LOW CARBON FERRO CHROME GRADE A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

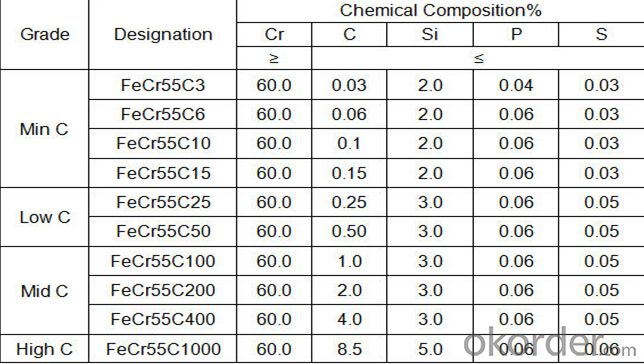

Specifications

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: How to detect carbide material is raw material or recycled material, what is the difference?

- The original material has uniform particle size and stable performance.

- Q: What brand of carbide is used in woodworking tools?

- Carbide YS2T: is used for low speed roughing and milling of heat resistant alloys and semi finishing of titanium alloys, stainless steels, and low alloy steels. Carbide YL10.2: has high flexural strength and good wear resistance, used in low speed rough car and milling heat-resistant alloy, titanium alloy, also can be processed glass fiber reinforced plastic, making PCB micro drilling and so on. YG3/YG6: is suitable for hard alloy cast iron, nonferrous metals and their alloys and non metallic materials during continuous cutting fine cars, semi refined car, suitable for small section iron fine car, and can be used for the coarse thread, steel, nonferrous metals, wet lubrication tensile alloy wire and non metal wire drilling etc..

- Q: What is the difference between them?From hardness, abrasion resistance analysis!

- Is the use of metal carbide hard alloy with high heat resistance and high wear resistance (WC tungsten carbide, titanium carbide, tantalum niobium carbide TiC TaC, NbC etc.) and metal binder (cobalt, nickel and molybdenum) powder metallurgy products under high temperature sintering. Its hardness is 93 HRA8, high temperature resistance of 850 ~ 1000 C, has good abrasion resistance, allowing the use of the cutting speed can reach 100 ~ 300m / min, can be a variety of materials including machining hardened steel, hard alloy is commonly used tungsten cobalt (YG), tungsten titanium cobalt (YT) and general hard alloy (YW) three.Diamond is an allotrope of carbon, natural diamond and diamond two.

- Q: HSS clip can clamp the hard alloy saw it

- A straight back; often used in fine toothed finishing mills. Both the curve and the back teeth have good strength and can bear heavy cutting load. They are often used in coarse tooth mills.Relieving cutterThe back is made by the method of shovel (or grinding), which is machined into the back of the spiral of Archimedes. The cutter only needs to be regrinding before it is blunt, and the original tooth shape can be kept unchanged. It is used to make all kinds of formed milling cutters such as gears and milling cutters.

- Q: Dalian enterprises now need 16.3 and 19.3 mm in diameter, the whole cold hard alloy bit, where can I find buyers? Leave a contact

- Xi'an Jie Electrical Machinery Co., Ltd. internal cooling alloy drill, factory direct sales

- Q: What are the types and specifications of carbide cutters?

- The main components are tungsten carbide, titanium carbide (TiC) and cobaltThe grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide.For example, YT15 is a tungsten titanium cobalt carbide that represents an average WTi = 15% and the remainder is tungsten carbide and cobalt content

- Q: Make cutting dosage

- But modern machining, has no strict distinction between the T and G class, but in different types of processed materials and processing conditions, different ways such as the use of different materials, and with appropriate coating, to reduce the cost requirements.Cutting parameters need to be selected according to different cutting occasions and different materials to be machined.

- Q: What are the fields of nano WC Cemented Carbides applied?

- Nano WC-Co hard alloy, because of its special wear resistance, high hardness, and fracture toughness and excellent compressive strength have been widely applied in various fields of modern technology, has been made of integrated circuit board micro drill, dot matrix printer print needle, hole processing tools, woodworking tools, precision mould, drill, hard processing materials tool etc.. The main applications are summarized as follows: (1) metal working. At first, the development of sub micron WC hard alloy is to solve the high temperature alloy hard to machining processing materials, modern nano WC hard alloy is superior in strength and toughness of sub micro alloy, and therefore more suitable for high temperature alloy, titanium alloy, stainless steel, spraying (welding) processing materials, quenching steel, chilled cast iron etc.. The nano WC cemented carbide breaks through the limit of the bending strength of ordinary cemented carbide, which is far lower than that of high speed steel. Its application has been extended to the field of high speed steel.

- Q: What about cemented carbide produced in Zhuzhou? What brand is good?

- Is good at home, as for the brand well of course is diamond, refined into a brand is also good, there are fine into hard alloy sales company, previously entered a large red facade, product is very much, the Diamond Road No. 24-5, hope to help to you.

- Q: Why carbide fracture?

- Hard alloy is made by casting sintering of tungsten and cobalt, nickel, titanium and tungsten powder, cobalt and nickel matrix, and it is easy to break a bonding metal, quality and technology, process equipment, but also related to the amount of metal content and bonding, in short, hard alloy production is very complex, the quality is strictly, in order to produce good toughness, wear-resistant tungsten is a long-term process of exploration, experiment, a link may not have a good grasp of the products are not qualified.

Send your message to us

LOW CARBON FERRO CHROME GRADE A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords