Manufacture of GFR Fiber

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of GFR Fiber

Properties of GFR Fiber:

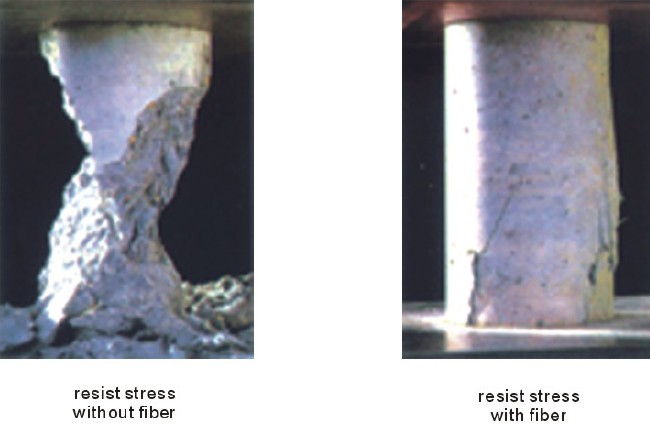

It has excellent properties with alkali resistance, stiffness, bundle – state, ageing – proof, Mixed 20 minutes in cement at 50rpm,it can still keep good bundle state, it won’t dispersed to filament.

Purpose of GFR Fiber:

It is a high integrity AR Glass Fiber Chopped Strands designed for use in the reinforcement of concrete, renders and mortars. It may be added to conventional mixes either on site or by prepending with other dry mix components. The low – tex strands permits efficient reinforcement at low dosages. They are particularly suited to the modification of standard concrete mixes for floor screeds and slabs,and for the preparation of prebagged mixes of special mortars and renders.

(2) Water – dispersed Fiberglass Chopped Strands

Properties of GFR Fiber:

AR Glassfiber Applied with water – dispersed size, the strands will disperse well to filaments in water in 10 seconds, and also disperse fast, usage amount less, enlarge strength.

Purpose of GFR Fiber:

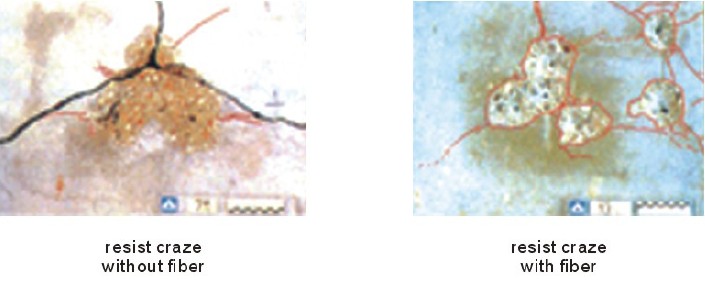

It is typically used at a low level of addition to prevent cracking and improve the performance of ready mix concrete, floor screeds, renders or the special mortar mixes.it can be used for surface crack – proof of GRC products.

Applications of GFR Fiber:

Applying for Fiberglass Reinforced Cement/Concrete.Alkali resistant, excellent integrated with cement,dispersibility.

Specification of GFR Fiber:

Code |

Length(mm) |

Diameter(um) |

Compatibility |

Applying Process |

LOI % |

Moisture Content % |

G1 |

6/12/20/24/30 |

13 |

Cement/Concrete |

Premixed/Water-dispersed |

1.3-1.6 |

<=0.2 |

Feature of GFR Fiber:

AR (Zro2 14.5% or 16.5%) chopped strand used to prevent crack of GRC components

Good Integrity and no static electricity

Low Fuzz

Excellent integrated with cement

Good filament flexible and magnificent strands distribution cement

Endued good physical and chemical properties for GRC

Disperse Fast

Low Dosages

Harmless

Application of GFR Fiber:

--Mix your resin and hardener, or catalyst

--Next add your AR Fiberglass Chopped Strands

--It is best to use a paint mixer on your power drill to ensure that all of the strands are properly saturated

Thick layers and large pour areas can create excessive heat, so proceed with caution.

Package of GFR Fiber:

AR Fiberglass Chopped Strand packed in Kraft bag, 20 kg per bag,39 bags per pallet, the net weight will be 780kg per pallet. Then 20 pallets in a 20 feet container, The totally net weight is 15.6 ton.

Warning :

Fiberglass Chopped Strand can cause eye irritation, harmful if inhaled, may cause skin irritation, harmful if swallowed

Avoid contact with eyes, and contact with skin, Wear goggles and face shield when handing. Always wear an approved respirator. Use only with adequate ventilation. Keep away from heat. Spark and flame. Store handle and use in a manner that minimizes dust generation

- Q: i need help hopefully someone can answer before wensday

- A cement is a binder, a substance that sets and hardens independently, and can bind other materials together. it was made from crushed rock with burnt lime as binder. Cement (as in Portland type cements) is made by heating limestone to 1450 degrees C, then grinding the result into fine powder and adding a small amount of clay. When mixed with sand, stones, or other aggregates, the result is concrete. Cement hardens by hydration, absorption of water, and not by drying. Chemical Formula for cement i think its 3CaO SiO2 Go to this link... this may help you to find you a better answer elearning.vtu.ac.in/Programme%2016/ENotes/ConcreteTechnology/Unit1-RVR/Unit1-L2-RVR.pdf

- Q: (in pounds)

- I think there needs to be more data. For example, how much volume does one pound of cement fill....or something like that in order to complete the equation.

- Q: What is the recommended width left between each tile for grouting and do you recommend putting felt asphalt between wall and cement board?thank you for help

- 12x12 tiles would have an 1/8 grout line.Look for the yellow boards(like sheet-rock,have a bright to dark yellow color)for the showers,these are moisture/mold resistant.Normally,4 square tiles are used and have a 3/16 grout line.Mastic and a 1/4 notched trowel.Rubber grout trowel and grout sponge with a bucket of water,change the water a few times.Don't let the grout dry completely before sponging excess grout off tiles,should have a thin clean grout lines.

- Q: How do you pronounce cement?

- Suh-ment

- Q: I would like to ask: inside the building materials, often mentioned water-based products, cement-based products What is the meaning? You prawn help solve ~ ~ ~! The The 3Q more

- Cement-based products to cement as the main cement material of building materials products

- Q: why is cement still very high when everything is going down?

- the word cartel is not only limited to the cement industry. controlling any business operations/industry in the Phils is way too common. how's this; illegal drugs either supply, distribution and production gambling any forms rice sugar coconut hiring of overseas workers the so called smoke belching testing the so called drug testing for driver's license application you name it the Phils have it. group of people have master the art of controlling businesses apparently these cartels are HUGE fund supporters for any politicians seeking public office. Now how will this end? don't know! God save the Phils! G'Day

- Q: I know it's mostly different names for the same thing, but there must be some differences. It might have something to do with adding sand and/or rocks to make a mixture, but I'm not sure.

- Your all wrong! Cement and sand and or gravel when mixed in a proprtion of 1-2-3, in that order, and water is added, becomes concrete when it hardens. Mortar, normally used to lay up large stones, brick, concrete block and the like, is cement with lime added, and sand, in a mix of 1-2, and water. The lime in the cement makes the mortar sticky so it adheres to what it is mortaring.

- Q: I'm looking for a place to buy white portland cement, in small amounts, like around 100-200 pounds. I've looked at all the local hardware stores and can't seem to find anything but grey and I need white. thanks

- White Portland Cement

- Q: Who likes the smell of fresh cement?

- Fresh cement, and fresh-cut lumber, and putty. I'm a sucker for building supplies and construction sites.

- Q: i want to practice track on the streets and i want to break in track shoes with spikes

- no you really shouldn't, i suppose you could but one it wears them down, two it feels weird and you cant run as well. use them on a track or grass/dirt roads

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacture of GFR Fiber

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords