LDPE Laminated MPET and Kraft Packing Bags for Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of LDPE Laminated MPET and Kraft Packing Bags for Packing :

LDPE Laminated MPET and Kraft Packing Bags for Packing are processing with imported materials, we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

LDPE Laminated MPET and Kraft Packing Bags for Packing mainly used in the manufacture of thin films, containers, pipes, wire, wire and cable, and other daily necessities, and can be used as high frequency television, radar and other insulating material. the best choice for all kinds of products ‘packaging.

2. Main Features of LDPE Laminated MPET and Kraft Packing Bags for Packing :

Bottom Sealed Flat PE Unprinted Bags is Polyethylene odorless, non-toxic, feels like wax, has excellent resistance to low temperature performance (minimum temperature is -70 ~ -100 °C), good chemical stability, erosion resistant to most acids (not resistant to oxidizing acid), at room temperature not soluble in common solvents, water absorption, excellent electrical insulation properties.

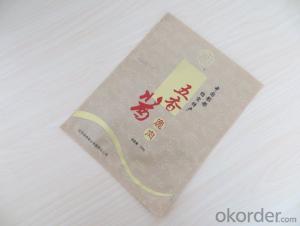

3.LDPE Laminated MPET and Kraft Packing Bags for Packing Images:

4.LDPE Laminated MPET and Kraft Packing Bags for Packing Specification:

1. Material: Laminated material

2.Size:20*750px or Customized

3.Thickness:0.03mm-0.15mm

4.Form:top open bag,ziplock bag, or Unprinted bag

5.FAQ of LDPE Laminated MPET and Kraft Packing Bags for Packing :

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Successful packaging must be eye-catching. This can only be used as a horizontal contrast. In the same environment, the most striking one is the one that can be distinguished from other products at one glance. Also take the moon cake as an example, the Mid Autumn Festival, the general moon cake gift box is red, golden yellow based, above is not the moon, is the flower, most of them are like this. If the design is blue, the package is also shown in the same area. Must be the most striking.

- Q: What is the material of detergent bag?

- Most of these bags are made of PP, PE, OPP, BOPP plastic raw materials. In general, families rarely recycle, just waste or garbage.

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- The simplest and most effective way is to apply a layer of wax to the surface of the zipper, and use the lubrication of the wax to achieve a smooth effect. With a candle on the surface of the zipper back and forth after wiping, and then from the bottom of the repeated several times, the zipper will be smooth.

- Q: What's the raw material of the cement packing bag?

- The raw material is polypropylene resin cement packaging bags, mainly for foreign production of polyethylene (PE), mainly for the domestic production of polypropylene (PP), then add some additives, after the heating wire drawing, then weaving, printing and so on, the higher the quality of the cement bag inner lining!

- Q: Why are some teas not vacuum packed?

- Some tea leaves are not allowed to be packed in vacuum, such as crunchy and fragile tea leaves, easily caking tea leaves, easily deformed tea leaves, sharp edges and corners or higher hardness, and will puncture the tea bags and so on. For example, Yunnan tea, are generally made of tea or tea brick, covering the surface of a layer of paper for simple packaging.

- Q: Should the food packaging bags be labeled with QS markers?

- Hello, you me to answer the question: is not needed, packaging bag manufacturers is the right to own QS logo printing to the packaging bag on your package, the most is according to your request will be posted to the QS carton outside (i.e. certificate below). Your bag can only be printed with your QS logo, or not printed.

- Q: What are the common materials of tea packing bags?

- Synthetic paper cans are the most widely used packaging materials at present. Their advantages are economical, light and beautiful. They are breathable, breathable, and should not be used alone. It is best to use PE bags or aluminium foil laminated bags for internal packing.

- Q: How can the labels affixed to the bags be removed quickly?

- On the label with wind, a few minutes to unveil the label, the label will fall together with adhesive. Even at the stubborn stickers with traces of essential balm, and fingernails pull, usually can quickly clean up the traces.

- Q: What can be easily removed from the words printed on plastic bags?

- Dyes can be classified according to their purpose, state, or origin. Remove the upper part of the plastic bag from the fuel. Refer to

- Q: What is the difference between package material PETAL and VMPET?

- What is the difference between PETAL and VMPET performance?:PETAL material with high barrier, sealing, incense retention, shielding and other functionsVMPET material has higher decoration.

Send your message to us

LDPE Laminated MPET and Kraft Packing Bags for Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords