| Modulus of Elasticity | >6000MPa |

Features of Marine Plywood/Boat Woods/Film Faced Plywood for Construction

No warping, no fracture, no out of shap

2. Transference to concrete is set up very easily, so good for construction work, (there is no need for any transference preparation). it only takes the time 1/7 of the steel mould. it can shorten the project time by 30%.

3. Good to keep surface warm so in winter the project can also be continued.

4. After installation of concrete, the surface looks like a mirror. (the cement does not stick). the wall or the surface of the building can be decorated directly.

5. Can be used to make camber and it also can be cut into small pieces according the special requirements.

6. Environmentally friendly. (even after incineration, there is no hazardous substance).

7. Can be used for a long time, and for the initial price paid for the material, you will feel its value look forward to your visit and become your long term supplier.

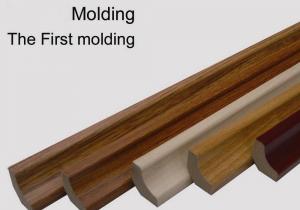

Packing---Bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6

Usage---Making construction formwork plywood, concrete formwork plywood,marine plywood etc

Delivery Time: Within 15-30 days after getting final confirmation

- Q: Do you have a solid wood paste or a solid wood paste?

- MDF can not water, water is bad. The panel is easy to skin is not good. Do you still iron paper?

- Q: What are the identification methods for the panel?

- Generally carried out in the vertical sawing or grinding method is used, are visible traces of the content.

- Q: What is the double-panel, wardrobe with this back to do it?

- Wardrobe backplane is best not to use plywood to harm too much. If you want to use a single side of the plywood. You can use Bin wood integrated board so environmentally friendly.

- Q: Plywood hot press and plywood hot press is different

- Different types of plywood have different requirements on the performance of the press: ordinary plywood, aviation plywood, plastic plywood, wood laminated plastic plate, ship plywood manufacturing requirements of the pressure in turn increased.

- Q: Will the fire board be used as a plywood for furniture?

- Yes, the fire board veneer furniture has a lot of years ago, fire board wear, fire, rich colors, decorative effect is good.

- Q: What is a stone trim? Home stone panel okay?

- We all know what is the stone, in recent years, with the development of the times, the improvement of living standards, stone industry is also advancing with the times, in the constant high quality of life close to the variety of stone variety, Making the use of slowly in the decoration of the stone more and more common, and gradually become a trend of the trend.

- Q: What is the thickness of the trim panel?

- The thickness of the panel is usually 3mm, but there are some other thickness of 0.9mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.7mm / 3.0mm, 3.6mm, etc., the thicker the better the performance, The more true, the more clear texture, bright color saturation is good.

- Q: Double-sided eco-board with what adhesive stickers

- Of course, is a dedicated glue, and the best to buy you double-sided eco-board panels, there should be supporting it

- Q: Wooden door surface panels (multi-layer board) is a solid wood door or solid wood composite door?

- According to the solid wood doors are not posted, solid wood doors of the process is generally refers to the section, or pure wood.

- Q: The difference between eco-board and blockboard

- The generalized eco-board is equivalent to the melamine plywood, its full name is melamine impregnated film paper facing wood-based panel, is to have different colors or textures of paper into the eco-board resin adhesive soak, and then dry to a certain degree of curing The pavement in the particleboard, moisture board, medium density fiberboard, plywood, blockboard or other hard fiber board surface, made by hot pressing plate.

Send your message to us

Melamine Faced Marine Plywood/Boat Woods/Film Faced Plywood for Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 21 Cubic Meter/Cubic Meters m³

- Supply Capability:

- 50000 Cubic Meter/Cubic Meters per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords