Mark & model : Multi-storey steel structure, light/heavy steel structure (constant section/ variable cross-section welded H-shaped steel, cross column, box beam/box column), steel truss structure, design and construction of grid project, assembled house, mobile house, assembled villa, metallic roof panel, metallic thermal insulation wallboard.

Origin : Asia and Pacific Area China

Quality standard : International

Submit date : 2013-09-23

H.S.Classification : Furniture & Toys Furniture 9405 Lamps & lighting fittings nesoi & parts thereof etc.

Product profile : Light Steel Villa

Specification: Maximum span is 9m

Notes of Product:

The light steel villa is featured as quake-proof, hurricane-proof, environmental-friendly, energy-saving, light structure, low basic bearing capacity and more usable floor area. The composite leading indicator of light steel villa is much better than that of traditional reinforced concrete structure with its excellent performance of thermal-insulating and soundproof.

Quality Standard: Industrial Standard

Origin: China

Commodity Classification: Light Steel Villa

Descriptions Features Application House Type Descriptions

The light steel structure has high stability

The light steel structure load-bearing system adopts the multi-ribbed plate wall structure composed of high-frequency welded galvanized square steels and structural slabs. The thickness of wall structure ranges from 150-300mm. The structure is featured as excellent integrity and light dead weight, which is equipped to fight against the earthquake of larger than 8 degree and hurricane with wind speed of 50m/second.

2. Industrial production

The light steel structure is composed of high-frequency welded galvanized square steel tubes, V-shaped connection elements and fasteners. It is easy to control the quality of all components which are prefabricated in the factory and the size control reaches up to the millimeter level which provides an excellent foundation for the following decoration project.

3. Convenient construction

The construction of light steel structure house fulfills the factory prefabrication and site assembly; 100 percent strength of the house will be achieved as soon as all the components installed without discontinuous construction, improving the productivity hugely; all components are processed accurately according to the drawing; it is easy to learn the technique of installation and the worker shall conduct the construction expertly after two-day training; it is only one to two weeks to complete the installation of the main structure of a villa about 200-300 square meters.

4. Being suitable to the foundations of various geological conditions

The dead load of the light steel structure house takes only a quarter or a fifth of that of the traditional reinforced concrete structure, which could be built on the foundations of lower load-bearing capacity such as the mountainous area or hilly ground without special treatment, cutting the cost of basic construction significantly.

The environment has limit effect on the construction

The construction of light steel structure house is site assembly which could be conducted under various climate environments. The building of the house could be undertaken in most area of China all the year round.

6. Flexible layout of indoor space

Compared with the components of reinforced concrete structure, the steel components of light steel structure house enjoys a higher strength-weight ratio and the house span of which reaches up to more than 9m, offering the dwellers much more flexible layout of the room and making the personalized dwelling come to true.

7. More usable floor area

The thickness of the wall of light steel structure house is around 150mm, which cuts the structural area greatly and increases the usable floor area to 92 percent of total area, 10-15% improvement compared with the traditional building. All tubes of water and power systems could be put up in the wall and floor structures conveniently without extra design and construction.

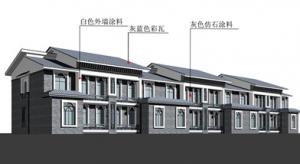

8. Diversified appearances

The excellent workability of steel structure offers architects a good chance for the development of diversified construction designs and styles without the restriction of traditional building materials, enriching the residential landscape greatly.

9. Comfort and energy-saving

The perfect heat-insulating and soundproof structural design with 150mm glass wool thermal barrier is proved to offer the heat-insulating performance of 500mm brick wall and thermal conductivity of the external wall is only 0.36; the soundproof performance of light steel structural walls could achieve more than 50dB; The excellent heat-insulating and soundproof performance not only offers dwellers a comfortable living condition, but saves energy about 60-70percent compared with the traditional reinforced concrete structure house.

10. High reuse of materials

The main structure of light steel house adopts high-frequency welded galvanized square steels which could be recycled completely while the reuse ratio of supporting materials reaches up to more than 80 percent, satisfying the environmental-friendly demands of residential buildings.

Application Anti-wind capability: >1.5 KN/m2

Snow load design value: >1.55 KN/m2

Anti-seismic intensity: 9 degree

Shock resistance of external wall: 250kg concentrated impact load

Fire endurance: >4h

Soundproof performance: >65db (external wall)

Designed service time: 70 years