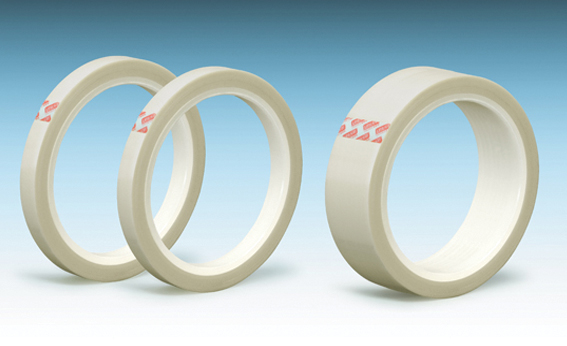

Low price Glass Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CONSTRUCTION:

Backing: Glass Cloth

Adhesive: Adhesive with silicon

TYPICAL PHYSICAL PROPERTIES:

Thickness(adhesives+cloth): 0.18-0.2mm

Width: 3-500mm

Length: 30m

T180° PeelAdhesion to steel: ≥5 N/25mm

Elongation: ≥4.5%

Temperatureresistance: 80-260 oC

Temperatureresistance grade: H

Voltage: 3kv

PACKING:

Core I.D.: 3” (76mm±1)

Jumbo Roll:500mm x 30m

Packaging:Wrapped with corrugated cardboard.

REMARKS:

1. The data above are typical results and subject to change withoutnotice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & LogRoll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be storedat room temperature and be kept away wet and/or heat source.

4. It is essential, as with allpressure-sensitive tapes, that the surface to which the tape is applied must beclean, dry, and free of grease and oil.

5. The users should take test anddo trial-application on the above products before coming into application so asto witness and ensure suitability for their special purpose and technique.

- Q: How to improve the mobility of rubber material

- Fully plasticated rubber use, reduce the Mooney viscosity, improve its ductility.

- Q: What are the differences in the properties of neoprene models?

- Different types of applications are different:CR122 chloroprene rubber: belt, conveyor belt, wire and cable, oil resistant rubber sheet, oil hose, sealing materials and other rubber products.CR232 chloroprene rubber: cable sheath, oil resistant hose, rubber seals, adhesives and so on.CR2441 2442 chloroprene: a raw material used in adhesives for bonding metals, wood, rubber, leather and other materials.CR321 322 type chloroprene rubber cables, plywood, ordinary and hose, oil resistant rubber boots, air duct, cloth, tent cloth, conveyor belt, conveyor belt, rubber seals, agricultural capsule cushion, lifeboat etc..Used as toughening agent for modified acrylate fast structural adhesive (SGA).

- Q: Why is rubber resistant to compression and wear better than metal?

- Rubber crane seen, never seen Iron Hanging

- Q: Why is rubber forest a green desert?

- Rubber is a plant in tropical rain forests, but not native to tropical rainforests in Xishuangbanna. Before the world know it, the growth of rubber trees in South America's Amazon jungle, as long as cut open a gap, there will be a sap from the trunk stream, in the Indian language it is called the "cry of the tree".

- Q: Can rubber products be injection molded and plastic injection functions?

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding. Die casting method. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q: Rubber products on tiles, why tiles yellow?

- Rubber is a mixture of substances that can precipitate and cause yellowing. The term "rubber" is called frost"

- Q: The action of various ingredients in rubber formula

- Cost system: filler, compatibilizer

- Q: Is carbon black and conductive carbon black used in rubber?

- Conductive carbon black is a kind of carbon black used in rubber. After adding rubber, it can make the rubber which has not poured electricity have conductivity characteristics, but the resistivity is higher, and it can't be used as conductor for current load

- Q: What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber is a kind of polymer material made of petroleum and natural gas as raw material and polymerized with diene and olefin as monomers.The main purpose of the industrial synthesis of rubber material is cost saving, improving the properties of rubber products, because the natural rubber products price is more expensive, in order to reduce the cost of enterprises have invested a lot of synthetic rubber materials with low cost.

- Q: How to solve the spray of rubber products?

- For the problem of rubber surface frost spray, Siyuan shoe material company targeted to develop the corresponding treatment agent productionProduct: SY-210C series of rubber, cream, spit and yellow treatment agent, can clean and keep the original surface of rubber products thoroughlyIn two, secondary processing products, but also increase the surface adhesion of the adhesive joint.

Send your message to us

Low price Glass Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords