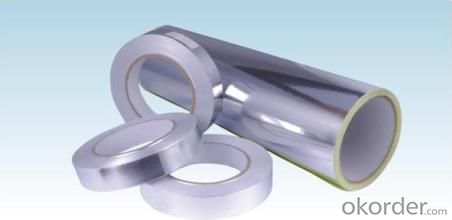

Aluminum Siding Strips - Aluminum Foil Stock for Production of Light Gauge Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Specification:

Alloy:1235/8011/8079

Temper:H14/H16/H24/H26

Thickness:0.2mm-0.3mm

Applications

Super performance, 40u foil tape. Ideal for sealing joints / seams against moisture and vapor on foil jacketing insulation. Suitable for many other permanent sealing, holding, splicing or masking applications requiring the protection offered by a foil backing.Auminum foil can be divided by shape rolled aluminum foil and sheet of aluminum foil.Aluminum foil deep processing of wool roll most is supply, only a handful of handicraft industry with flake aluminum foil packing occasions.

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP

.

- Q: This question asks for a comparison between two types of siding materials: aluminum and steel. It seeks to understand the distinct characteristics that set these two materials apart.

- <p>Aluminum and steel siding are both popular choices for exterior cladding, but they have several differences. Aluminum is lightweight, corrosion-resistant, and requires minimal maintenance, making it ideal for coastal areas. It also comes in a variety of colors and finishes. Steel siding, on the other hand, is more durable and can withstand harsh weather conditions. It is heavier and stronger than aluminum, but it may require more maintenance, such as painting or coating to prevent rust. Steel is also more energy-efficient due to its insulating properties. Both materials offer different benefits and are suitable for different applications based on the climate, design preferences, and budget.</p>

- Q: What benefits can be gained from incorporating aluminum strips in construction projects?

- <p>Aluminum strips offer several advantages in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. They are also resistant to corrosion, making them suitable for outdoor applications and harsh environments. Aluminum strips are easy to work with, allowing for easy installation and customization. They are also energy-efficient, as they reflect heat and can help reduce cooling costs. Additionally, aluminum is recyclable, contributing to sustainability and reducing waste.</p>

- Q: Why is the president of aluminum strip mildew, will affect the performance of the transformer?

- Aluminum with long mildew is actually aluminum is oxidized, the conductivity of alumina is lower than aluminum, so the resistance increases, resulting in increased contact surface heating, may endanger the insulation of the transformer will reduce the performance.

- Q: What types of aluminum strip are best suited for outdoor or exterior applications?

- <p>Yes, certain types of aluminum strip are particularly suitable for exterior applications. These include aluminum strips with high corrosion resistance, such as those with a 3003 or 5052 alloy composition. They are often coated with a protective layer, such as anodizing or a paint finish, to enhance their durability against weather conditions. Additionally, aluminum strips with a thicker gauge are more resistant to denting and wear, making them ideal for exterior use. It's also important to consider the specific environmental conditions of the application, such as exposure to saltwater or extreme temperatures, to select the most appropriate aluminum strip for the job.</p>

- Q: This question asks about the criteria to assess whether a roof can bear the weight of an aluminum strip roof.

- <p>To determine if your roof can support an aluminum strip roof, you should consider the following: First, assess the structural integrity of your existing roof, including the strength of the rafters and the overall condition of the roof structure. Second, calculate the weight of the aluminum strip roof and compare it to the load-bearing capacity of your roof. Third, consult with a structural engineer or roofing professional who can provide a professional assessment. Lastly, ensure that your roof has adequate ventilation and drainage to prevent damage from moisture buildup, which can be exacerbated by the addition of an aluminum strip roof.</p>

- Q: Is it possible to use aluminum strips for decking purposes or for a neighbor's house?

- <p>Yes, you can use aluminum strips for your deck or your neighbor's house, provided it is for decorative or structural purposes approved by local building codes. Aluminum is known for its durability, resistance to corrosion, and low maintenance requirements, making it a popular choice for outdoor applications like decks. However, it's important to check with local regulations and consult with a professional to ensure the proper installation and use of aluminum strips to avoid any safety or legal issues.</p>

- Q: Is it possible to substitute metal sheets for asphalt shingles on a roof?

- <p>Yes, you can use metal sheets to replace asphalt shingles on your roof. Metal roofing is a durable and weather-resistant alternative to asphalt shingles. It offers benefits such as longevity, energy efficiency, and low maintenance. However, it's essential to consider the weight of metal sheets compared to shingles, as it may require structural reinforcement. Additionally, proper installation by a professional is crucial to ensure the roof's integrity and to maximize the benefits of metal roofing.</p>

- Q: Is it possible to use aluminum strips as a material for exterior siding on a building?

- <p>Yes, aluminum strips can be used for siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and comes in various colors and styles, making it a popular choice for residential and commercial buildings. It also has good resistance to harsh weather conditions and does not rot or warp, which are common issues with wood siding.</p>

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: What are the positive impacts on the environment when aluminum strips are used?

- <p>The environmental benefits of using aluminum strips include their recyclability, which reduces waste and conserves resources. Aluminum is highly recyclable, and its recycling process requires significantly less energy compared to producing new aluminum from raw materials. This leads to reduced greenhouse gas emissions and lower energy consumption. Additionally, aluminum strips are lightweight, which can decrease the carbon footprint associated with transportation. They are also corrosion-resistant, reducing the need for maintenance and replacement, and can be used in various applications, such as construction and packaging, to create more sustainable and eco-friendly products.</p>

Send your message to us

Aluminum Siding Strips - Aluminum Foil Stock for Production of Light Gauge Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords