High quality borosilicate 3.3 tempered heat-resistant glass(Semiconductor chip)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High quality borosilicate 3.3 tempered heat-resistant glass(Semiconductor chip)

Product Introduction

The main characteristics of high borosilicate glass 3.3 are: no peeling, non-toxic, tasteless; Good transparency, clean and beautiful appearance, good barrier, breathable, high borosilicate glass material, has the advantages of high temperature resistance, freezing resistance, pressure resistance, cleaning resistance, not only can be high temperature bacteria, can also be stored at low temperature. High borosilicate glass is also known as hard glass, is an advanced process made of processing.

This revolutionary glass is made of borosilicate, a special material that combines strength and durability with an extraordinarily high heat resistance.

Whether it's functional or decorative, this magnificent material will make any project look great while helping protect against extreme temperatures up to 500°C (932°F). And because of its excellent thermal shock properties, it won't cloud over time from frequent temperature fluctuations either!

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

Feature

Low expansion coefficient

good thermal properties

mechanical properties

optical properties and ultra-high chemical stability

Advantages

Fire protection duration exceeding 2 hours

Outstanding mechanical strength, 8-10 times stronger than ordinary glass

Small specific gravity, more than 8% lighter than ordinary soda lime silica glass

Higher light transmittance

Stable chemical property

Without self-explosion

Excellent ability at thermal shack

When it comes to the use of borosilicate glass semiconductor chip technology, there are many advantages to this material over traditional silicon-based chips.

1.borosilicate can handle higher temperatures without its properties becoming affected by heat or pressure changes like silicon would when exposed to extreme conditions. (This makes them ideal for high-temperature electronics as well as other products requiring precise temperature control—such as certain types of lasers or x-ray machines where accuracy needs to be paramount due to the potentially dangerous nature of the radiation they emit if not properly contained within their housing materials)

2.Borosilicate's remarkable strength means that these chips can be made much thinner than those using silicon wafers – a major plus for any device needing miniaturization capabilities such as smartphones or tablets with very limited space inside them for components like processors or memory modules which require large amounts power yet have low volume requirements at the same time . Additionally , because these materials don't suffer from oxidation (rusting) like metal parts do , they're perfect for long-term reliability in harsh environments where exposure could lead regular metals corroding away over time.

3. Borosilicates' excellent electrical insulation properties make them great candidates for complex circuitry designs where insulation between each layer is essential in order prevent short circuits occurring during operation – something that’s especially important when dealing with high voltages which could cause irreversible damage if allowed unchecked currents flowing through sensitive areas on board . All this combines together making borosilicate glass 3.3 an exceptionally suitable solution whenever needing highly durable materials performing reliably under extreme conditions while providing exceptional electrical isolation.

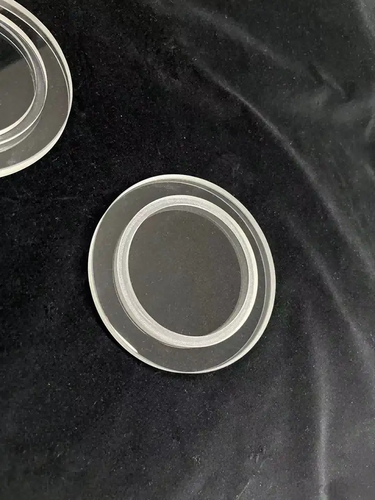

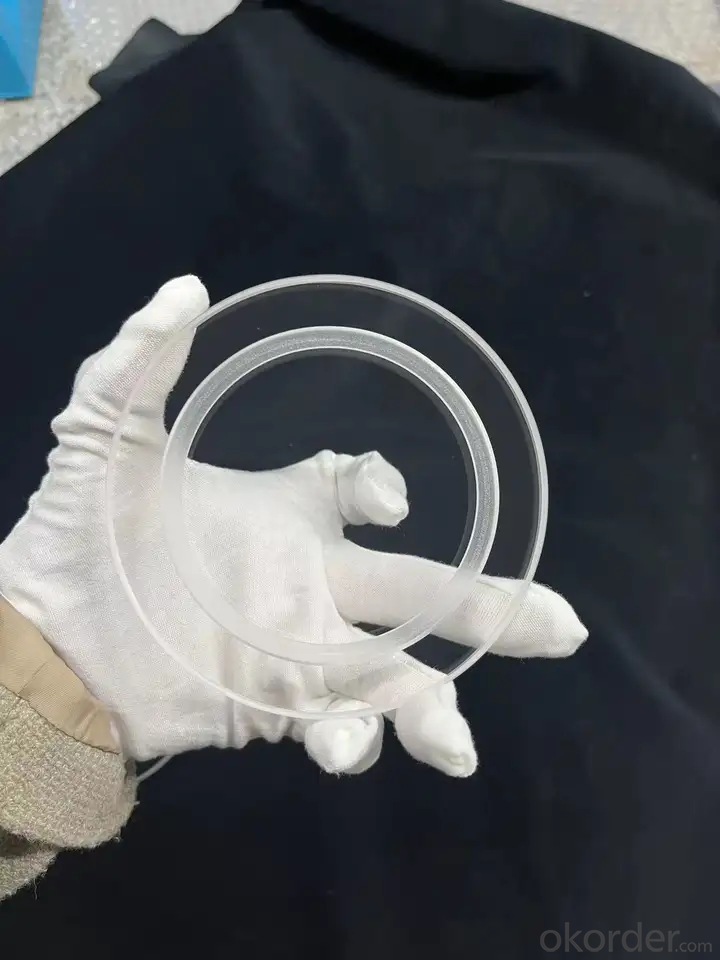

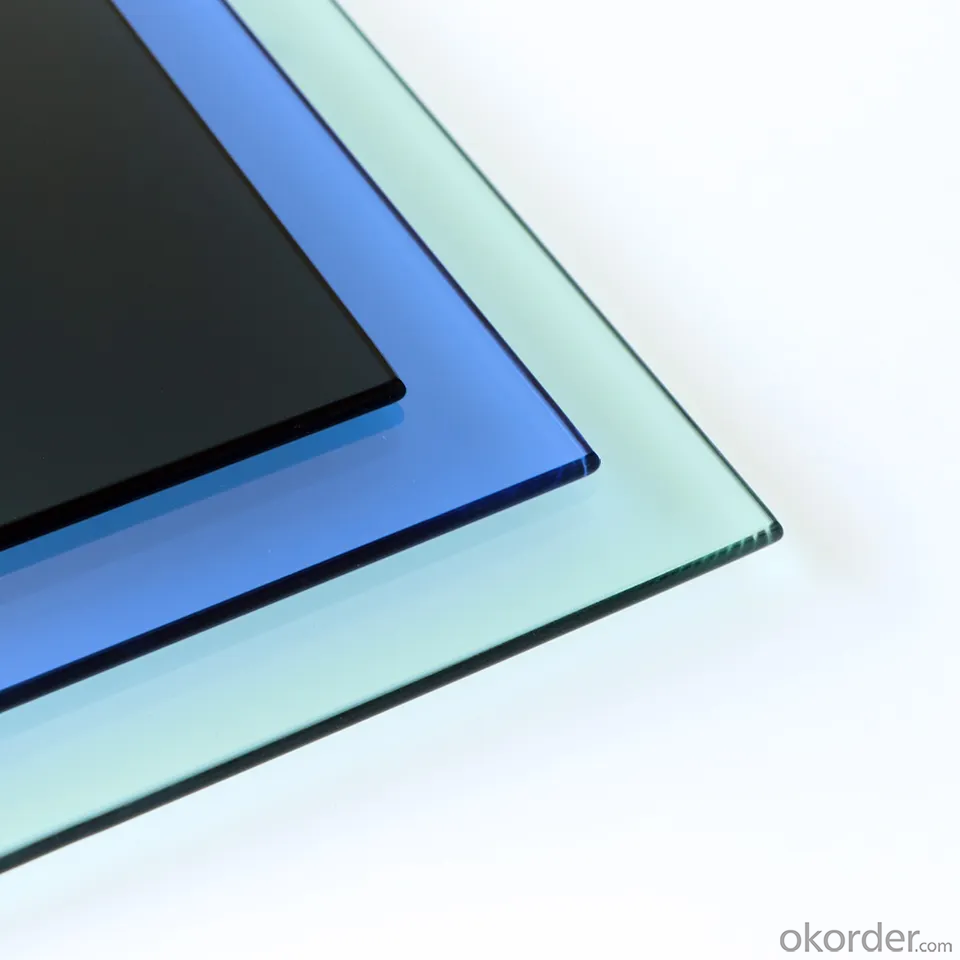

Packaging Photos of Borosilicate Glass 3.3

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Decoration decoration materials, fire performance in line with the technical standards of fire how to apply for documents?

- Decoration is a relatively laborious things, but also a science, the proposed spirit of "heavy decoration, light decoration" to decorate the principle, do not move the decorative and modeling. Plate and paint materials, the focus is whether the environmental protection is qualified, the quality of the guarantee can go to the regular supermarket procurement. Hydropower materials sloppy, should use brand products, such as Philips, Akihabara line; Weixing, love Hong pipe and so on. There are many styles of sanitary ware, which should be purchased according to the interior design requirements. With the rise in prices, the cost of renovation is gradually increasing, in the house to spend most of the savings, the decoration has become a burden of many people. Therefore, how to save money to become a lot of people want to know the secret. In fact, the decoration is not so difficult to save money, only to master the right way, spend the least money can also be loaded with satisfactory results.

- Q: What is the thickness of the thin fire retardant paint brushing each time?

- Thin-type fire-resistant paint brushing or spraying the thickness of each 0.5-2mm, according to the nature of the material to determine the thickness. Thin fire retardant coating if it is the kind of wear and tear that the amount of more than the burden of consumption in Russia with the same thickness of the spray between the 1-1.5mm appropriate. Wait until the coating is dry and spray the next time, the thickness of the coating is not sag as the standard. First, the construction method 1, before the construction of steel surface to be rust treatment, and remove the surface dust, oil, spray 1 to 2 times the anti-rust paint. 2, with a bucket spray device with 0.4-0.6Mpa air pressure spray, paint to be evenly stirred. 3, pay attention to the first coating coating thickness of 1mm or so, dry and spray the second time, the coating thickness of 2mm, after drying spray the next time, and so on until the corresponding coating thickness. 4, according to the requirements of the fire limit level, spray to the appropriate coating thickness. 5, when the surface requirements of smooth and smooth, should be applied to the last side of the spray for smoothing. Third, the note 1, the coating can not be mixed with oily paint in the wet state. 2, the construction temperature should be above 0 ℃, rain or surface condensation or air humidity more than 85% when the construction should not be. 4, the paint is not combustible, not fried, non-dangerous goods, all kinds of transport can be transported.

- Q: Is the material inside the fire door gypsum board?

- No, it is fire board (perlite).

- Q: How is the distinction between fire grade?

- How is the distinction between fire grade?...

- Q: Short point is to do hand copy

- Several common fire fighting methods: 1, furniture, bedding and other fire: the general use of water fire. With water around the items such as the basin and so on to the flame on the water, but also the water pipe connected to the faucet sprinkler fire; at the same time the burning point near the combustible humidification. But the oil, electrical fire can not use water to fire. 2, electrical fire: household appliances or lines on fire, we must first cut off the power, and then dry powder or gas fire extinguisher, can not directly splash water to prevent electric shock or electrical explosion wounding. 3, the TV fire: TV in case of fire, never water, you can cut off the power, with a quilt to cover it. Fire, only from the side close to the TV, to prevent the camera tube explosion wounding. If the use of fire extinguishers fire, should not be directed to the TV screen, so as to avoid the sudden cold after the heat and explosion. 4, the pan fire: the oil pan should quickly shut down the stove gas valve, directly cover the lid or cover with a wet cloth, but also to the pot put the chopped vegetables to cool the fire, the pot smooth from the fire, After cooling to open the lid, do not pour water to the oil pan. 5, gas tank fire: use wet bedding, clothing and other cover fire, and quickly close the valve. 6, the body of the fire, do not run around, can be used to roll or heavy clothing to suppress the flames. Wearing a wet towel, handkerchief and so cover your nose and mouth, try to make the body close to the ground, bending or creeping forward.

- Q: Fire protection requirements for indoor ceiling materials

- In all the interior decoration of the fire design, the ceiling of the fire design in the most important position. This is because the fire is burning up the fire, the ceiling first and directly accept the fire test; the same time, there is a direct impact on the evacuation, will directly constitute a threat to the safety of evacuated personnel. Therefore, in the interior ceiling decoration design, should give full consideration to its fire problem. "Fire protection within the building design fire code" on the different civil buildings of indoor ceiling material fire performance has a detailed requirement. Ceiling (prungroof), refers to the roof of the living environment of the decoration. The ceiling is an important sub-division of the building decoration project. The ceiling has the function of insulation, insulation, sound insulation and sound absorption. It is also a hidden layer of electrical, ventilation and air conditioning, communication and fire prevention, alarm pipeline equipment and so on. The ceiling in the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q: Rubber insulation material fire it?

- B1 grade is flame retardant material, B2 grade is combustible material. Must be required random sampling, to reach the oxygen index 40 have the opportunity to fire. A music torn, Owen and Fu Rui Ge can

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability rating, that is, the material has or the material has been treated with a postponement of the nature of the flame spread, and the division of the system. 1, the plastic flame retardant grade from HB, V-2, V-1 to V-0 step by step increase: HB: UL94 and CSAC22.2No0.17 standard in the bottom of the flame retardant grade, requiring for 3 to 13 mm thick Sample, burning speed less than 40 mm per minute; less than 3 mm thick sample, burning speed less than 70 mm per minute; or 100 mm mark before extinguishing. V-2: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. There can be a burning thing falling. V-1: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. Can not have a burning thing falling. V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds. Can not have a burning thing falling. 2, UL classification of plastic material burning grade? UL is the plastic material standard test piece after the flame burning after the spontaneous combustion time, spontaneous combustion speed, falling particles to determine the state of the burning of plastic materials, according to the level of good and bad, followed by HB, V2, V1, V0, 5V, There are very thin material grades VTM-0, VTM-1, VTM-2, and foam material grades HBF, HF-1, HF-2.

- Q: Is the soundproof cotton a fireproof material?

- Can be sure that it is not! Flame retardant ≠ fire.

- Q: What are the fireproof materials for Class A roof insulation?

- At present, only phenolic board can meet the requirements, the test temperature of 2000 degrees, no droplets, good integrity. The thermal conductivity of non-combustible, non-toxic, smoke-free!

Send your message to us

High quality borosilicate 3.3 tempered heat-resistant glass(Semiconductor chip)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches