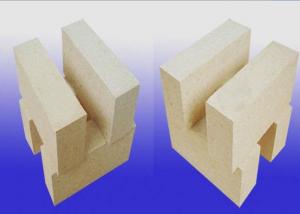

Manufacturer of Column Head Mould-3

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 50000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Column Head Mould:

Our Column Head Mould has the function of fireproof, mildew & worm resistant, moisture proof, sound & heat insulated.

We select the A-class gypsum powder (mineral purity =93-95%, crystal water T =18%, edible) whose main ingredient is the calcium sulfate hemi hydrate (CaSO4.1/2 H2O). The special powder contains no chemical materials with high whiteness & purity.

Specifications of Column Head Mould:

We can offer Mould for Roman Column Head products, diameter size: 300MM 350MM 400MM 450MM 500MM 550MM 600MM. Other sizes can be customized according to customer requirements.

- Q: I've bought a rubber cement today and it was pretty fine when I bought it. Then when I was about to use it, it was very very thick, I mean, to the point where it is not spreadeable (lol idk if that word exists).What can I do to make it smooth again?(Sorry about my english)

- Nothing wrong with your English... Look on the can/bottle see what solvent was used to make it. You should find something like acetone, hexane, heptane, benzene or possibly something else. After you've determined what the solvent is, call some art supply stores see if they carry that solvent. The solvents in rubber cements evaporate very rapidly, so you should keep the lid tightly closed until ready to use, then put the lid back on tight. Good luck...

- Q: The fence is typical 47 inch wire field fencing. I am putting it on a one acre lot with the post being placed every 15 feet. I am using landscaping post as they are cheaper then regular post and i have worked with them before on my stockade fencing with no problem. I am installing two 10 foot farm gates which are 1 and 3/4 inch tubular steel. I will be using 4x4 pressure treated post on the 4 corners and the post holding the gates.I need to know how much concrete i would need for the 60 land scaping post and the 6 4x4 post. I am figuring one 60 pound bag of cement (the kind you get for about $2.50 a bag) for every two landscaping post and one full bag for each of the 4x4 post giving me a total of 36 bags. I am presently not planning on adding any stones to the mix, just water.The post will be 2 feet in the ground and 6 feet above. Barb wire across the top.Does this sound right or am way off on how many post will do one bag? The total feet of fencing is 900 feet.

- Cement is good, but we like to use crushed stone on all our fences that we install (if it is wood). Reason being, the crushed stone allows the water to drain away from the wood and you get less rot over the course of time than you would with cement. Also, once you set the post in cement, it is a royal pain to remove/adjust. Not to mention the ease of having buckets of crushed stone instead of having to mix cement and all the hastle which goes along with that. just a thought

- Q: I have some cement cracks and i was wondering how to fix it. any sugsetions?

- You didn't say if the where vertical or horizontal. The best way is to clean the crack out and use either a vinyl cement or hydraulic cement. Both can be found at a Menard's or other local hardware store.

- Q: Final setting time of cement...?

- First is the 1st 24 hrs which then you can walk on the slab. 2nd is the next 7/8 days after which you could drive across and the final setting time is the next 30 days for the slab to cure. GL

- Q: The factory was established this month, not yet officially produced, is now renovated workshop. More

- Can be divided into three categories: machine materials, inorganic materials (metal, non-metallic), composite materials.

- Q: WHATS THE DIFEREANCE BETWEEN CEMENT, AND CONCRETE?

- Cement is the powder made from limestone, clay and gypsum that is the binder for making concrete. Concrete is the product of mixing cement with sand and/or gravel and water. Sidewalks, bridges and buildings are concrete, not cement.

- Q: what is the best cement to fix cracks on cool decking

- You can buy cartridges of cement like stuff for small cracks. When you say cool decking do you mean temperature or style. I'm assuming temperature. If the cracks are bigger you can get premixed in buckets. What is the best? Cement is cement any crack you fill will have to be refilled. New cement does not stick well to old dry cement. They do make plastic fillers, my landscaper used it for grout in the patio, that has held up real well over the years. You may want to try that. Got to Lowes or HD and talk to the people there for details.

- Q: I spent ?800 on this and am really worried that this is wasted (the use by date on the paper wrapping is october 2008. I have opened one of the bags and there is still powder in it however there are hard bits. Is there anything i can now do with this cement? The builders start mid may. thanks

- Toss it, it's no longer any good. Even if you break up the clumps the end product will crack over time. Not worth trying to skimp here.

- Q: We are painting our living room floor. My husband wanted me to buy a BEHR cement paint stain at Home Depot. However, they didn't have the colors we wanted available in that paint, so they told me that the BEHR Porch and Floor paint was exactly the same (the stain just has the option of semi-translucent colors, whereas the other does not) and they had a better variety of colors. I trusted the people, but have I made a big mistake, what is the difference? I'm nervous my husband will be very upset when he gets home, since it is non-refundable.

- this could be a job you desire to do perfect the 1st time. i could advise an epoxy product. it is going to fee some money however the fee is very well worth the outcomes and the added sturdiness. Spend it slow with the instructions paying particular interest to the section on concrete guidance. you'll be able to might desire to etch the floor and it could be easily freed from all previous wax, paint, sealers and so on. right here i bypass lower back telling you too plenty. different products have different guidance techniques. in basic terms persist with the instructions religiously. The producer is accustomed to how the product will artwork suitable. a high quality paint, utilized properly to an ideal arranged floor, ought to be remarkable. I easily have some very previous paint on my front porch that became utilized properly and that i won't be able to blast it off with a commercial rigidity washer. BTW, a number of the products you'll be able to desire to pick between grant glitter, flickers, and different issues to gown up the visual attraction of the finished floor. Traction improving brokers are additionally obtainable for some products, they are able to bypass a protracted way in the direction of combating falls. do no longer forget approximately to stay out of the corners, the stuff i'm suggesting will take hours to an afternoon or greater to treatment nicely adequate to stroll on. in case you paint your self right into a corner you would be there for a mutually as...

- Q: What kind of drill do I need to easily drill holes into the cement sub-floor of my house (for a flooring project)? I've already tried two different types of masonry bits with my cordless, 18 volt Bosch (model 3850). I'm thinking that the bit isn't the problem, it's the drill. It takes about 10 minutes and a way too much effort just to drill one hole. Any suggestions?

- I would go to a rental store and rent a SDS drill these drills are designed to drill concrete and will drill a 1/4x6 hole in about 30 sec.You will also need to get the appropriate sds drill bit . Also when you drill concrete drill a 1/2 then pull up on the bit then drill again and so on this will save your bits and drill faster the action helps the bit pull the concrete out of the hole. The rental for a sds drill in my area is 20-25 bucks a a day.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2006 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacturer of Column Head Mould-3

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 50000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords