Strips of Aluminum for Industrial Cable & Wire - Aluminium Foil Strips

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Aluminium Foil Strip Specially for Industrial Cable & Wire

*No joint-points per 1000m

*Free samples

*Waterproof and acid attacks

*Surface: With or without gloss/mat effect

*Printed: clear, fastness, non-fade in high-temperature heat seal process

2.Why you want to choose us?

We've been specialized in aluminium foil for more than ten years, we know this product very well, we know what is good, what is the market price.

3.Specification and Application of Aluminium Foil Strip Specially for Industrial Cable & Wire

Alloy: 8011, 1050, 1060, 1035, 1145, 1235, 1100, 1200

Temper: O, H22, H24

Thickness: 0.1-2.0mm

Width: 30-1000mm

Core I. D.: 3" or 6"

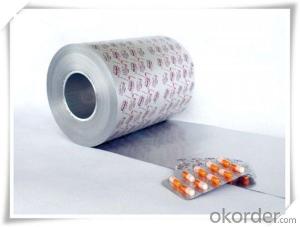

Application: Radio-shielding application of cables, wrapping and shielding application of cable. Cable foil is used as a skin for heat-insulating and electromagnetic shielding to provide high performance for Cable industry

Package: Standard Export wooden Case/Pallet

Remark: Specific requirement of alloy, temper or specification can be discussed at your request.

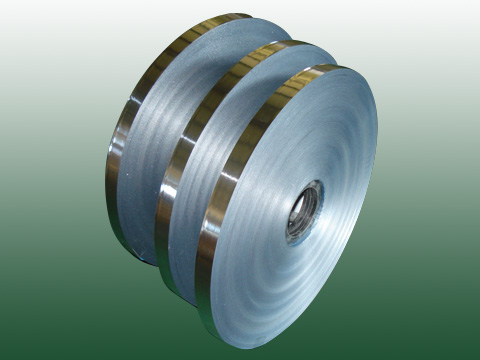

4.Pictures:

5.FAQ:

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: Is it possible to use aluminum strips in decorative applications?

- <p>Yes, aluminum strips can be used for decorative purposes. They are lightweight, durable, and available in various colors and finishes, making them suitable for a range of decorative applications. Aluminum strips are often used in interior design for trims, moldings, and accents, as well as in exterior applications such as facades and signage. Their resistance to corrosion and ease of maintenance also make them a practical choice for decorative elements in both residential and commercial settings.</p>

- Q: Is it possible to manufacture high-quality aluminum strips exclusively from recycled materials?

- <p>Yes, high-quality aluminum strips can be made from recycled materials. The recycling process allows for the production of aluminum that is often indistinguishable from primary aluminum in terms of quality. Recycling aluminum is more energy-efficient and has a lower environmental impact compared to mining and refining new aluminum. The process involves melting the scrap aluminum, which can be sourced from various products, and then casting it into new forms, such as strips. This not only conserves resources but also reduces waste, making it a sustainable practice in the aluminum industry.</p>

- Q: Can metal roofing materials be reused or recycled after they have been installed and used?

- <p>Yes, metal roofing materials can indeed be recycled after installation. Metal is one of the most recycled materials globally, and its recycling process is both efficient and environmentally friendly. When metal roofing reaches the end of its life, it can be collected, processed, and turned into new metal products, including new roofing materials. This recycling process helps conserve natural resources and reduces waste in landfills. The high recycled content of metal can also contribute to the sustainability and green credentials of construction projects.</p>

- Q: What is the ease of bending aluminum strips and what factors might affect this?

- <p>Aluminum strips can be bent relatively easily due to their malleability. The ease of bending depends on the alloy type, thickness, and temperature. Pure aluminum is softer and more ductile, making it easier to bend than aluminum alloys. Thinner strips are also easier to bend than thicker ones. Heating aluminum can increase its ductility, making it easier to bend without breaking. However, excessive force or improper bending can cause the strip to crack or deform.</p>

- Q: What is the chemical composition represented by the formula for aluminum strips?

- <p>The chemical formula for aluminum strips is simply Al. Aluminum is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, soft, nonmagnetic, and ductile metal in group 13 of the periodic table. Aluminum strips are made of this single element and do not contain any other elements or compounds.</p>

- Q: This question asks for the distinctions between a roof made from an aluminum strip and a general metal roof. It seeks to understand the specific characteristics that differentiate these two types of roofing materials.

- <p>An aluminum strip roof is a specific type of metal roof, characterized by its lightweight and flexibility. Aluminum strips are often used for their corrosion resistance and durability. They are typically interlocking and can be easily bent to fit various roof shapes. In contrast, a metal roof is a broader category that includes various types of metal materials, such as steel, zinc, or copper, used for roofing. Metal roofs can be made from solid sheets, tiles, or strips, and they offer different levels of weight, durability, and maintenance requirements. While both are long-lasting and resistant to weather, the choice between an aluminum strip roof and other metal roofs often comes down to specific project needs, cost, and aesthetic preferences.</p>

- Q: Is it possible to use aluminum strips for creating electrical connections?

- <p>While it is technically possible to use aluminum strips to make electrical connections, it is not generally recommended due to several reasons. Aluminum has a higher electrical resistance compared to copper, which is the standard material for electrical wiring. It is also more prone to corrosion and can form aluminum oxide, which is an insulator, leading to poor connections over time. Additionally, aluminum expands and contracts more than copper with temperature changes, which can cause connections to loosen. For reliable and safe electrical connections, copper or other approved materials should be used.</p>

- Q: What effect does the aluminum pulley bring to the belt?

- Belt pulley with aluminum, absolutely assured, at present most of the design belt pulley, all with aluminum

- Q: Is it possible to utilize recycled aluminum to fabricate new aluminum strips?

- <p>Yes, recycled aluminum can be used to make new aluminum strips. Recycling aluminum is an efficient process that conserves energy and resources. The recycled aluminum is melted down and then reformed into new shapes, including strips. This process is not only environmentally friendly but also cost-effective, as it requires less energy compared to producing aluminum from raw materials. The recycled aluminum strips maintain the same properties as those made from new aluminum, making them suitable for various applications.</p>

- Q: What is the standard thickness for aluminum strips and what is it commonly used for?

- <p>The thickness of aluminum strips can vary widely depending on their application, but common thicknesses range from 0.005 inches (0.127 mm) to 0.5 inches (12.7 mm). Aluminum strips are typically used in various industries such as construction, automotive, aerospace, and packaging. They are utilized for manufacturing parts, creating foils, and in applications requiring lightweight, strong, and corrosion-resistant materials.</p>

Send your message to us

Strips of Aluminum for Industrial Cable & Wire - Aluminium Foil Strips

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords