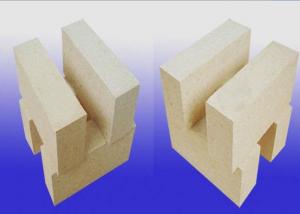

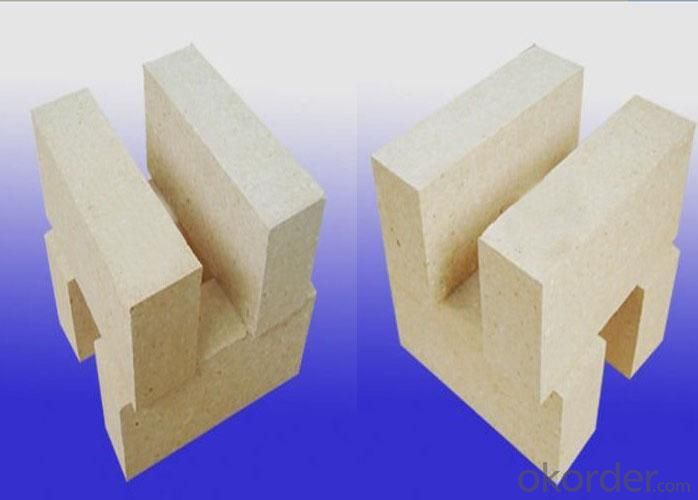

Refractory AKZ-85 Alumina Bubble Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month alumina bubble brick in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Refractory AKZ-85 Alumina Bubble Brick

1.High compressive strength

2.Excellent thermal shock resistance

3.High thermal efficiency of the kiln

Description of Refractory AKZ-85 Alumina Bubble Brick

alumina bubble brick refractory brick bricks have high-alumina bauxite powder and refractory clay as raw materials and some inflammable additions, shaped by tamping or extrusion pressing and fired in high-temp tunnel kiln after being dried.

alumina bubble brick refractory bricks have three brands in accordance with their bulk densities, which are decided by the amount of the inflammable additions. alumina bubble brick refractory bricks with large bulk density have the features of high mechanical strength and small change of load at a high temperature.

Used alumina bubble brick Features

·High compressive strength

·Excellent thermal shock resistance

·Able to lower the heat capacity of the furnace wall

·High thermal efficiency of the kiln

·All types of products available as customers require.

Application of alumina bubble brick

alumina bubble brick can be Used in heat-insulating layers and furnace linings of thermal equipment, such as, roller kilns ceramics, heating furnaces petrochemical reforming, reforming furnaces, soaking ptis metallurgy and blast furnaces.

Physical and chemical index of Refractory AKZ-85 Alumina Bubble Brick

Item | AKZ-85 | AKZ-90 | AKZ-99 | |

Chemical composition | Al2O3 | ≥85 | ≥90 | ≥99 |

SiO2 | ≤13 | ≤8 | ≤0.2 | |

Fe2O3 | ≤0.5 | ≤0.5 | ≤0.5 | |

Apparent Porosity% | 58-62 | 58-62 | 58-62 | |

Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 | |

Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 | |

0.1Mpa Refractoriness Under Load T0.6 °C | ≥1650 | ≥1700 | ≥1700 | |

Permanent Linear Change On Reheating

(%)1500°CX2h | ±0.3 | ±0.3 | ±0.3 | |

20-1300°C Thermal Expansion % (x 10-6) | 0-7.8 | 0-8.0 | 0-8.6 | |

Thermal Conductivity(Average 800°C) W/(M.K) | ≤0.8 | ≤1.3 | ≤1.5 | |

Max Service Temperature °C | 1680 | 1700 | 1800 | |

- Q: why does cement not become soft when wet after it has dried?

- Cement is a chemical reaction with water. The water only makes it feel wet when yo are first mixing it. But the water is actually reacting with the calcium oxide in the cement powder which turns rock hard after the reaction takes places.

- Q: and what is their #Basically, in out rental house, it looks like the guy dumped a bucket of motor oil on the garage floor and then used the oil to paint a section of the floor. And his car dripped everywhere on the other half of the garage. So now the while garage has drips of oil everywhere and looks kind of like the black parts of this freeway. And to make matters worse, it is totally soaked in to the cement.

- if you want to clean it your self youneed to sprinkel tide soap all over the oil areas when it starts soaking the oil in the soap take a plactic brush and brush the soap around till the soap is dark then sweep it off and do the same process only with the soap a little wet with water kinda pasty with the plactic brush then rinse with a hose if possable when it is dry the oil will be gone, hope this helps.

- Q: When i buy it from a cement supply house they charge me sales tax but when i buy it from home depot or lowes they dont. My accountant told me to be careful since i am responsible for paying my taxes.

- Yes. Everything gets taxed. Are you sure Home Depot or Lowes don't charge you tax at the register? That's odd if they don't.

- Q: I was wondering if bees can go through cement?Like a cement wall or something.I've heard they can go through wood.

- No bee's can not go through cement. Actually I don't think they can go through wood unless there is a space or hole where they can enter.

- Q: Tableware kitchen, epoxy resin can? Specific paint name and processing process, thanks for the

- The cement board is prefabricated and also cast

- Q: I'm wanting to get the quot;DIY Belgian-Style Stone Moldquot; by Pathmate to create a back yard area for my husband and I to enjoy the out doors some. One of the things I'm was wanting to do is to have all the concrete stones be a nice dark blue color so it would look good with the house and any outside furniture. I really don't want to just apply a coat of paint the surface of the stones. And i did read somewhere online that I could mix latex paint with water and concrete but i cant find any photos with the results. any suggestions? I do want this project to be as inexpensive as possible please help

- Maybe you could ask a concrete company close to you if you could buy a small amount of color pigment. They have charts there so you can see the colors and I am sure since you don't need that much for your project (it is not a whole driveway) they might sell you some. Ths way you know how it would look and that it works with concrete.

- Q: It has a strong taste and smell. Sometimes it smells like smoke.

- Dental cement is not toxic. It has cloves in it which acts as a soothing agent. Maybe that's the smell and taste your noticing.

- Q: How much cement is left in the U.S.?

- Cement is not a raw material, it's something manufactured and there are huge amounts of the raw materials (clay, limestone) that go into it.

- Q: How a cement solution is prepared;;what is effect of quick setting of cement;;?

- cement is an ingredient in concrete. It sets with the chemical reaction of Calcium carbonate (limestone) and water to form a hard substance.

- Q: I have a small very detailed cement dog which got really muddy. I have tried scrubbing it with a brush and warm water, but it still has a brown color that wasn't there before. I am afraid to use anything too harsh for fear of destroying some of the detail wrok.

- A small amout of Mr.Clean or any cleaning agent shouldn't do any harm.Use warm water and a soft brush or sponge. Rinse well and let dry. I had a little cement donkey I used to clean this way.

1. Manufacturer Overview

| Location | Henan,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe |

| Company Certifications | business license |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,Qingdao,Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Refractory AKZ-85 Alumina Bubble Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month alumina bubble brick in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords