Long Silk Non-Woven Geotextile Waterproofing Membrane for Road from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Non Woven Geotextile Introduction:

Nonwoven geotextiles are manufactured from the extrusion of polypropylene fibres which are then laid down on a manufacturing "bed" and then needle punched to entangle the fibres such that a dimensionally stable product is formed. Some additional thermal treatment is then applied to further improve the strength of the geotextile. Because of this manufacturing process non-woven geotextiles are generally best used in applications of drainage, filtration and protection

3. Non Woven Geotextile Features:

Wide-width rolls

Quality Certified

Proven for use in Main Roads works

Large range to suit the application

4. Non Woven Geotextile Application:

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

(7) water impermeable geomembrane dam or embankment in the lower part of the back or the concrete.

(8) the isolation layer between the road ballast and subgrade, isolation layer or between the embankment and soft foundation.

(9) the isolation layer soil between highway, airport, railway ballast and artificial rockfill and soil fabric.

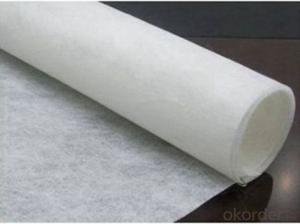

5. Non Woven Geotextile Product Show:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with sediment control?

- Geotextiles help with sediment control by acting as a barrier that prevents the transportation of sediment. They are used to stabilize soil and prevent erosion, allowing water to pass through while trapping sediment and silt. This helps in controlling sediment runoff, reducing soil erosion, and protecting water quality in various construction and environmental projects.

- Q: In ANSYS, geotextile what unit to simulate it?

- I am now doing geotextile simulation, before someone with shell63, I now use, but the shell and the physical contact I did a long time. The

- Q: Is LDPE a geotextile or geomembrane? Answer!

- Geomembrane series, belonging to low density geomembrane

- Q: Can geotextiles be used in shoreline protection?

- Yes, geotextiles can be used in shoreline protection. They are commonly used to stabilize and reinforce shorelines by providing erosion control, preventing soil movement, and promoting vegetation growth. Geotextiles help reduce wave energy, filter sediment, and improve overall stability, making them an effective solution for shoreline protection.

- Q: Are geotextiles suitable for use in gabion walls?

- Yes, geotextiles are suitable for use in gabion walls. They can be used as a filter fabric to prevent soil erosion and improve drainage within the gabion structure. Additionally, geotextiles help to separate different layers of materials, preventing mixing and maintaining the stability of the gabion wall.

- Q: Can geotextiles be used for reinforcement of canal banks?

- Yes, geotextiles can be used for reinforcement of canal banks. Geotextiles are commonly employed in civil engineering projects to enhance the stability and strength of soil and structures. In the case of canal banks, geotextiles can be used to control soil erosion, improve drainage, and provide reinforcement against potential slope failures. They are effective in distributing loads, reducing soil movement, and preventing the loss of fine particles, which ultimately helps in maintaining the integrity and stability of canal banks.

- Q: How are geotextiles manufactured?

- Geotextiles are manufactured through a process called needle-punching, where synthetic fibers such as polyester or polypropylene are mechanically interlocked together using needles. This method creates a strong and durable fabric with various applications in civil engineering, landscaping, and erosion control.

- Q: How do geotextiles help with erosion control in coastal dunes?

- Geotextiles help with erosion control in coastal dunes by acting as a barrier that prevents the loss of sand and sediment. They are placed on the surface of the dunes to stabilize the sand and provide reinforcement, reducing erosion caused by wind and water. Additionally, geotextiles promote the growth of vegetation by trapping sand and providing a stable base for plants to establish roots, further enhancing erosion control efforts.

- Q: Where is the sale of geotextiles in Tibet?

- Tibet geotextile, a variety of specifications, & lt; Ji Han irrigation pit thieves ghosts and bursonoids p & gt;

- Q: Small-scale geotextile and geotextile materials have no effect on environmental protection?

- The impact on the environment is certain, but the benefits outweigh the disadvantages. Geotextile production for environmental protection is both convenient and safe, has been widely used to solve the roadbed subsidence and frosting mud problem, for earth and rock dam drainage system, underground drainage pipes, soft foundation reinforcement, a variety of embankment slope slope And other works of the filter layer. In addition, it can also be used for soil reinforcement materials, so that the soft foundation reinforcement or the construction of light retaining wall, at the same time, but also reduce the embankment under the pore water pressure. And so on, not only to contribute to the cause of environmental protection, but also to stimulate economic development. Geotechnical materials development and application are very good, very broad development prospects. Hope to adopt.

Send your message to us

Long Silk Non-Woven Geotextile Waterproofing Membrane for Road from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords