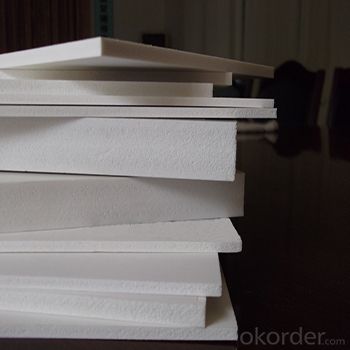

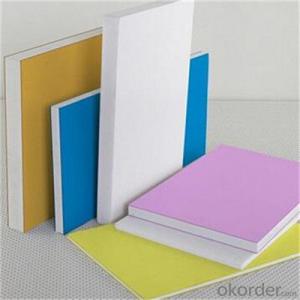

Plastic Sheets - Lightweight PVC Foam Sheet Printing for Outdoor Boards

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

pecifiation of PVC foam board can be produced by our PVC foam board machine:

Width: 915mm to 1830mm

Thicness: 1-33mm

Density: 0.45-0.9g/cm3

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Production flow of PVC/WPC foam board:

Material batching mixing_extruding_molding_vacuum calibrating and cooling_hauling_cutting- final WPC foam boards

Popular Surface treating ways:

- lamination

- hot stamp printing

photos:

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shipme

- Q: I want to build a faster oven for drying plastic sheets. I currently us an 8'x8' low temp gas oven but need to dry more material faster. I've seen info on a woodworker that built a Microwave dryer for large wood projects and wonder if the same technology can be used to dry plastic. A major concern of course is containing the microwave radiation. I'm open to any safe ideas.

- I think the microwave oven frequency will quickly evaporate water from the surface your plastic, but not other liquids, that contain no water. A specific frequency is best for evaporating each kind of liquid, so perhaps you can use multiple frequencies. I tried drying some wet kindling wood with our microwave oven, and was disappointed in the results, so perhaps what you heard was an exaggeration. Neil

- Q: i need these answer for my assignment please help me answer these questions

- Charcoal while while glowing becomes luminous object and emits light which has a frequency which is sensed by our eye as red . On the other hand, a ripe rambutan which is a non luminous object and opaque absorbs all light rays except some scattered light rays which are sensed by our eye as red . And hence it looks red. A plastic sheet which is also a non-luminous, but transparent object , allows only light rays that are sensed by our eye as red to pass through it and absorbs all other light rays . ========================

- Q: Can plastic sheets be used for protective screens in electronic devices?

- Yes, plastic sheets can be used as protective screens in electronic devices.

- Q: i have to figure out the price of ONE overheadd projector plastic sheet for school, so how many of these plastic sheets are in a pack ??? please help !!

- Staples sells them in packs of 100 for the write on kind for $37 The kind you can use in a printer in packs of 50 for $40 So I guess the write on kind = 37 cents each ink jet kind = 80 cents each

- Q: Where can i buy big sheets of Coroplast?

- I okorder / ... HTH, Diane B.

- Q: Are plastic sheets resistant to bending under weight?

- Yes, plastic sheets are generally resistant to bending under weight.

- Q: Can plastic sheets be used for protective film applications?

- Yes, plastic sheets can be used for protective film applications. Plastic sheets are often used as a cost-effective solution to protect surfaces from scratches, stains, and other damages. They can be easily applied and removed, providing temporary or long-term protection for a variety of surfaces such as windows, floors, furniture, and electronic screens.

- Q: I have purchased a plastic sheets (similar to the office cair mate ) to put it on the carpet (only on the walk-way). But I don't know (the best way) how do I stick the plastic sheet to the carpet ?. Please help.I have used the packing tape to stick it together. It doesn't work well. Please help

- if you want to save the carpet, take it up. its made to walk on, just use a carpet rake on it once a wk,

- Q: Are plastic sheets fire-resistant?

- No, plastic sheets are not fire-resistant.

- Q: Hello,I will be laying laminate wood flooring over concrete. Can I alternatively use 6 mil or greater plastic sheeting as moisture barrier found in the construction materials aisle instead of flooring? I found one from Lowe's: Item# 64430 Model# C101006BK, Sunbelt 10' x 100' Black 6Mil Plastic Sheeting for $57.30. It is cheaper and thicker than those found next to the wood flooring materials. The box says it is good for vapor barrier. Even the 4 mil type feels thicker than those found at flooring section.Most flooring site mentioned that the minimum is 6 mil. Does that mean any 6 mil plastic sheeting will be acceptable?Thanks.

- Plastic is plastic is plastic. There is no reason you can not use the 6 mil thick stuff but you don't need that much do you? It comes in smaller rolls at the hardware store or Farm N Fleet near me. I just bought a roll the other day that was 10' by 25' for about $17.00. Because you are on a cement floor you may wish to overlap and tape any seams you have. I have seen it come in 15 by 25 too if that would be more the size you need. You still may need the foam pad under the flooring depending upon the type of product you use. I know they make at least one type of flooring that has the pad attached (didn't like it tho).

Send your message to us

Plastic Sheets - Lightweight PVC Foam Sheet Printing for Outdoor Boards

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords