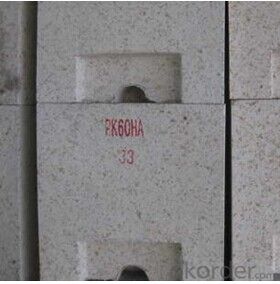

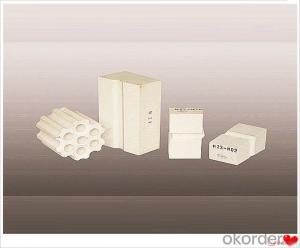

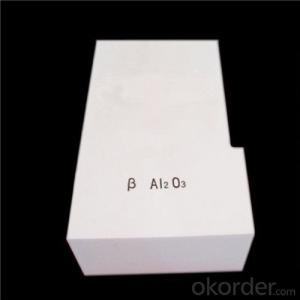

Low Creep Andalusite Fused Cast Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Made from Mullite and andalusite as starting materials, the bricks are processed into shapes by moulding under high pressure and sintering are high temperature, with feature of lower impurity contents, low porosity ,low bulk density,strong strength at high temperature,steady bulk at high temperature,high thermal shock resistance and small creep rate,which are mainly used for HBS.

Brand Index | LHZ-150 | LHZ-145 | LHZ-140 | LHZ-135 |

Al2O3, % ≥ |

|

|

|

|

Fe2O3, %, ≥ | 1.0 | 1.0 | 1.3 | 1.3 |

AP, % ≤ | 1810 | 1810 | 1790 | 1790 |

BD, g/cm³ ≥ |

|

|

|

|

Refractoriness, °C ≥ |

|

|

|

|

CCS, MPa ≥ | 65(55) | 65(55) | 70(60) | 70(60) |

0.2MPa RUL, °C ≥ | 1650 | 1650 | 1630 | 1600 |

PLC(1500°C x 5h), % | 0~+0.5 | 0~+0.5 | 0~+0.5 | 0~+0.5 |

Thermal shock resistance, | 30 | 25 | 25 | 20 |

Creep rate, % ≤ | 0.8 (1500°Cx50h) | 0.8 (1450°Cx50h) | 0.8 (1400°Cx50h) | 0.8 (1400°Cx50h) |

Specifications

1,Low Creep andalusite brick

2,Resisting high temperature.

3,Great bulk density.

4,Low iron content.

- Q: How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q: How are qualitative and qualitative refractories understood?

- Shaped refractory products, such as fired brick, fused brick (Rong Zhuzhuan), refractory insulation bricks, as well as experimental and industrial crucibles, utensils and other special products.

- Q: What are the forming methods of refractory materials?

- Basically there are three kinds: grouting molding, casting molding, machine forming, the three methods are applicable to different types of refractory materials, grouting molding for unshaped refractory

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: What is the face brick

- You should be talking about refractory bricksThe refractory brick brick. Referred to as refractory material has a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size.

- Q: What are kiln bricks?

- Kiln brick masonry brick kiln used brick, brick is a brick kiln.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon aluminum

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- A cuboid with stone walls, with mud firing, mostly red, commonly known as "red brick", there are "blue brick". The size of China's standard clay bricks is 240 x 115 * 53mm. The purpose of this size is to ensure that the length and width of the bricks are 4:2:1 (including the width of the 10mm seam). The thickness of brick to brick brick due to multiple titles, length is 240mm, so the thickness of a brick wall called "24" wall thickness of brick and a half wall called "37" wall thickness is the half brick wall is also known as the "one or two wall". Use bricks online to compare some extreme jokes.

- Q: What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

Send your message to us

Low Creep Andalusite Fused Cast Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords