Manhole Cover Fonte Ductile Iron C250 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Cast Iron Manhole Cover Description :

A manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthorized persons and material.

A manhole cover sits on metal base, with a smaller inset rim which fits the cover. The base and cover are sometimes called "castings", because they are usually made by a casting process, typically sand-casting techniques.

2.Main Features of the Ductile Iron Manhole Cover:

Designed structure & pressure dispersion

Arc-shaped bottom structure allows the pressure they bear disperse averagely on the whole surface. Besides, the products are made not by SMC, it was put in several layers of fiber cloth to enhance the structures. So they are stronger than SMC composite manhole covers.

Consequences of temporarily overloading

Temporarily overloading may cause smash of concrete covers, seriously deformation, even slightly split. But this will not happen to FRP fiber cloth manhole cover.

Safety options

There is no metal contain, directly reducing potential accident or further maintenance costs caused by thieves. Anti-slip surface offer a safe road condition even in extreme weather.

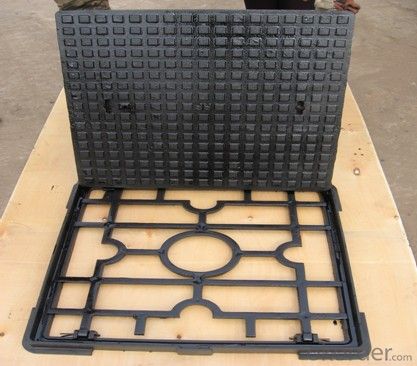

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) Production information

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

2) Material

A) Ductile iron GGG50

B) Grey iron GG20

3) Designs

A) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

B) as per customers' drawing or samples

4) Process

A) Molding boards

B) Hand Casting

5) Coating

A) black bitumen or epoxy .

B)Coating as per customer's requirement

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. I’ve measured my clear opening size but none of your covers match it, can you offer anything?

A. It’s likely that your cover is quite old and in imperial measurements which are no longer manufactured. However, we can offer bespoke solutions with manhole covers made to the specification you require.

Q. The project I’m working on requires a manhole cover with a quality finish, what’s available?

A. Naturally, galvanised steel of black polypropylene aren’t always ideal, and so we offer brass or stainless steel edging, as well as complete stainless steel covers.

- Q: What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- 2 improve the crystal structure, enhance the formation and stability of spherical carbon crystal;Forgings are generally stress bearing members, and most of them are made of high strength medium carbon steel (alloy), which is formed by forging and fine crystalline. After the shell is annealed or quenched and tempered, the mechanical properties of the shell are more superior, and it has better strength and better elasticity;Welding materials.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- This is difficult to say, the key is to see the specific parts and components, the final mechanical performance requirements.For example, gray cast iron, usually graphite annealing, to heat treatment annealing, surface quenching and so on, ductile iron can be a variety of annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical treatment and so on, in a word, heat treatment of steel can usually, nodular cast iron can do. Malleable cast iron and vermicular cast iron are often subjected to graphitization annealing and stress relieving annealing, while wear-resistant cast irons often undergo quenching + low temperature tempering, and so on.Welding is the case, such as bearing steel welding must be quenched + low temperature tempering, machine spindle welding (repair welding) must be quenched and tempered treatment, and so on. Of course, if it is a general weld, there is no need for heat treatment or, at most, stress relieving annealing.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The molten iron (molten iron, scrap steel, scrap casting, iron alloy) is melted into cast iron by means of an electric furnace or cupola, and is poured into a casting.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- Tangshan Yongding automobile spare parts factory also give a lot of supply, casting factory of Tangshan n to the car enterprises casting wheel gearbox etc.The team of casting experts welcome you to ask questions and accept questions!

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

Send your message to us

Manhole Cover Fonte Ductile Iron C250 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords