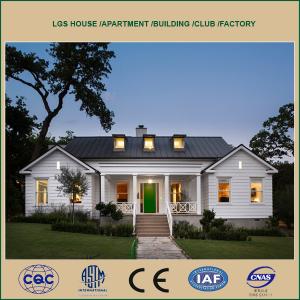

Light Steel House for Xinjiang Clinic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This product belongs to Ligth Steel Frame Structure.

This structure is formed by the dense light steel studs and compound envelop and with all kinds of supprior physical qualities.

Advantages:

1. Flexible combination

2. Easy transportation

3. Fast construction

4. Cost saving

5. Removable & recycle

6. Thermal Insulation

7. Seismic and wind resistance

8. Roof Load-bearing

Packing:

light steel packing: light gauge steel in bulk, decorate panel material in pallet, other fittings all in boxes, loaded into 40' GP and 20' GP on container.

- Q: Sorry, I asked this in the maintenance and repair section, but no luck.Which is better to have in a 2-story home? My last 2-story home was always hotter upstairs than down. (Physics...heat rises)

- the best is more attic isolation so that the heat don't come directly to second floor.

- Q: How do geomembranes handle soil erosion?

- Geomembranes are used as a barrier to prevent soil erosion by providing a durable and impermeable layer. They are designed to withstand the erosive forces of water, wind, and other environmental factors, thereby protecting the soil beneath from being washed away or displaced. Additionally, geomembranes can be anchored or secured in place to further enhance their effectiveness in preventing soil erosion.

- Q: i am having a fence installed, i have quotes from 2 different contractors... one pounds the posts into the ground, the other cements each post into the ground, how deep either go i am not sure... but which way would be more secure long term? the posts are the same as used for a chain link fence (steel posts)... thanks

- Cement 4 sure..pounding them in is weak...not to even mention the added risk of breaking a gas line due to not being able to see what you are doing. Think about it ...with cement you have the added weight for strength...pounding them alone is weak.

- Q: How does steel formwork affect the overall construction schedule and sequencing?

- Steel formwork can have a significant impact on the overall construction schedule and sequencing. Compared to traditional wooden formwork, steel formwork offers several advantages that contribute to faster construction times and improved sequencing. Firstly, steel formwork is highly durable and strong, allowing for multiple reuses without any degradation. This durability reduces the time required for assembly and dismantling, resulting in faster construction progress. Additionally, steel formwork allows for higher pouring rates due to its robustness, enabling larger sections of concrete to be poured at once. This leads to increased productivity and shorter construction schedules. Moreover, steel formwork provides greater accuracy and precision in shaping the concrete structures. The steel panels and frames can be easily adjusted and aligned, ensuring that the forms are correctly positioned and leveled. This exactness significantly reduces the time needed for adjustments or rework, thus improving sequencing and minimizing delays. Furthermore, steel formwork offers flexibility in design and customization. It can be easily modified or adapted to suit different construction requirements and variations in building designs. This flexibility allows for a smoother construction process and eliminates the need for extensive modifications or alterations, saving time and enhancing sequencing. Additionally, steel formwork can withstand harsh weather conditions and extreme temperatures, making it suitable for various construction environments. This resilience eliminates weather-related delays, enabling construction to proceed according to schedule. Overall, the use of steel formwork positively impacts the overall construction schedule and sequencing. Its durability, accuracy, flexibility, and resilience contribute to faster construction progress, reduced rework, improved productivity, and minimized delays. By using steel formwork, construction projects can be completed more efficiently and within the planned timeframe.

- Q: What are the factors that affect the cost-effectiveness of geogrids?

- The factors that affect the cost-effectiveness of geogrids include the initial cost of the geogrid material itself, the installation and construction costs, the expected lifespan and durability of the geogrid, the specific application and site conditions, and the long-term cost savings or benefits achieved by using geogrids compared to alternative solutions. Other factors such as maintenance requirements, environmental considerations, and the availability of skilled labor and expertise can also influence the overall cost-effectiveness of geogrids.

- Q: How do earthwork products contribute to environmental sustainability?

- Earthwork products, such as soil, rocks, and vegetation, play a crucial role in promoting environmental sustainability. Firstly, these products are used in land reclamation and restoration projects, helping to rehabilitate degraded or polluted areas and restore their natural functions. By stabilizing slopes, preventing erosion, and improving soil quality, earthwork products contribute to the preservation of biodiversity and the protection of ecosystems. Additionally, earthwork products can aid in the implementation of green infrastructure initiatives. For instance, using soil and vegetation in green roofs and walls can enhance energy efficiency, reduce stormwater runoff, and mitigate the urban heat island effect. These practices not only enhance the quality of urban environments but also reduce the demand for energy and water resources, thus promoting sustainable development. Lastly, earthwork products have the potential to contribute to the circular economy by facilitating the reuse and recycling of construction materials. By repurposing excavated soil, rocks, or concrete waste, we can reduce the need for new materials, decrease waste generation, and minimize the carbon footprint associated with extraction and transportation. In summary, earthwork products play a significant role in environmental sustainability by restoring ecosystems, supporting green infrastructure, and fostering the circular economy. By utilizing these products responsibly, we can minimize environmental impacts, conserve natural resources, and create a more sustainable future.

- Q: How to clean the room floor

- When cleaning the surface of the floor, please use a cotton cloth wring dry water, do not use alkaline water, soapy water or organic solvents and other corrosive chemicals.

- Q: How do steel tube couplers prevent scaffolding tubes from bending or deforming under load?

- Steel tube couplers prevent scaffolding tubes from bending or deforming under load by securely connecting and aligning multiple tubes together. This creates a rigid and stable structure that can withstand the weight and forces exerted on the scaffolding. The couplers ensure that the tubes remain in their desired positions, minimizing any potential movement or bending that could compromise the integrity of the scaffold.

- Q: How does steel formwork affect the construction schedule?

- Steel formwork can have a significant impact on the construction schedule. One of the main advantages of steel formwork is its ability to provide a high level of stability and strength, allowing for faster construction processes. This means that the overall construction time can be reduced as compared to traditional formwork methods. Steel formwork is also highly durable and can withstand multiple uses, which means that it can be reused for future projects. This reduces the time and cost associated with procuring and assembling new formwork for each project, further contributing to the efficiency of the construction schedule. Additionally, steel formwork allows for precise and accurate construction, resulting in a higher quality finish. This reduces the need for rework and corrections, ultimately saving time and keeping the project on schedule. Furthermore, steel formwork is known for its flexibility and adaptability. It can be easily adjusted and modified to accommodate changes in design or construction requirements. This allows for a smoother workflow and minimizes delays that may occur due to design changes. However, it is worth noting that the initial setup and installation of steel formwork may require more time and resources compared to other formwork systems. The design and fabrication process for steel formwork can be more complex, requiring careful planning and coordination. Therefore, it is essential to consider these factors during the project planning phase to ensure that the construction schedule is not adversely affected. Overall, steel formwork can greatly expedite the construction schedule by providing strength, durability, precision, and adaptability. However, it is crucial to carefully evaluate the specific project requirements and resources available to ensure the optimal use of steel formwork and minimize any potential disruptions to the construction schedule.

- Q: Pvc floor how much money

- According to the requirements are not the same, the level of different grades, so the price is also different. But the basic price of 25 yuan / square to 150 yuan / square are. The higher the requirements, the higher the grade, the more expensive the price

Send your message to us

Light Steel House for Xinjiang Clinic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches