Made in China Plastic Reusable Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic formwork

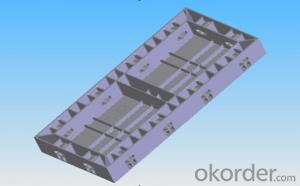

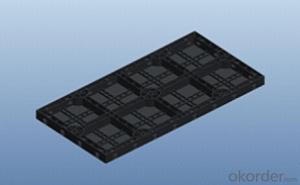

Made in China Plastic Reusable Formwork

Saving your time, money and energy !!!

The material of modular formwork is ABS mixied with special glass fibres which enable panels to hold high pressures.

The handles are made by high strength Nilon, each panel locked by at least 5 handls, which makes the whole system strong enough to pour 40cm walls.

What is Details of our products plastic concrete formwork ?

Features:

1. Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times,

where Plywood can only be reused 3 to 5 times. Therefore the Plastic Formwork

is more cost effective.

2. Waterproof -- As the nature of plastic material. It's imputrescible and rustless,

especially suitable for underground and watery circumstance.

3. Interlocking Design -- No release agent needed, good effect of demolding.

4. Easy deassembly -- The template will be separated easily from concrete

5. Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

6. High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

7. Recycable -- Waste scrap molding board could be recycled.

Product Photos/ plastic concrete formwork

If you are interested in our plastic formwork , please feel free to contact with us by email. We will quote you the best price.

Please send your project design drawing in AutoCAD file to us, we will help to make formwork solution for you.

Any building drawings is OK, just send us your drawing, we can make the plastic formwork quantity for you.

And we warmly welcome friends from all over the world to visit our factories for business.

- Q: Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Wood-plastic building templates in the construction works more useful, more affordable, more convenient.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- The main advantages are:1, the surface smooth and smooth, high strength, the provincial workers, the expected material, can meet the requirements of clear water concrete template, after stripping without cleaning the surface of the template, thus saving a lot of labor, template flatness can be controlled within 0.3mm, thickness uniformity, Can be controlled within ± 0.3mm, wood than the wood to save 2/3 of the nails.2, good water resistance, toughness, long-term immersion is not layered, water swelling rate of less than 0.06%, in -30 ℃ _ +60 ℃ range of normal use, the use of 6 years of aging of 15%, normal use of 8 Years or more.3, plasticity, according to the design and component size requirements, processing and production of different shapes and different specifications of the template, a curvature of the template for the production of a more simple template can be drilling nails, saws, planing and other wood mold with the same machinability , On-site stitching simple and convenient.4, recyclable use, plastic template to a certain extent can be fully recycled, regardless of the size of the old and new, after processing, can be added to produce a new template

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- The general building materials market have to sell, I hope my answer can help you ~

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template made of what material

- Building template is generally wood template, steel formwork, plastic template (also can be said that the composite template), steel plate high strength, can be reused many times

- Q: Plastic building template where there is an urgent need to solve

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- The support system of the building template should be able to maintain the safety and reliability of the vertical placement of the building template and its own stability under the wind load. The length of the foot adjustment bolt should meet the need to adjust the vertical installation of the template and adjust the self-stabilizing angle. The foot adjustment device should be easy to adjust and turn flexible. Panel should be used not less than 5mm thickness of the production of steel, the material should not be lower than the performance requirements of Q215A, the template of the ribs and back corure should use steel, cold-formed thin-walled steel production, material and steel panel material should be the same brand to ensure Welding performance and structural properties. Panel system, support system, operating platform system and connectors and other components. Composition of the building template The connection between the various systems must be safe and reliable.

Send your message to us

Made in China Plastic Reusable Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords