Low Chrome Grinding Balls for Cement Industry in Good Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package of Low Chrome Grinding Balls for Cement Industry in Good Quality

Steel drum (800-900kg per drum)

flexible container bag (1000kg per bag)

Chemcial Elements of Low Chrome Grinding Balls for Cement Industry in Good Quality

Type and Chemical Composition of Forged Grinding Balls

Name | Chemical Elements (%) | |||||||

C | Si | Mn | Cr | Mo | Cu | P | S | |

Low Cr Balls | 2.2-2.5 | ≤1.2 | 0.5-1 | 0.8-1.8 | 0.6-1 | ≤1 | ≤0.05 | ≤0.05 |

Middle Cr Balls | 2.2-3.3 | ≤1.2 | 0.5-1 | 3-6 | 0.6-1 | ≤1 | ≤0.05 | ≤0.05 |

Normal High Cr | 1.6-3.3 | ≤1.0 | 0.5-1 | 10-13 | 0.8-1 | ≤0.6 | ≤0.05 | ≤0.05 |

Special High Cr | 2.0-3.3 | ≤1.o | 2.1-3 | 15-23 | 0.8-1 | ≤0.6 | ≤0.05 | ≤0.05 |

Material of Low Chrome Grinding Balls for Cement Industry in Good Quality

The high quality round steel.

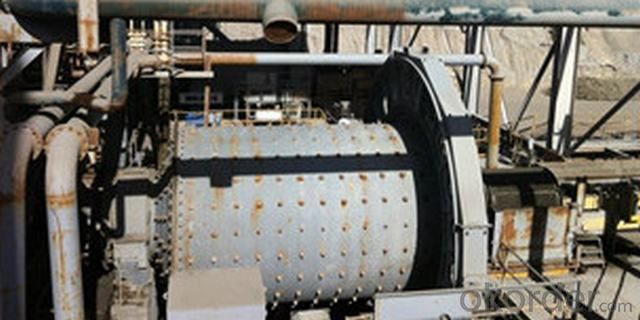

Application of Low Chrome Grinding Balls for Cement Industry in Good Quality

1) CEMENTPLANTS,

2) Metal mining in mines

3) power stations

4) Chemical engineering

- Q: What are the requirements for casting steel castings?

- 1, high quality requirements of the surface or the main processing surface should be placed below.

- Q: What is the difference between forging parts and casting parts?

- The casting parts are low in cost and short in production period. Because the molten iron has good flow properties, complex shapes can be formed. But because there may be sand holes, pores, shrinkage holes and other defects, the quality is unstable, easy to produce many defects, mechanical properties are not forged well, thus affecting the service life.

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- What you say is the difference between rough drawing and processing drawingThere must be a difference between the rough drawings and the rough ones

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Our country or international, in all casting production in 60 ~ 70% by sand casting is produced, of which about 70% is used in the production of clay sand. The main reason is that the cost of sand casting is low compared with other casting method, simple production process and short production cycle. So as the car engine cylinder body the cylinder head, crankshaft castings are produced using clay wet sand molding process. When the wet type can not meet the requirement to consider the use of clay sand table dry sand, dry sand mold or other sand.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: Cause of choking of casting parts

- Is it boiling from the picture? Does it sound like a fire? If not, it's not choking. I feel like choking. The gas doesn't drain out

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa; Mid East;South Asia;Southeast Asia;Eastern Asia;Southern Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

Low Chrome Grinding Balls for Cement Industry in Good Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords