PE Lamianted Kraft Paper For Food Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

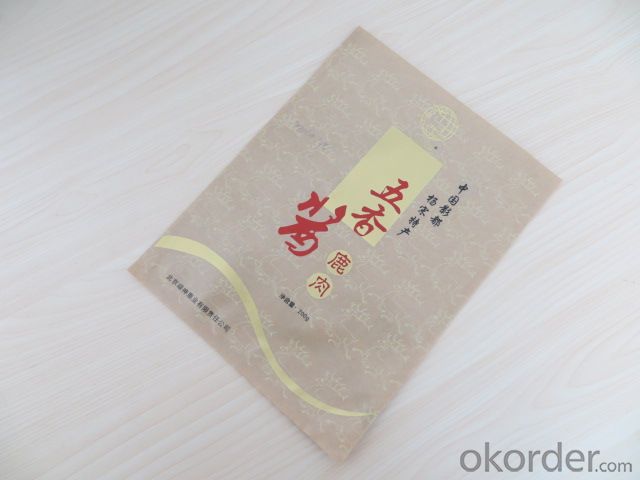

1. Description of PE Lamianted Kraft Paper For Food Packing:

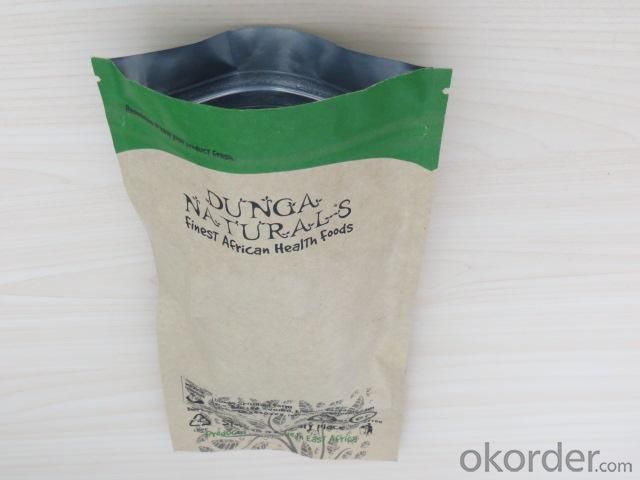

PE Lamianted Kraft Paper For Food Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

PE Lamianted Kraft Paper For Food Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features PE Lamianted Kraft Paper For Food Packing:

Excellent quality control

Experienced facotry produced

SGS passed

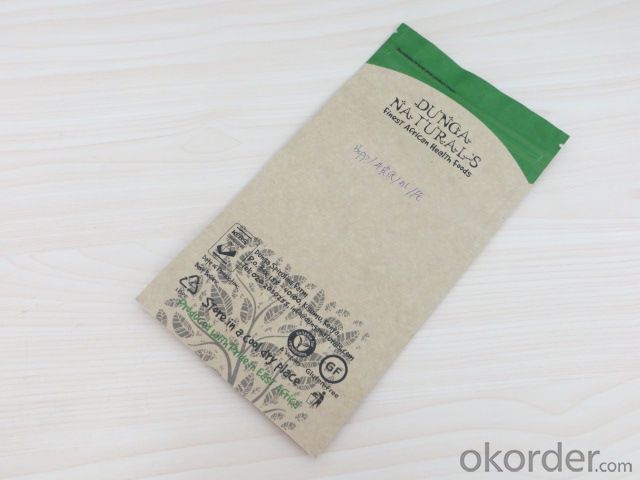

3. PE Lamianted Kraft Paper For Food Packing Photos:

4. PE Lamianted Kraft Paper For Food Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of PE Lamianted Kraft Paper For Food Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Express carton packaging, plastic packaging should be how to deal with?

- Express packaging bags can be used as garbage bags, now online shopping people, in addition to vegetables, fruits this difficult to preserve things, a considerable portion of daily necessities are purchased from the internet. However, the excessive packaging of online shopping packages once troubled people. "Online shopping, a clothing is generally at least two layers of packaging, and the first is the clothes factory comes with transparent plastic bags, and there is a layer of express bags attached to the courier."." Some time ago, "double 11", a friend bought three clothes and a set of speakers, these days have gradually arrived, and summed up a total of eight large plastic bags and two cartons.

- Q: What kind of material is the packing bag of ceramic tile?

- There are three paper kraft paper composite film, color film, color film lamination, lamination, lamination and color printing paper, woven bags and other materials, can do

- Q: How do you determine the 210mm*300mm package and determine its version and length?

- Length 21 cm, width 30, vertical roll length suggest up to cooperate with compound printing equipment

- Q: Can food wrap be heated in a microwave oven?

- There are two sides to consider1. sealed pockets are heated in a microwave oven, and the pressure in the bag is too large to explode! There are all the instructions on the microwave (as well as the eggs, and a hole). The microwave food I eat is also packed in plastic bags, but there's always room for gas2. material of packing bagGeneral contact with food bags, requirements are made of polyethylene (non-toxic, burning candles oil smell), general temperature 130 degrees, this pocket no problem (including the regular supermarket to buy plastic wrap and plastic wrap)However, there are a lot of cheap pocket (for example in the market and vest bag, supermarket cashier for plastic bags) are made of PVC, and can not contact with recycled plastic food; do not to mention (characteristics: cheap, taste, burning acrid smell)And, if it's made of polyethylene, don't heat it up with high oil food

- Q: Three layer coextrusion material for packaging bags

- Three layer co extruded films composed of outer layer of high mechanical strength polyester or polypropylene, elastic material mixed or SEBS intermediate layer is polypropylene with different proportion (SEBS), mixed layer is polypropylene copolymers with SEBS.

- Q: What's the raw material of the cement packing bag?

- Plastic recycling granulator raw materials can be: Polyethylene (greenhouse film, beverage bottles, lining bags, etc.) or polypropylene (old woven bags, packaging bags, bundled rope, etc.).It is recommended to buy products produced by regular manufacturers, and the quality is more guaranteed.

- Q: The difference between a vacuum and a vacuum in a food package

- So, the difference is very clear, is the vacuum packaging bag of the air as much as possible out, but the inflation is the air in the bag is replaced by nitrogen or carbon dioxide and other inert gases, the purpose is as far as possible to reduce food and air contact oxidation process, slow food, avoid food rapid deterioration.

- Q: How big is the vacuum pack 28*40cm?

- 28*40CM is the size of a vacuum packed bag, 40 cm long and 28 cm wide

- Q: Is there any identification on the vacuum package?

- Continue ink jet printer (continuous spraying machine), referred to as CIJ inkjet printer. The principle of operation is that the ink is ejected continuously through a single nozzle and is broken by crystal oscillation to form ink dots. After the ink point is charged and deflected at high pressure, the ink is scanned on the surface of the moving object. Such as Domino A100.

- Q: What can be easily removed from the words printed on plastic bags?

- Plastic packaging is printed on the word if it is ordinary ink with thinner a wipe off, is not easy to erase the organic dye. Such dyes are colored substances. But a coloured substance is not necessarily a dye. What kind of dyes do you use on plastic bags?.

Send your message to us

PE Lamianted Kraft Paper For Food Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords