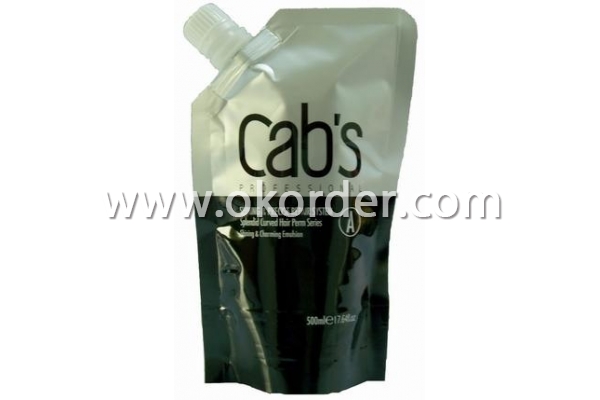

Stand Up Bag With Spout

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000pcs pc

- Supply Capability:

- 500000pcs /month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification Details Of Stand Up Bag With Spout

1)Name: spout pouch, any size, any color

2)Style: stand up with screwed pouch,spout on top

3)Usage: for shampoo or liquid

4)MateriaL: foil bag

5)Printing: up to 9 colours

6)Other: low odor, leaking-proof

7)Alternative: the spout could be welded in the corner, any size spout, or color

Details Of Stand Up Bag With Spout

| Item | Stand Up Bag With Spout | |||||||||

| Bag Shape | Stand up spout pouch | |||||||||

| Material | PET/NY/PE | |||||||||

| Size | 110*170+30*2 mm | |||||||||

| Thickness | 0.13mm | |||||||||

| Printing | 4+customized up to 8 colors | |||||||||

| MOQ | 40K | |||||||||

| Packaging | 200~300pcs/carton or as request | |||||||||

| Usage | this kind of bag can also be used to package liquid food,beverage,hand gel sanitize,etc. | |||||||||

| Advantages | ·Spout pouch,foldable,portable,reuseable | |||||||||

| ·Bottom gusset,to extend the capacity of bag;vivid shape as your design | ||||||||||

| Strong stereoscopic impression to attractive consumers | ||||||||||

| ·Accurate polychrome printing,brings perfect image performance | ||||||||||

| ·High quality with the competitive price and best service | ||||||||||

| ·First grade material and inks,ensure the safety of your products | ||||||||||

| ·Professional suggestion as your requirements. The most suitable packaging for your products. | ||||||||||

| ·SGS certified. FDA certificate can also be made if necessary | ||||||||||

| Trade Terms | EXW;FOB;CNF;CIF 30% deposit, balance against copy of B/L

T/T, Western Union, Paypal, L/C are acceptable | |||||||||

Pictures of Stand Up Bag With Spout

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Successful packaging must be consistent with the product positioning. Today's consumer groups are very different, for example, the elderly and young people on the acceptance of packaging design is very different, but also take moon cake as an example. The elderly may accept the traditional form of packaging (including graphic design, packaging design, structure design and so on) but the young people can accept the moon cake in the cake box, packed in ice cream box, metal box or even installed in the heavy metal in the punk style. You can't imagine an old lady in the supermarket, with a picture of a skull box filled with 8 pieces of moon cakes.

- Q: Why a lot of the packaging bag surface is silver foil?

- The purpose of packing is to look good, because it is food, so it is also because of hygiene.

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags. There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: The difference between a vacuum and a vacuum in a food package

- Vacuum and vacuum is actually a concept, the operation is generally called vacuum, are placed in the vacuum food packaging machine to extract air package a food packaging technology, will conduct disinfection operation in food bagging before or after bagging, its essence is no different.

- Q: Printing process of packaging bag

- When printing, through the extrusion of the scraper, the ink is transferred to the substrate through the mesh of the image part, so as to form the same picture and text as the original. The screen printing equipment is simple and easy to operate. The printing and plate making process is simple, low cost and adaptable. Printing screen printing application scope is broad common: color paintings, posters, name card is designed to cover commodity signs and textile printing and dyeing etc.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- First, it is easy to heat seal, otherwise only aluminum foil can not be sealed;Two, high barrier plastic film preservation effect is also very good, can increase its number of layers, reduce aluminum foil thickness, thereby reducing costs

- Q: How big is the vacuum pack 28*40cm?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- Suitable for your product packaging, like food packaging, of course, thin, see the product, electronic or hardware thick, anti puncture, of course, does not necessarily have to be very thick, suitable for good

- Q: Is there any identification on the vacuum package?

- DOD on demand machine (drop) for short, called ink jet printer. The working principle: the nozzle is made up of several high precision valves. When the word is sprayed, the corresponding valve is opened and closed quickly. The ink is ejected by the constant internal pressure, forming characters or graphics on the surface of the movement.

- Q: Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- It is better not to use a plastic bag directly with a pressure cooker heating, because it is said that plastic bags at high temperatures easy to precipitate toxic substances, so remove plastic bags and then heating for good, so as not to affect the health.

1. Manufacturer Overview

| Location | Foshan, China |

| Year Established | 2005 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Mid East, Northern Europe, Eastern Asia, Eastern Europe, Southeast Asia, Western Europe, Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen; |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 50-100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 9 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stand Up Bag With Spout

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000pcs pc

- Supply Capability:

- 500000pcs /month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords